Hot-dip Zinc Aluzinc Coated galvanized steel sheet coil For Metal Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 17654 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot –dip aluzinc steel sheet/coil is substrated on cold rolled steel (CRC) in various strength and specification.

Coating composition is 55% aluminum in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance.

The combination of zinc and aluminum in Galvalume enhances both the positive and negative effects of aluminum.

Galvalume has barrier corrosion resistance and heat resistance similar to aluminized material and good bare edge galvanic protection and forming qualities like galvanized material.

Consequently, Galvalume and Galvalume Plus will resist rust, the elements and fire while providing a sturdy and protective covering.

Standard and Grade :

Hot-dip Aluzinc steel coils | ||||

ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 | AS- 1397-2001 | |

Commercial quality | CS | DX51D+AZ | SGLCC | G1+AZ |

Structure steel | SS GRADE 230 | S220GD+AZ | SGLC400 | G250+AZ |

SS GRADE 255 | S250GD+AZ | SGLC440 | G300+AZ | |

SS GRADE 275 | S280GD+AZ | SGLC490 | G450+AZ | |

SS GRADE 340 | S320GD+AZ | SGLC570 | G450+AZ | |

SS GRADE 550 | S350GD+AZ | G500+AZ | ||

S550GD+AZ | G550+AZ | |||

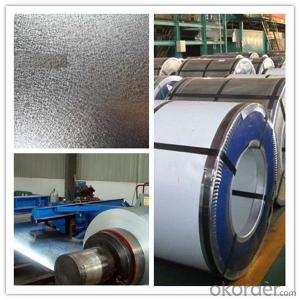

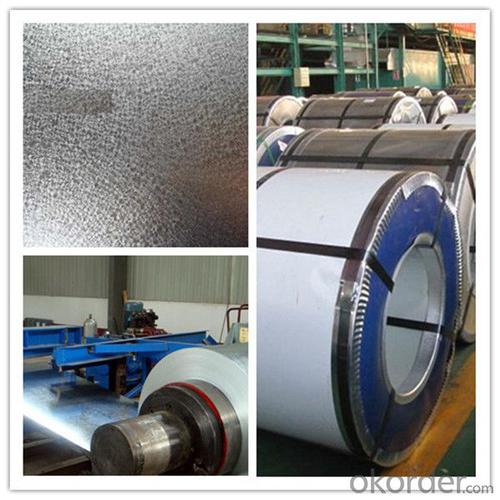

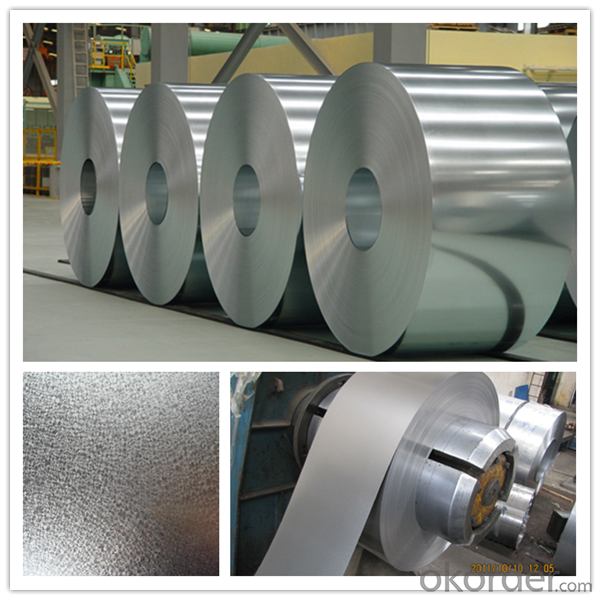

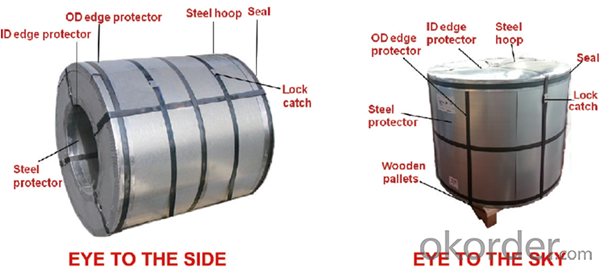

Pictures of Hot-dip Aluzinc steel coils

Application :

Production of cold formed corrugated sheet and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

Packaging & Shipping

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

- Q: I'm a big fan of stainless steel and sterling silver, but not of the humidity of the country I'm in. Therefore I sweat more. Gross, I know. I'm buying a necklace chain for my ring.So does sweat contribute to tarnishing of silver and steel? The real kind?

- steel shouldn't really tarnish, it rusts and moisture increases that. Silver tarnishes when exposed to air and sulfur. Moisture increases the process a bit, but it happens anyway. Sweat is not gross, it's a necessary function of your body, otherwise you would die. A lot of sports people wear jewelry and they sweat a lot. If you wear the jewelry all the time, that will prevent the tarnish a bit. If you take it off, clean it (water and dish washing liquid), dry it and put it in a zip lock back to keep it away from air and moisture. In the end, cleaning the jewelry is quick and easy so don't worry about it.

- Q: All the appliances in my kitchen are stainless steel, and I hate how they look becuase every time I wash them they are full of streaks. Is there a good cleaner made for stainless steel that won't leave streaks?

- Stainless Steel Appliance Cleaning Stainless steel kitchen appliances look best when they're clean and shiny. To clean tough stains and cooking grease, and give them a dazzling shine, try the same detergent you would use when washing the dishes. One formulated to cut grease works especially well.This also works well for general kitchen cleaning.Waterless hand soap also works great as a polish, simply rub on, and polish - no rinsing.=)

- Q: What are the factors affecting the price of steel coils?

- The factors affecting the price of steel coils include the cost of raw materials, such as iron ore and coal, as well as energy prices and transportation costs. Other factors include market demand and supply dynamics, global economic conditions, currency exchange rates, government regulations, and tariffs. Additionally, technological advancements, production capacity, and competition within the steel industry can also influence the price of steel coils.

- Q: PLS tell me all Foam Steel Characteristics and use?Thanks

- Foam steel [often steel foam] is used in applications that require light weight but high rigidity and strength. Watertight doors on modern ships are often made of foam steel. Pressure doors on aircraft are possible uses. As we keep striving for lighter weights in cars, foam steel might have some useful applications in bodies. There is a technical paper online that is in .pdf format that has a good discussion of the process and characteristics of foam steel.

- Q: My musical saw has, despite my best efforts, got little patches of rust on it. How Do I go about removing the rust without spending too much on rust-removal products and without affecting the properties of the steel?

- I would suggest rust removal by electrolysis. Search youtube for that. It probably will not affect the metal but there are no guarantees. I would run a test on another metal. Also this process can be dangerous because hydrogen gas is a by-product - remember not to smoke or be cooking nearby! The Easy way is with BlackStar Rust Remover. It will turn the metal black and convert the rust to metal which can then be painted or left black.

- Q: i have recently gotten into DIY and am planning on making my own knife. My question is what kind of steel would be good to use for heat treating if i plan on using water and not oil in the process.

- Go to junkyard get old leaf spring, cut out knife, start sharpening. Why waste time heat treating steel when the spring steel as already be done.

- Q: How are steel coils used in the production of metal signs?

- Steel coils are used in the production of metal signs as they provide a durable and versatile material for creating the sign's base. The coils are unwound and flattened to form sheets, which are then cut into desired shapes and sizes. These steel sheets can be easily manipulated and bent to create the desired design for the sign. Additionally, the strength and resilience of steel make it an ideal material for outdoor signs, as it can withstand harsh weather conditions and maintain its structural integrity over time.

- Q: I remember my dad saying something about steel toed boots but I forgot =#92; I went and checked out all the stores and got a pair with good ankle support but they also have steel toes. Would this interfere with the shifter or anything? I figure if anything my dirt bike shoes have the steel toes too. Any opinion?

- My work boots are steel caps i ride to work and home in them. I also wear them when I'm too lazy to change into my proper boots.I don't see any dramas with you wearing them they do come in handy for dogs that try to latch onto you. Ride safe.

- Q: I'm ordering a Pair of tongs(a tool used to dig quahogs in bays that scrapes the bottom constantly) and what type of metal would be the best to fabricate it, steel or stainless steel?

- Whilst doing a welding course a few years ago the teacher said stainless steel was not its proper name,it is called Heat and Corossion resistant steel,it come in different grades related to its corossion resistance,priced accordingly.Must be welded properly without introduction of carbon to the weld (carbon pickup) or the weld might not be there next time you look dependant on environment.Generally harder to form than mild steel (low carbon steel) so it will tend to be stronger than lcs for the same cross section.steve

- Q: What are the different coil winding methods used for steel coils?

- Steel coils can be wound using various methods, each having its own benefits and uses. 1. Layer winding is the most commonly employed technique for steel coils. It entails winding the steel strip or sheet in concentric layers to create a coil. This method is suitable for narrow and thin strips, offering excellent coil stability and strength. 2. Cross winding involves winding the steel strip in a crisscross pattern, alternating the direction of each layer. This ensures even stress distribution and prevents coil instability. Cross winding is typically used for wider or thicker steel strips. 3. Spiral winding is utilized for large or heavy steel coils. The steel strip is wound in a spiral pattern, gradually increasing the coil's diameter. This method facilitates easy handling and transportation while providing stability and preventing coil collapse. 4. Toroidal winding is employed to produce toroidal or donut-shaped coils. The steel strip is wound in a circular path, with each layer placed inside the previous one. Toroidal winding is commonly utilized in applications like transformers, where specific coil shape and size are required. 5. Interleaved winding involves intertwining two or more steel strips during the winding process. This method is used to create composite coils with varying materials or thicknesses. It enhances strength, stability, and enables customized designs. The selection of a specific coil winding method depends on factors such as strip thickness, width, tensile strength, and desired coil properties. Each method offers unique advantages and is chosen based on the specific requirements of the steel coil application.

Send your message to us

Hot-dip Zinc Aluzinc Coated galvanized steel sheet coil For Metal Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 17654 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords