Hot-Dip Aluzinc Steel Coil with Too High Qualitiy

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-Dip Aluzinc Steel Coil Used for Industry

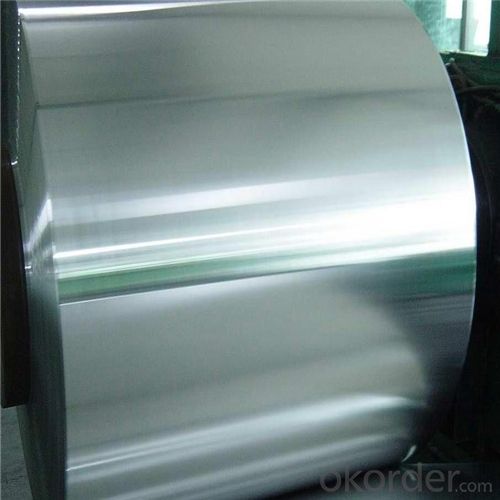

1.Structure of Hot-Dip Aluzinc Steel Coil Description

Hot-dip aluzinc steel sheet is substrated on cold rolled steel in various strength and specification. Coating composition is 55% aluminmum in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent and heat resistance performance.

2.Main Features of the Hot-Dip Aluzinc Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

3. Hot-Dip Aluzinc Steel Coil Images

4. Hot-Dip Aluzinc Steel Coil Specification

Hot-Dip Aluzinc Steel Coil | |

Thicknenss | 0.16mm-3.5mm |

Width | 1250mm max |

Coating mass | 30-185g/㎡ |

Spangle | Regular/Minimized/Zero Spangle |

Coil inner diameter | 508-610mm |

Surface treatment | Chromated/non chromated, Oiled/non oiled, Anti finger print |

5.FAQ of Hot-Dip Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: why do you need to heat steel when hardening, molecules etc etc

- Halps is off base a little. The reason heat is involved in hardening of steels depends, a little bit, on how you are doing the hardening. If you are hardening by work hardening, you do not have to heat it at all. If you are barbarizing (case hardening), the temperature is raised to increase the diffusion rate of carbon into the steel, higher C content - higher hardness. If you are Thur hardening, you have to heat the steel to the austenitizing temperature (so the structure transforms to FCC crystals with higher solubility for C) and then quench it (cool it rapidly enough to freeze the C atoms in the martensite crystal structure). If you slow cool, the steel could end up softer than it started. All of these processes involve atomic level things. If you want to understand them on the atomic level, you need to study physical metallurgy of steels. It is a subject onto itself and is really quite fascinating if you are interested.

- Q: How are steel coils used in the production of agricultural structures?

- Due to their exceptional strength and durability, steel coils find extensive use in the production of agricultural structures. These coils, typically composed of high-quality steel, have various applications within the agricultural industry. One major application of steel coils in agricultural structures involves the construction of buildings and storage facilities. By using steel coils, farmers can create robust frameworks that support the walls and roofs of these structures. The inherent strength of steel allows for the construction of spacious areas without the need for excessive support columns, providing farmers with ample storage space for their crops, machinery, and livestock. Furthermore, steel coils play a crucial role in the manufacturing of agricultural equipment and machinery. Whether it be tractors, plows, harvesters, or irrigation systems, steel coils are essential in the fabrication of these tools. The high tensile strength of steel ensures that these agricultural machines can endure the rigorous conditions of farming, including heavy loads, rough terrains, and exposure to harsh weather elements. Moreover, steel coils are also indispensable in the production of fencing and enclosures for agricultural purposes. Whether it's safeguarding crops from animals or establishing boundaries for livestock, steel coils are a vital component in constructing robust and reliable fences. The strength of steel guarantees that these fences can withstand the pressure from animals, preventing them from breaking through and causing harm to the crops or escaping. In conclusion, steel coils are a vital component in the production of agricultural structures and equipment. Their strength, durability, and versatility make them an ideal material for constructing buildings, manufacturing machinery, and creating fences in the agricultural industry.

- Q: 911 conspiacy theorists. Can fire melt steel?

- So does fuel also generate timed explosions that were heard by firemen? Why do we see melting steel that looks like thermite burning? Does the jet fuel also destroy the entire 80 stories of steel support structure as well? (This is required to account for the free-fall speed of the collapse of three buildings. That's right, three buildings collapsed at near free-fall speeds in NYC in the WTC complex.) The government's conspiracy theory is totally inconsistent with the facts. The only theory that has coherence at the moment is the demolition theory presented by Professor Steven Jones of BYU (Physics). I've seen no credible challenges to the 13 points he presented in an academic paper on this topic. I'd very much like to see a credible explanation for the free-fall collapse of all three buildings.

- Q: What are the common manufacturing defects in steel coils?

- There are several common manufacturing defects that can occur in steel coils, including surface imperfections such as scratches, pits, or dents, dimensional inconsistencies such as uneven thickness or width, edge defects like burrs or cracks, and internal defects such as inclusions or voids. These defects can impact the quality and performance of the steel coils, and manufacturers strive to minimize these issues through quality control measures and inspections.

- Q: How are steel coils used in the production of steel bolts?

- Steel coils are used in the production of steel bolts by being uncoiled and then fed into a machine that cuts and forms the bolts. The coils provide a continuous supply of high-quality steel, ensuring consistent and precise production of bolts.

- Q: How are steel coils used in the shipbuilding industry?

- Steel coils are used in the shipbuilding industry for various purposes such as constructing the ship's hull, decks, and other structural components. These coils are typically cut and shaped to form different sections, plates, or beams that are then welded together to create the ship's framework. Additionally, steel coils are also used for manufacturing equipment, machinery, and other components required for shipbuilding.

- Q: Are steel or graphite clubs better?

- If its for your bf, i would buy steel. Most guys prefer steel because it is more accurate and it think every guy on the pga tour uses steel shafted irons. Steel also usually costs less, which helps. Neither one is better, its just a matter of personal preference.

- Q: What are the common surface treatments for steel coils?

- The common surface treatments for steel coils include galvanizing, painting, and coating with protective films.

- Q: I need to penetrate steel on my car but don't know which bit to use. Are there special bits for steel?

- it's go through steel buddy. But i would imagine that a majority of your standard bits out there will do it. I know there are material specific bits but i would say if you didn't have real expensive drill bits I would try pretty much any of them. If you are talking about the frame of your car or something that thick, then a heavy-duty would be necessary. Don't go drop a lot of money on a diamond bit unless you just keep tearing them up trying to drill through whatever it is you're trying to accomplish. Ive seen wood bits go through some heavy duty metal, so give it a try and save some money.

Send your message to us

Hot-Dip Aluzinc Steel Coil with Too High Qualitiy

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords