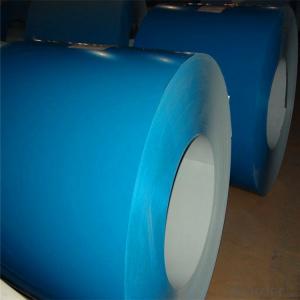

Hot-dip Aluzinc Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product | Hot-dip Aluzinc Steel Sheet |

Thickness | 0.3-3.5mm |

Thickness tolerance | +/- 0.02mm , |

Width | 600-1500mm |

Width tolerance | +/- 2mm |

Length | As to client's require |

Aluzinc coating | 30g-150g |

Standard | ASTM, AISI, DIN, GB,JIS |

Grade | SGCC,DC51D,DX51D,DX52D,,SGCD,Q195,Q235,SGHC,DX54D, S350 GD, S450 GD,S550 GD ect. |

Type | steel sheets/ plates |

Technique | Hot rolled, cold rolled, galvalume / Alu-zinc |

Spangle type | Mini/regular/zero spangle |

Surface treatment | Chromed with passivation / environmental chromed |

Oiled/slightly oiled/ dry/ anti-fingerprint / skinpassed | |

Packing | Standard export packing or following customer's demand |

Delivery Detail | within 40 days after receiving deposit |

Min order | 50 tons |

Coil weight | 3-6 tons |

Grade | Tension Test | ||

Yield Strength (MPa) | Tensile Strength (MPa) | Elongation% No Less Than | |

A80mm | |||

DX51D+AZ | 140-350 | 270-500 | 22 |

DX52D+AZ | 140-300 | 270-420 | 26 |

DX53D+AZ | 140-260 | 270-380 | 30 |

DC54D+AZ | 120-220 | 260-350 | 36 |

Application

1. Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds

2. Appliances Industry Outer clad sheets for washing machine, refrigerator, television, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts

3. Auto Industry Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in highway

4. Industrial Instruments Electric control cabinet, industrial refrigeration equipment, automatic vending machine

Service

1.MOQ:50 ton.

2.Delivery time:40days

3.Payment:30% deposite, 70% in L/C before delivery.

4.We can guarantee 100% inspeciton before the shipment

5.We can 100% supply MTC.

- Q: describe the benifits and disadvantages of the using steel as a material for fasteners

- There are different grades of steels which can suit different application considering corrosion,surrounding atmosphere,pressure,temperature and many more. Let us take the stainless steel fasteners: 1.Resists Rust: The primary advantage to using stainless steel bolts is that they resist rusting. This makes them ideal for outdoor or marine uses, since moisture will not cause them to corrode. Rust basically eats steel and makes it weaker. A rusty, weak bolt can be a serious safety risk, because it can break under a load. 2.Clean: Stainless steel bolts are very easy to clean due to having a higher content of chromium, which creates a lustrous, mirror-like surface that is very smooth. This makes stainless steel an ideal option if aesthetics are an issue. 3.Temperature: Stainless steel has a high melting point, which makes it a good option in machines that are put through immense amounts of heat. The bolts will not fuse together, and can be unfastened when the machines need repairs. Also, in very cold conditions, steel can become brittle. By mixing nickel into the stainless steel, the metal resists becoming brittle at low temperatures. See the source link for details.

- Q: I need to identify a metal. It is rusty so I suspect it is either iron or steel. Since they both have similar densities and are magnetic, how do I tell the difference betweeen steel and iron?

- Iron and Steel Manufacture, technology related to the production of iron and its alloys, particularly those containing a small percentage of carbon. The differences between the various types of iron and steel are sometimes confusing because of the nomenclature used. Steel in general is an alloy of iron and carbon, often with an admixture of other elements. Some alloys that are commercially called irons contain more carbon than commercial steels. Open-hearth iron and wrought iron contain only a few hundredths of 1 percent of carbon. Steels of various types contain from 0.04 percent to 2.25 percent of carbon. Cast iron, malleable cast iron, and pig iron contain amounts of carbon varying from 2 to 4 percent. A special form of malleable iron, containing virtually no carbon, is known as white-heart malleable iron. A special group of iron alloys, known as ferroalloys, is used in the manufacture of iron and steel alloys; they contain from 20 to 80 percent of an alloying element, such as manganese, silicon, or chromium.

- Q: 420 440 1045 or 1065 ive bought knifes with these steel grades and i want to know which one is better.

- SAE 440 is the best. Classified as high grade cutlery steel. There are various grades of 440: A, B, C, and F. 440 A is the most stain resistant while 440 C has the most carbon and can achieve the highest hardness (Best edge Retention). SAE 440 Chemistry: 16 - 18% Chromium, 0.60 - 1.2% Carbon, 0.75% Molybdenum. SAE 420 is pretty good. Classified as cutlery steel, it is a stain resistant grade but has less chromium and significantly less carbon than SAE 440. SAE 420 Chemistry: 12 - 14% Chromium, 0.15% Carbon (min), 0 Molybdenum Chromium is what makes the steel corrosion resistant. It also adds toughness. Molybdenum adds extra corrosion resistance and adds hardenability. So you can see by chemical components that 440 is highest quality although that also means more cost. 1045 and 1065 are low quality steels and you should probably never use them for a knife. The 1 indicates plain carbon steel with little other alloying elements. The last two digits indicate how much carbon is in the steel. 1045 has 0.45% carbon, mid-range hardenability. 1065 has 0.65% carbon, high hardenability. So if I had to choose I would choose 1065 over 1045 but the difference isn't that noticeable. Everything I said here assumes they have all had the optimum Quench and Temper heat-treatment for their chemistry grade.

- Q: How do steel coils contribute to corrosion resistance in products?

- Steel coils contribute to corrosion resistance in products by providing a protective layer that prevents direct contact between the steel surface and corrosive elements in the environment. The coil coating process involves applying a protective coating, such as zinc, to the steel surface, forming a barrier against moisture, chemicals, and other corrosive agents. This coating acts as a sacrificial layer, corroding in place of the steel, thereby extending the lifespan and enhancing the durability of the products.

- Q: I was wondering if anyone knew the grade/type of steel for this product. I'd like to use it as stock for a knife blade, but would like to know the specs so I can determine if it is suitable and, if so, how best to heat treat it.Thanks.PS: I know it isn't stainless, but that leaves a lot of other steel types.

- Flat Steel Bar

- Q: How are steel coils processed before being used in manufacturing?

- Steel coils undergo several processing steps before they are used in manufacturing. The first step is to uncoil the steel coil, which involves unwinding it from a large spool. This is usually done using a machine called a decoiler. Once the coil is uncoiled, it is inspected for any defects or damages. After inspection, the steel coil goes through a process called leveling. This process involves passing the coil through a series of rollers to remove any unevenness or waviness in the steel. Leveling ensures that the coil has a uniform thickness and flat surface, which is crucial for further processing. The next step is to clean the steel coil to remove any impurities, such as rust, oil, or dirt. This is usually done by running the coil through a cleaning line, where it is treated with chemicals and water sprays. The cleaning process ensures that the surface of the coil is free from contaminants, which can affect the quality of the final product. Once the coil is cleaned, it may undergo additional processes depending on the specific requirements of the manufacturing process. For example, the coil may be annealed to improve its ductility and reduce its hardness. Annealing involves heating the coil to a specific temperature and then slowly cooling it. This process helps to relieve internal stresses and improve the steel's mechanical properties. After all the necessary processing steps are completed, the steel coil is ready to be used in manufacturing. It can be further processed into various shapes and forms, such as sheets, plates, or strips, depending on the specific requirements of the manufacturing process. These processed steel coils are then used in a wide range of industries, including automotive, construction, appliances, and machinery.

- Q: How are steel coils used in the manufacturing of automotive doors?

- Steel coils are used in the manufacturing of automotive doors by being shaped and cut into the desired size and shape for the door panels. These coils are then formed into the appropriate curvature and attached to the door frame, providing strength, rigidity, and durability to the door structure.

- Q: case hardening steel is adviced or thru hardening steel is most suitable?

- I don't know your application, but here is some advice. Case hard provides a hard shell around soft steel, depending on the bake, the case is usually .002-.008 thick. (thousands of an inch) Heat treated steel or tool steel is hard all the way thru. Case hardening, provides toughness with flexibility, however, once it's compromised, the part is scrap. Hardend tool steel is extreemly hard throughout and the harder it is, the more brittle it becomes. The application of the part will help you to determine the material needed. For instance; Plastic injection molds are very hard so the hot plastic wont erode them over years of use. Punch Press dies aren't as hard but are tougher to withstand the shock. Machine bolts are case hardened so they can last, but soft enough to allow some stretching during tightening. Either way, the time in mfg will be about the same. Most tool steels today cut like cheese, but take time to be heat treated. Tool steel will cost a bit more than low carbon steel. Low carbon steel is as machinable, and cheaper, but, again, the baking period is as long or longer than tool steel. There are a lot of materials on the market today that maintain the durability of heatreated steel without having to go thru that process. 4140, ( or chrome/moly) comes to mind. There are also some 400 series stainless that work as well, and others. You need to determine strength, flexibility, ease of mfg, cost and repairability when considering which steel to use.

- Q: What are the safety regulations for steel coil production facilities?

- The safety regulations for steel coil production facilities typically include measures such as proper training and certification for employees, regular equipment inspections and maintenance, use of personal protective equipment, implementation of fire prevention and evacuation plans, adherence to hazardous material handling protocols, and compliance with occupational health and safety standards. These regulations aim to minimize the risk of accidents, injuries, and environmental hazards within the facility.

- Q: How are steel coils used in the production of metal facades?

- Steel coils are an essential component in the production of metal facades. These coils are typically made from high-quality steel and serve as the raw material for creating various components of metal facades, such as panels, cladding, and roofing sheets. The steel coils undergo a series of processes during the production of metal facades. Firstly, the coils are uncoiled and flattened to create a flat surface. This helps in ensuring a uniform thickness and smooth texture for the metal facades. The flattened coils are then cut into specific lengths and widths, depending on the design requirements of the facades. After cutting, the steel sheets are subjected to surface treatment processes, such as cleaning, pickling, and coating. These treatments are crucial in enhancing the durability and corrosion resistance of the metal facades. The coatings can be applied through various methods, including galvanization, powder coating, or painting, depending on the desired finish and level of protection required. Once the surface treatment is complete, the steel sheets are shaped and formed into the desired profiles for the metal facades. This can involve processes like roll forming, bending, or stamping, depending on the complexity of the design. These shaping processes give the metal facades their distinctive appearance and structural integrity. Finally, the formed steel sheets are assembled and installed onto the building structure to create the metal facade. This can involve techniques like welding, riveting, or adhesive bonding, depending on the specific requirements of the project. The steel coils, therefore, play a crucial role in providing the necessary raw material for the production of metal facades, which not only enhance the aesthetic appeal of buildings but also provide protection and durability against harsh weather conditions. In summary, steel coils are used in the production of metal facades by serving as the raw material for creating various components, undergoing surface treatments to enhance durability, being shaped into desired profiles, and finally being installed to form the metal facade.

Send your message to us

Hot-dip Aluzinc Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords