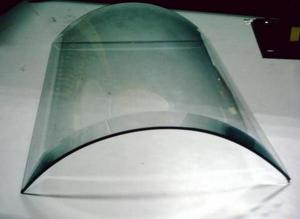

Hot-bent Glass-5

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-bent Glass, also called Curved Glass, is the important model for indoor and outdoor decorations. It is usually tempered for safety.

Features:

1、The accurate arc and smooth curve can satisfy the designers’ requirements for the streamline contour of the building to the greatest extent.

2、Unique shaping technology: flexible rollers are used for glass shaping with automatic accomplishment of corners bigger than 85°.

Specifications:

Thickness: 6-19mm

Size:

2400*2440mm(arc)

300*600mm(arc)

5000*2440mm(arc)

3200*3660mm(arc)

Min. Radius: 450mm

1500mm(for super large)

Min. Corner Radius: 100mm

Min. Corner: 85°

Applications:

Hot-bent Glass is widely used in the fields of shower room, luxurious furniture and architecture.

- Q: What's the raw material for goldfish bowl?

- As for other containers: as long as you can hold water, do not fade, no smell, no harmful substances can be raised

- Q: What is the raw material of glass made of?

- The glass raw materials used for the natural ore, so the manufacture of glass, first of all to all kinds of ore crushing, processing into powder, then according to the glass component, made with the material into the glass melting furnace for melting glass forming liquid. Qualified glass flows through the feed tank and flows out of the feed port to form the stock. The temperature of the stock is 1150~1170 degrees centigrade and the alkali free glass is 1200~1220 degrees centigrade. The material shares every minute near '200 times cut into ball billet. The billet passes through the chute, the ball distributor and the ball plate, and then rolls into different funnels respectively, then falls into a groove formed by three rollers with the same rotating direction. When the ball is rotated on the roller and its surface tension, the ball glass is formed gradually. Its diameter is determined by the thickness, velocity, and shear velocity of the glass stream.

- Q: What chemicals added to the PVB resin powder can be diluted into a transparent liquid?

- Polyvinyl butyral (Polyvinyl butyral) PVB.... PVB resin itself contains many hydroxyl (OH) radicals, with some thermosetting resin (Thermosetting resin) (Cross linking reaction produced a bridging reaction) to improve chemical resistance and film hardness and excellent coating properties. High transparency (Transparent), (elastic), elastic toughness (Toughness), alkali resistance, oil resistance and flexibility, impact resistance and low temperature. Because of its special chemical structure, so there is a strong combination of glass, metal, ceramic, plastic, leather and wood.

- Q: What are the chemicals in glass?

- (some of these ingredients are repeated, and the content of the active ingredients should be carefully calculated when firing the glass) In addition, there are some trace elements, such as metal oxides, used for colored glass, shielding electromagnetic, optical glass and so on. Some other types of special glass materials account for a large proportion of raw materials, and may even contain quartz sand.

- Q: Glass factory raw materials specific to do?

- The glass factory is to produce glass raw materials of dolomite, sandstone, soda ash, mirabilite and so on materials in proportion to reconcile into a block by mechanical device to melt kiln.

- Q: Why is toughened glass broken?

- There are a variety of predisposing factors. Tempered glass explodeFor example, A. before the installation of glass is accidentally damaged, like chipping, knocked the feet, because the glass is tempered around the weak area, its strength even weaker than the non tempered glass, but this part of the damage are not likely to cause the glass immediately burst, but changed the internal stress of glass. When the upper wall is used, the internal stress changes gradually, which breaks the glass.B. such as differences in temperature after installation. As you say, temperature, weather, and so on, will make the internal pressure of the glass partial uneven, thus causing burst.Is there a correct size for the C. installation?. If the installation is too tight, the specifications are not appropriate, it will cause stress changes inside the glass, causing a burst.D. the rest is external force, including impact, extrusion and so on. It's not just human impact, or other things, or even wind in nature. If the glass does not fall on the ground, there will be the point of impact (if it is obvious, there will be explosive, Hu Dieban) these can be invoked, but if in the proceedings can only be said to be a possibility, because you have no evidence to prove that. In the domestic situation, the glass manufacturers generally compensate for the glass trouble.

- Q: There are several appearances of the quality defects of ordinary flat glass

- If molten glass contains gas, it forms bubbles when it is formed. Bubbles mainly affect the transmittance of glass, reduce the mechanical properties of glass, but also affect people's vision, resulting in deformation of the biological image, the main reason is that the purity of raw materials is not enough.

- Q: The preparation process of glass and the basic material and the function of raw materials

- Feldspar provides Al2O3 and enhances chemical stability in glass;Glauber's salt helps the high temperature glass to remove bubbles produced by carbonates in other materials

- Q: Can ordinary white glass (Bai Jiuping) replace quartz glass?

- The glass is the main component in the manufacturing process of quartz sand, quartz sand is combined with other chemical materials at high temperature (1300 degrees Celsius) crystallized after firing the cooling of the body, with a hard, abrasion resistance, corrosion resistance and high transmittance characteristics, its wide application has a long history. The manufacturing technology of the use of glass a thousand li a day, increasing by the clock, glass, doors and windows, lamps, such as high-tech electronic components and space technology, are indispensable glass. Our daily contact with most of the "flat glass is" thick to thin for doors and windows, clocks and the use of medical tests, the manufacturing method is that the furnace in the glass slurry level or traction method (also called float) and vertical traction method. After the dissolution of soluble traction after furnace also has the cooling system, cooling after the completion into a "flat glass, flat glass thickness mainly depends on the speed of traction, traction faster, can be manufactured and thinner. Although the ordinary flat glass from the front appears bright transparent, but from the side near the edge is slightly blue, because the amount of glass color depends on the main raw material in the manufacture of glass - quartz sand and iron content of purity. Generally, the thin glass used in the watch industry is superior in quality but expensive in value, mainly because the material used in quartz sand is superior and the iron content is very low (usually under 3/10000)

- Q: Mobile phone film new flexible toughened glass membrane, really is the glass?

- Toughened glass is a kind of prestressed glass, in order to improve the strength of the glass, the methods commonly used in chemistry or physics, formed on the surface of glass glass under compressive stress, first offset surface stress force, so as to improve the bearing capacity of reinforced glass, its wind, cold, impact etc.. The toughened glass protective film is the highest security level for mobile phone screen protection.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1997 |

| Annual Output Value | |

| Main Markets | Southeast Asia; Mid-East; Africa |

| Company Certifications | CE;RoHS;ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Hot-bent Glass-5

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords