Honeycomb Core Sandwich Panels - Rockwool Sandwich Panel with 980mm 960mm/EPS Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Rockwool

1)Light weight,esay transport

2)Sound Insulation

3)Heat Insulation

4)waterproof

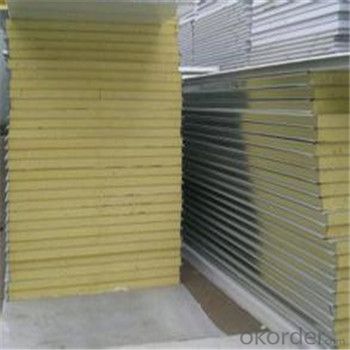

Rockwool sandwich panel with 980mm 960mm/EPS sandwich panel

Specification

1. External\Internal steel panel

Thickness: 0.2~0.5mm

Basic Steel: Galvanized Steel Coil, Zinc Alumine Steel Coil, Stainless Steel Coil

2. Core material

Type : Polysterene

Density: 8-24kg/m3

Width: 980mm 960mm 950mm 1150mm

Length: According to the customers' requests

Side steel strip or not : 0.2~0.5 mm galvanized steel (for roof )

Eps Sandwich Panels

Polystyrene Sandwich panel(also called EPS Sandwich Panel)

Polystyrene is self-extinguishing. EPS Sandwich Panel has excellences of light weight(1/20-1/30 of concrete), heat insulation, rapid construction speed(operate withouthumidity and needn't repeated fitment). It is a new type protection structural material, congregates bearing, heat preservation and water resistance.

EPS sandwich panel specification as below :

Foam thickness | 50mm,75mm,100mm,120mm,150mm,200mm |

Foam density6 | 8-24kgs/m3 |

The top steel sheet and the back steel sheet thickness | 0.2-0.5mm |

Length | Due to continuous molding production,boards may need to be identified under the project in general should not be conditions of transport more than 12000mm |

Advantages of EPS sandwich panel:

1 light weight,

2 easy to install

3 various colour.

4 Sound Insulation,Heat Insulation.

5 The most waterproof.High hardness.

Eps Sandwich Panels

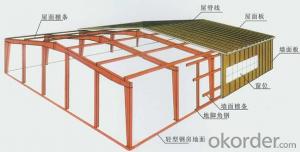

Application

Purification workshop , temeporary office, gymansia, villa, mobile building , guard booth etc. It is widely used for the wall and roof of steel building

Package and delivery

1) Delivery Time: with in15 days after receiving the deposit

2)package:standard export package

Product pictures

FAQ

A, Could be changed the size of the panel?

Yes, we design the size according to your requirement.

B, What is the color of the panel?

All the colors in "RAUL"

- Q: Reinforced concrete and metal sandwich board how much difference

- JGJ130 has regulations. Not more than 0.4L, and not more than 500mm

- Q: What is the difference between the board and the core board? The The

- Cantilevered scaffolding should use biaxial symmetrical section of the steel, which is usually said I-beam models and anchors need to calculate each other, according to the stairs to set the shape

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- On the basis of absorbing and studying the employee 's crisis consciousness and improving the desire, they summarize the ten ideas of self - improvement

- Q: Sandwich panels and Malacca ecological board what is the difference

- Man can pipe the plastic tube can be directly within the tube to detect the actual deformation value

- Q: What is the weight per unit area of 100 thick rock wool sandwich panels?

- The development of safe electricity technical measures and electrical fire prevention measures. ⒋ construction site temporary electricity safety technology files: ⑴ temporary electricity construction organization design and modify the construction organization design all the information. ⑵ technology to the end of information. ⑶ temporary electricity inspection inspection table. ⑷ grounding resistance measurement records. regular inspection (complex) look-up table (site monthly, the company once a quarter). ⑹ earthen worship of the cut of the irrigation pipe tax japonica maintenance work records. ⒌ installation, repair or removal of temporary electricity projects, must be completed by the electrician, electrical grade should be consistent with the degree of engineering and technical complexity to adapt. Second, the electrician: ⒈ electricians must go through professional and safety technical training, by the (city) labor department examination issued a certificate of operation, the prospective independent operation. ⒉ electrician should grasp the basic knowledge of electricity safety and all equipment performance. ⒊ before the job as required to wear personal protective equipment. slightly....

- Q: How does the wall rock wool sandwich panel be installed?

- will be fixed on the wall insulation material, play a warm and warm role in warm technology

- Q: The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- This is hard to say, depends on your house shape, height, height, regular rectangle of the province, the polygon will be more.

- Q: Can sandwich panels be used for ticket booths?

- Yes, sandwich panels can be used for ticket booths. Sandwich panels are made up of two thin outer layers with a thermal insulating core material in between. They are known for their strength, durability, and energy efficiency. These properties make them an ideal choice for various construction applications, including ticket booths. Sandwich panels can provide insulation against extreme temperatures, noise reduction, and fire resistance, which are important features for ticket booths. Additionally, sandwich panels are lightweight, making them easy to transport and install. They can also be customized to fit specific design requirements and can be easily maintained. Therefore, sandwich panels are a suitable and practical option for ticket booths.

- Q: What is the difference between rock wool sandwich panels, EPS sandwich panels and polyurethane sandwich panels?

- When the top of the ventilation tube can not be extended out of the roof, the following ventilation can be used: ①, set the side wall ventilation tube ②, by setting the confluence of the ventilation pipe after the extension of the side wall to extend above the roof ③, set up self-circulation ventilation pipeline system , the following circumstances should be set up ventilation riser: ①, when the drainage pipe to take the sanitary equipment drainage design flow than in Table 449 only set the top of the drainage pipe drainage pipe maximum design drainage capacity ②, the building standards require a high multi-storey residential and public buildings, 10-storey and 10-storey high-rise building life drainage riser , the following drainage pipe should be set up annular ventilation pipe: ①, connecting four and more than four sanitary ware and the length of more than 12m of the drainage pipe ②, connecting 6 and 6 or more toilet toilet cross pipe ③, do not exceed the above provisions, but the nature of the building is important, the use of high requirements or set the device when the ventilation tube , the health, quiet requirements of the building, the living drainage pipe should be set to ventilator tube , the drainage pipe at all levels of the building shall be provided with an annular ventilation pipe, and shall be provided with a main ventilation riser or a secondary ventilation riser for the connection of the layers , ventilation riser shall not accept the equipment of sewage, waste water and rain; not connected with the duct and flue

- Q: What kind of manual sandwich panels can be done? What is the difference between a manual sandwich panel and a mechanism sandwich panel? More

- the bottom of each pole should be set at the bottom or pad

Send your message to us

Honeycomb Core Sandwich Panels - Rockwool Sandwich Panel with 980mm 960mm/EPS Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords