Hot-Dip Aluzinc Steel Coil with Super High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-Dip Aluzinc Steel Coil Used for Industry

1.Structure of Hot-Dip Aluzinc Steel Coil Description

Hot-dip aluzinc steel sheet is substrated on cold rolled steel in various strength and specification. Coating composition is 55% aluminmum in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent and heat resistance performance.

2.Main Features of the Hot-Dip Aluzinc Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

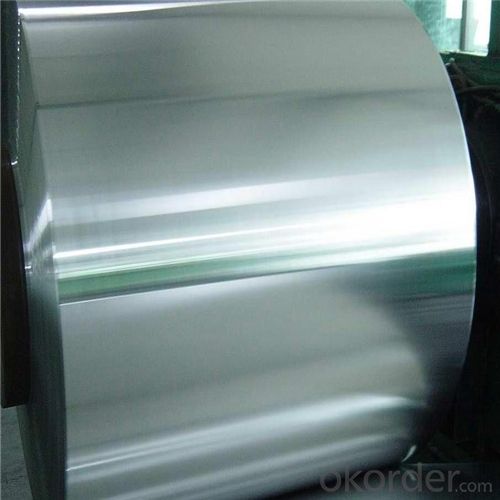

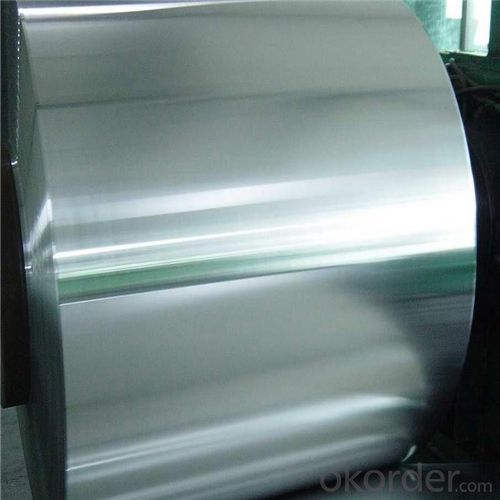

3. Hot-Dip Aluzinc Steel Coil Images

4. Hot-Dip Aluzinc Steel Coil Specification

Hot-Dip Aluzinc Steel Coil | |

Thicknenss | 0.16mm-3.5mm |

Width | 1250mm max |

Coating mass | 30-185g/㎡ |

Spangle | Regular/Minimized/Zero Spangle |

Coil inner diameter | 508-610mm |

Surface treatment | Chromated/non chromated, Oiled/non oiled, Anti finger print |

5.FAQ of Hot-Dip Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What is the tensile strength of steel coils?

- The tensile strength of steel coils varies depending on the specific grade and composition of the steel. However, on average, steel coils have a tensile strength ranging from 400 to 600 megapascals (MPa).

- Q: I'm a big fan of stainless steel and sterling silver, but not of the humidity of the country I'm in. Therefore I sweat more. Gross, I know. I'm buying a necklace chain for my ring.So does sweat contribute to tarnishing of silver and steel? The real kind?

- steel shouldn't really tarnish, it rusts and moisture increases that. Silver tarnishes when exposed to air and sulfur. Moisture increases the process a bit, but it happens anyway. Sweat is not gross, it's a necessary function of your body, otherwise you would die. A lot of sports people wear jewelry and they sweat a lot. If you wear the jewelry all the time, that will prevent the tarnish a bit. If you take it off, clean it (water and dish washing liquid), dry it and put it in a zip lock back to keep it away from air and moisture. In the end, cleaning the jewelry is quick and easy so don't worry about it.

- Q: How are steel coils affected by global trade policies?

- Steel coils can be significantly affected by global trade policies. Trade policies, such as tariffs and quotas, can impact the import and export of steel coils, influencing their availability and pricing in different markets. Changes in trade policies can lead to shifts in supply and demand, affecting the volume and cost of steel coil imports and exports. Additionally, trade policies aimed at protecting domestic industries may create barriers for steel coil imports, potentially affecting the competitiveness of steel coil manufacturers and suppliers.

- Q: What are the different methods of shearing steel coils?

- There exist various approaches to shearing steel coils, each with its own unique pros and cons. Some of the most prevalent methods include: 1. Guillotine Shearing: This technique involves the use of a guillotine-like machine that vertically moves a blade to slice through the steel coil. Guillotine shearing provides high efficiency and accuracy, making it suitable for large-scale industrial production. However, it can lead to deformation or burrs on the cut edges. 2. Rotary Shearing: In rotary shearing, a set of rotating blades is employed to cut through the steel coil. This method enables continuous cutting, making it ideal for high-speed production lines. It ensures a clean and precise cut, but necessitates regular maintenance and blade sharpening. 3. Slitting: Slitting entails passing the steel coil through circular blades that create multiple parallel cuts. This method is commonly used to produce narrower strips from wider coils. It offers great precision and the ability to generate multiple strips simultaneously. However, slitting may result in edge burrs or camber on the strips. 4. Laser Cutting: Laser cutting utilizes a high-powered laser beam to melt or vaporize the steel coil along a predetermined path. This method offers exceptional precision and can cut intricate shapes or patterns. It is commonly employed for specialized applications where accuracy is crucial, although it can be relatively costly. 5. Waterjet Cutting: Waterjet cutting employs a high-pressure stream of water mixed with abrasive particles to cut through the steel coil. This method is versatile and can handle various materials and thicknesses. It is especially useful for cutting heat-sensitive materials or for applications requiring minimal distortion. 6. Plasma Cutting: Plasma cutting involves ionizing a gas to create a plasma arc that melts and blows away the steel coil. This method is fast and efficient, making it suitable for cutting thick steel coils. However, it may produce a wider heat-affected zone compared to other methods. 7. Electrical Discharge Machining (EDM): EDM employs electrical discharges to erode the steel coil and achieve the desired shape. This method is commonly used for intricate or delicate cutting tasks that demand high precision. It is particularly effective for hard materials. Each method of shearing steel coils possesses its own set of advantages and limitations, and the choice depends on factors such as the required precision, speed, material thickness, and the desired end-product.

- Q: How are steel coils used in the production of steel connectors?

- Steel coils are used in the production of steel connectors as they serve as the primary raw material. The coils are unrolled and then processed through various manufacturing techniques, such as cutting, stamping, and bending, to shape them into the desired connector forms. These connectors are crucial components used to join different steel structures together, ensuring strength, stability, and structural integrity in various applications like construction, automotive, and engineering industries.

- Q: I was wondering because i just watched an episode of build it bigger on the discovery channel about the uss George bush, and when they were discribing it they said it was 500 tons of steel and 47,000 tons of aluminum. this kinda struck me as odd because i thought that it was mostly made of steel. and i would think that even if it was mostly aluminum, that the hull would be steel. and i think the hull would weigh more than 500 tons.

- Steel with an aluminum structure above the flight deck. (old shipyard worker)

- Q: So we all know a 1000lb steel ball will sink in water, but if you were to leave the center of the ball hollow and fill with air, if the steel ball was big enough in diameter it should float correct? What size would the steel ball need to be to float?

- sure, if the volume of air is about 7 times the volume of steel, the specific weight of the steel/air system would be below 1.0 and it will float. How do you think ships float?

- Q: How are steel coils distributed globally?

- Steel coils are distributed globally through various means such as shipping, rail, and truck transportation. They are typically transported in bulk quantities to steel processing plants, construction sites, and manufacturing facilities worldwide. Distribution channels and logistics networks play a crucial role in ensuring efficient and timely delivery of steel coils to meet the demands of different industries and markets across the globe.

- Q: How are steel coils used in the production of household appliances?

- Steel coils are used in the production of household appliances as they are a primary material for manufacturing various components like frames, panels, and cabinets. The coils are typically processed and formed into the desired shapes, providing strength, durability, and structural stability to appliances such as refrigerators, washers, dryers, and ovens.

- Q: I have a knife with 154cm steel on it and I always here that you should put oil on it to keep it from rusting but I am just wondering what kind of oil? And how do I apply it and do I just leave it on there?

- There are several grades of steel and other types of metals used in knives. Like another user said, if it is something like 420 Stainless Steel (a very common knife steel grade), then you should not have to worry about it rusting. I still apply oil to my stainless steel knives though to keep the action smooth. Non-stainless will require oil to prevent rust if you are planning on using them heavily. There is a such thing as knife oil and you can find it online. A lot of car or sportting lubricants will work though. I use Rem Oil, a popular gun oil that you can find at Wally World for about $3 a can. Disassemble your knife. Use a solvent and a cleaning solution to clean off the old oil, dirt, and gunk. I use Hoppes solvent (a solvent that can be found at Wal-Mart for a few bucks) and either pour it into a small shot-glass and dip a toothbrush in it, dampen a wash-rag with it, or pour some in the cap and dab a cotton swab on it. Using one of these tools, I swab down my knives completely, focusing mainly on moving parts and parts of the knife that experiences high abrasion (the lock of a liner lock knife for example). Then I spray it down with Rem Oil. Reassemble the knife and let it sit overnight. The next day, I'll rub off any excess oil from the grips. Usually though, the knife is ready to rock the moment I reassemble it. So that's cleaning knives in a nutshell: take it apart, clean off the old oil and dirt, re-oil it with gun oil, then put it back together.

Send your message to us

Hot-Dip Aluzinc Steel Coil with Super High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords