Honesty Long Working Life Silicon Carbide Ceramic Filter Plate

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

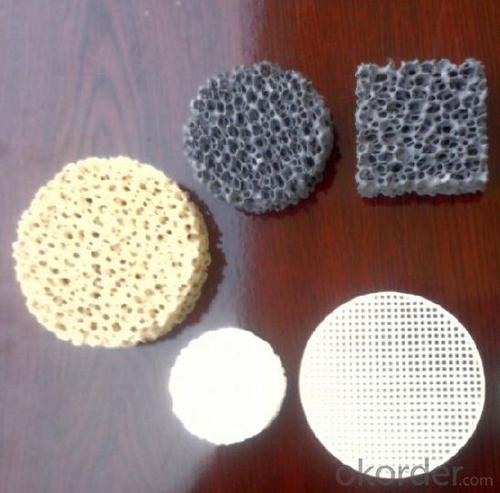

1.Production of ceramic foam filter

Ceramic Foam filters are just developed as a new type molten metal filter to decrease casting flaw in recent years. With its characteristics of light-weight, high mechanical strength, large specific surface areas, high porosity, excellent thermal shock resistance, erode resistance, high-performance, Ceramic Foam filter is designed for filtering impurities from molten Iron & Alloy, nodular cast iron castings, grey iron castings and malleable castings, Bronze casting, etc.

2. Functions of ceramic foam filter

1). Thermal and chemical stability in high temperature,avoiding the chemical reaction with the filtered molten metal;

2). High porosity and good mechanical strength in high temperature due to its pure ceramic composite;

3). Low head loss,easy operation,energy-saving;

4). Making metal liquid flowing at stable speed and avoiding the sputtering and backset,thus increasing the surface quality of the cast part,preventing the pore disfigurement and finally lower down the unqualified rate;

5). Various sizes,shapes,apertures are available for kinds of foundry technique.

3.Physical and chemical properties

Main material | Al2O3 | SiC | |

color | white | Grey black | |

Working temperature | <=1200℃< span=""> | <=1540℃< span=""> | |

Physical parameters | porosity(%) | 80—90 | 80—90 |

Compression strength | >=1.0Mpa | >=2.0Mpa | |

Bulk density | <=0.5g/cm³ | <=0.5g/cm³ | |

size | circular | diameter:10—300mm | diameter:10—250mm |

Square | 10—600mm | 10—305mm | |

thickness | 5—50mm | 10—50mm | |

Pore diameter | ppi | 8—60ppi | 8—60ppi |

mm | 0.1—15mm | 0.1—15mm | |

Main application field | aluminum and aluminum alloy casting | iron and iron alloy casting | |

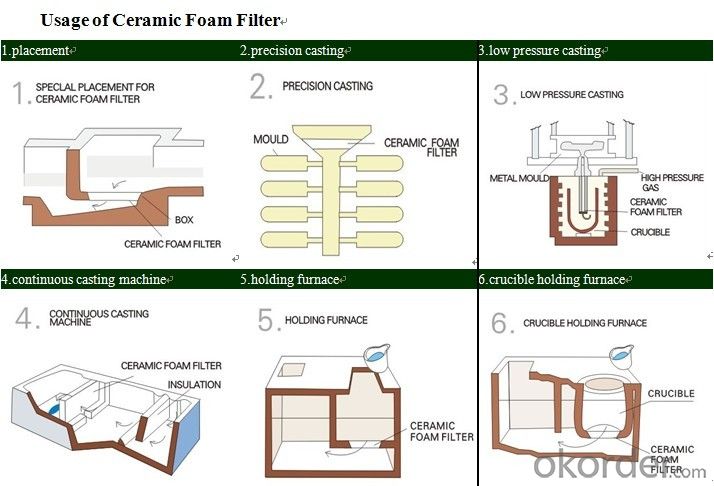

4.Usage of ceramic foam filter

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: The ceramic filter plate is broken. What will happen to the vacuum pump?

- That's a good question. I hope my answer will help you.Ceramic filter ceramic plate broken, nothing more than ceramic plate plug and ceramic plate rupture, you should be the problem of ceramic plate rupture.

- Q: How many degrees does the ceramic filter melt?

- You should say clearly what ceramic you useHowever, as a melting furnace or filter medium, alumina products are the most versatile, but also silicon carbide, corundum, mullite, spinel and so on. They use very high temperatures.

- Q: What happens when the pressure on the filter plate is uneven during backwashing?

- It should be said that the ceramic filter backwash, usually with a certain pressure of clean water to backwash.

- Q: What are the materials that make up the ceramic mold?

- Ceramic membrane, also known as CT film, is one of the solid membrane, the earliest by Japan's large Japanese printing company and Toyo ink company in 1996, the introduction of the market. The ceramic coating is mainly A12O3, Zr02, Ti02 and Si02 of inorganic materials such as porous membrane preparation, the pore size of 250mm. Has good chemical stability, acid resistance, alkali resistance, solvent resistance, high mechanical strength, can reverse flushing: anti microbial ability: high temperature, narrow pore size distribution, higher separation efficiency characteristics, has been widely used in food industry, biological engineering, environmental engineering, chemical industry, petroleum chemical industry, metallurgy industry etc. The market sales, with an annual growth rate of 35% growth. Compared with plastic products of ceramic membrane with similar high cost, but also has many advantages, it is hard to withstand strong, durable, not easy to have chemical resistance village, invasive and high temperature liquid cleaning liquid has a stronger ability to resist, its main drawback is the price expensive. _ complex manufacturing process

- Q: The working principle of ceramic filter

- The working principle and mechanism and the shape of ceramic filter disk vacuum filter is similar to that in the pressure under the action of suspension by filtration medium, particles are trapped cake is formed at the surface of the medium, and the liquid through a filter medium outflow, reached the purpose of solid-liquid separation. The difference is that the filter medium of ceramic filter plate with microporous capillary effect, the capillary force in the pores is larger than the vacuum force applied to microporous keep full liquid state, no matter under what circumstances, the ceramic filter plate does not allow air through, because there is no air through solid-liquid separation, low energy consumption, vacuum a high degree of.

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large

- The concentration, particle size and mud content of the raw materials are not suitable for or due to changes, which are no longer suitable for dehydration using ceramic filters

- Q: How much is the accuracy of 50nm ceramic membrane filtration?

- 50nm refers to the nominal pore size, but it does not mean that the holes in the ceramic membrane are 50nm, but the approximate number of holes. The size of the pores may be between 40~60 and 45 to 55nm. Generally introduced, annotated range, you can also own to detect.

- Q: Does the ceramic factory use hydrochloric acid?

- Ceramic filter comes with a combined cleaning system, usually to ensure backwashing normal, combined cleaning (nitric acid + ultrasonic + backwash) in place.

- Q: Ceramic filter cleaning, sulfuric acid cleaning

- Ceramic filter medium is ceramic, ceramic generally resistant to strong acid, alkali, cleaning, it is best to use nitric acid, hydrochloric acid next, not recommended to use sulfuric acid.

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large?

- The concentration, particle size and mud content of the raw materials are not suitable for or due to changes, which are no longer suitable for dehydration using ceramic filters

Send your message to us

Honesty Long Working Life Silicon Carbide Ceramic Filter Plate

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords