HK 3818 Drawn Cup Needle Roller Bearings HK Series High Precision

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specifications:

Specification | Model No.: HK 3812 |

Brand Name: OEM | |

Size:38*45*18mm | |

Net weight: 0.041kg | |

Material: Chrome steel | |

Cage: Brass, Steel | |

Features: | 1) Precision: P6 P5 P4 P2 |

2) Noise level: Z1, Z2, Z3, Z4 | |

3) Vibration Level: V1, V2, V3, V4 | |

4) Clearance: C2, C3, C4 | |

5) Hardness: 58-63 HRC | |

6) Greese: As your requirement, such as SRL, PS2, Alvania R12 and so on. | |

Packing | 1.Industrial packing: box |

2.Commercial packing: box then into standard carton/wooden Box | |

3.According customer's requirement | |

Payment | T/T, L/C, Western Union |

Delivery time | About 3 to 5 working days |

Services | Warrantee: 1 year |

Samples: available | |

OEM: available | |

Free technical support and after-sales service |

Drawn Cup Needle Roller Bearing :

The outer ring of drawn cup needle roller bearing is punched with the high-quality steel sheet. The outer ring has thin wall.The drawn cup needle roller bearing has the characterstics of small radial section area, large load carring capacity ,less inertia and economic manufacture. It is suitable for small section heght, or when the housing bore isnot used for raceway , this type is recommended to use .The bearing is assembled into the housing bore under a certain pressure without fu rther axial location.

The draw up needle roller bearing generally takes its shaft diameter as the internal raceway .However , the proper LR type inner ring can be used in accordance with application condition.

The draw up needle roller bearing has two structures-with retainer and with full of needles. They are are divided intoopenend type and close-end type. The structure with retainer has the single seal ring and double seal ring .The structure with full of needles has a large load carrying capacity.

Seal/close type Drawn cup needle roller bearings HK:

1.Strong load

2.High performance work

3.Lubrication

4.high speed

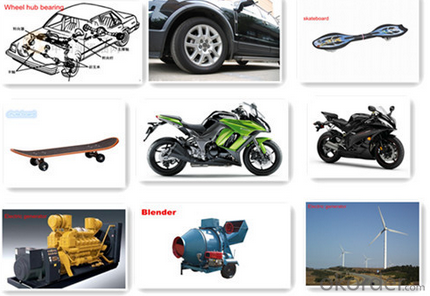

Product Applications:

Needle roller bearings are mainly used in car engines, transmissions, compressors, cranes, etc.

Our Advantages:

1. Excellent and high quality control

2. Prompt delivery

3. Competitive price

4. Small order accepted

5. Customers' drawing or samples accepted

6. OEM service

Shipping:

1.small quantity, can delivery by global express: DHL TNT FedEx ARAMEX EMS UPS.

this is door to door.

2.large quantity, can delivery by air, by sea, this is port to port.

Payment:

T/T, L/C, Money Gram, Payal, Western Union etc.

Lead Time:

Sample Lead-times: generally 3-5 workdays.

Production Lead-times: 3-5 days after get payment or as contract required

FAQ:

WHY CHOOSE US ???

1.More than 28 years export experience

2.Strict quality control

3.Delivery in time

4.OEM service are available with good price

5.Low MOQ

- Q: what is the difference between alloy bearings and plastic bearings?

- Alloy bearings are med out of metal alloys. Plastic bearings are made out of plastic. The metal ones are more durable and last longer, but are heavier than the plastic ones.

- Q: do 98 ford windstars have front wheel bearings?

- Yes. ALL cars have front as well as rear wheel bearings. some are pressed in. some are not, but every vehicle that rolls has to have bearings. Otherwise you would not be able to move the wheels.

- Q: Which one is the better of the two? im looking mostly for speed and for them to be waterproof

- I beleive they are the comparable bearing. Bones website calls the comparable bearing Swiss ceramic and Swiss ceramic labyrinth. Si, i could circulate with those that are the low-priced. in spite of the shown fact that, ceramic bearings are actually not cautioned for highway skating. The ceramic balls can not face up to the extreme results of touchdown from super heights. they are basically used for longboards the place speeds can attain in far greater advantageous than 50mph. in case you will concern your bearings to extreme landings, then decide for the labyrinth if used in a dusty or grimy ecosystem, and the standard Swiss if used indoors, or the place there is little dirt.

- Q: I need to order bearings for the neck of the frame on my bike. I do not know what that piece is called or what i would look for as far as bearings go. Thank you

- i think (yowk bearing) dont think i spelled that right

- Q: I've cleaned my 5000-C but the spool doesn't let line on unless you pull even with everything turned to the lowest. Im trying to figure out if the inside has bearing because the bar in the spool doesn't come out at all. Is this normal or is it suppose to come out once you remove the white gear? Need help asap... I've got two other Ambassadeurs and would love to use the 5000-C as another go to reel. Thanks!!!

- the only bearings on the 5000C are the ones at the ends of the spool shaft. one external, underneath the tension adjustment cap and the other inside the opposite sideplate, held in place by a small metal clip. *the only BALL bearings. other turning contact points have bushings which to a nit picker, are, in fact, bearings.

- Q: I need some iron ball bearings that are about 3-4inches in diameter and I need them to be iron so that I can get some rust build up on them. I tried calling a couple of hardware stores but they usually only carry steel ball bearings and small ones at that. Any idea what kind of store would have LARGE iron ones? Thank you.

- Try King Bearings. If you live in a large town,or a city,they should have a store there. Check out the Yellow Pages.

- Q: I want to take care of my bearings and was wondering what the best lubricant for them was

- ky jelly

- Q: I'm stuck right now can anybody figure this out ?A ship is 31 miles west and 9 miles south of a harbor. What bearing should the captain set to sail directly to harbor ?The answer is N 73.8° E. I just dont know how to get there ...Any help is greatly appreciated !!

- Have you studied sine, cosine and tangent yet? Navigation uses right angled triangles, so sketch the triangle by drawing west from the harbor then south. Draw back to the harbor again to finish the triangle, and label the lengths you know. Conveniently, the bearing is the angle at the bottom. (Compass bearings are measured clockwise from a line pointing north.) The tangent of an angle is the length of the opposite side over the adjacent. So divide 31 miles by 9 miles. 31/9 = 3.444. Make sure your calculator is set to degrees, and press the arctan (tan-1) button. Arctan means the angle whose tangent is.

- Q: What are some fast skateboard bearings bearings?

- If you can spend a lot of money, bones swiss ceramics are the best bearings out there, but run around $120-160. Any bearings that cost around $20 or more are fast, but brand-wise the highest quality are bones. By standards, bones reds are the highest quality for the price. Almost every skater uses bones reds. They cost $20 and are better than flip, panther, and other bearings at the same price. They are quite a lot faster, and a lot more durable as well.

- Q: How do I take a front rims bearings so i can put it in another rim? If your wondering what type of rim for the bike its for bmx bikes. Thanks

- You'll need a tool called a slide hammer and the proper associated fittings to remove rim bearings. Personally, I wouldn't reuse bearings that were removed. These are often cheap enough to just purchase new without worry that soon you'll be replacing them soon. Since you're dealing with bicycle bearings, they're going to be pretty cheap. Industrial and vehicle related bearings will cost more. The slide hammer attachement basically grabs the bearing pack from the inside diameter where the shaft would slide through. the attachment is connected to the slide hammer. you hold the rim down and slide the hammer weight towards you or upwards in a fast motion.

Send your message to us

HK 3818 Drawn Cup Needle Roller Bearings HK Series High Precision

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 900000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches