High Tensile Steel Fabric ASTM BS4449 Rebar Steel Net

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Tensile Steel Fabric ASTM BS4449 Rebar Steel Net

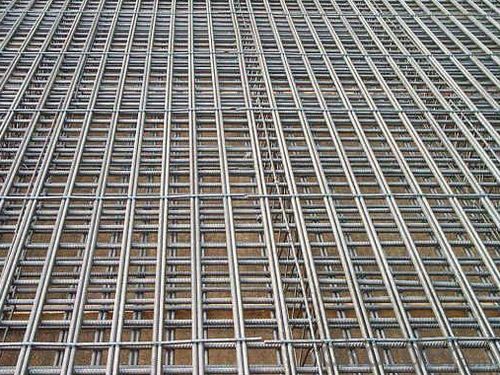

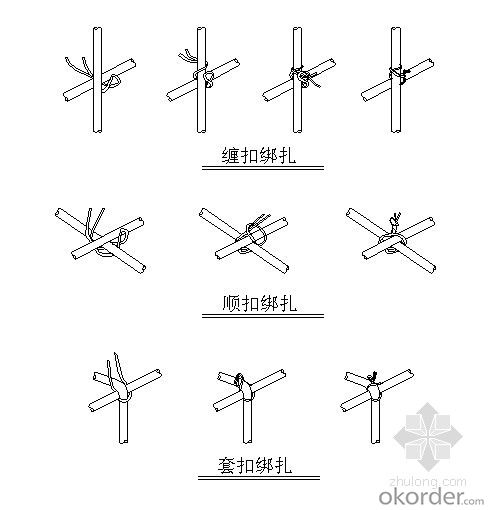

Structure of High Tensile Steel Fabric:

Type | Deformed steel fabric/ TMT bars | MOQ | 500 MT (Trial order accepted) |

Standard Grade | GB1499.2-2007, HRB335, HRB400, HRB500. BS4449/2005, B500A, B500B etc.. ASTM A615 Gr.40, Gr60, KS, SD400, SD500 and so on.. | ||

Technique | Hot rolled continuous casting | Length | 6, 9,12m, or as requested |

Size | 6mm-32mm | Payment terms | T/T, L/C at sight, Usance L/C |

Packing | In bundle | Inspection | Third party inspection accepted |

Trade terms | EXW, FOB, CFR, CIF | Trans terms | FIO, FILO, FLT |

Delivery time | 15-30 days, according to the quantity | Note | Customized service is available (for sizes,length and chemical components etc.). |

Main Features of Steel Fabric:

HRB335 | Chemical composition | C | Mn | Si | S | P |

0.17-0.25 | 1.0-1.6 | 0.4-0.8 | 0.045 Max. | 0.045 Max. | ||

Mechanical Property | Yield strength | Tensile strength | Elongation | |||

≥335 Mpa | ≥455 Mpa | 17% | ||||

HRB400 | Chemical composition | C | Mn | Si | S | P |

0.17-0.25 | 1.2-1.6 | 0.2-0.8 | 0.045 Max. | 0.045 Max. | ||

Mechanical Property | Yield strength | Tensile strength | Elongation | |||

≥400 Mpa | ≥540 Mpa | 16% | ||||

HRB500 | Chemical composition | C | Mn | Si | S | P |

0.25 Max. | 1.6 Max. | 0.8 Max. | 0.045 Max. | 0.045 Max. | ||

Mechanical Property | Yield strength | Tensile strength | Elongation | |||

≥500 Mpa | ≥630 Mpa | 15% | ||||

Specification and Data for Steel Fabric:

Deformed steel fabric | ||||

Diameter (mm) | Theoretical weight (kg/m) | Pieces/Mt (pcs) | Length (m) | Standard |

6 | 0.222 | 375 | 12 | GB1499-48, HRB335, HRB400, HRB500 BS4449-97, Gr.460B,B500

|

8 | 0.395 | 211 | ||

10 | 0.617 | 135 | ||

12 | 0.888 | 94 | ||

14 | 1.21 | 69 | ||

16 | 1.58 | 53 | ||

18 | 2 | 42 | ||

20 | 2.47 | 34 | ||

22 | 2.98 | 28 | ||

25 | 3.85 | 22 | ||

28 | 4.83 | 17 | ||

32 | 6.31 | 13 | ||

36 | 7.99 | 10 | ||

40 | 9.87 | 8 | ||

50 | 15.42 | 5 | ||

FAQ:

Why choose us:

1. More than 10 years experience in this industry

2. 100,000 tons exporting per month

3. Professional foreign trade team

4. OEM&ODM capacity

5. High quality assured & competitive price

6. Try our best to meet your needs & save your budget

7. Very popular in Southeast Asia, Africa, Mid-East and South America etc.

8. VIP membership system, first time customers and long-term cooperation customers can get extra discount on some products.

Picture:

- Q: Can ductile iron pipes be used in geothermal systems?

- Yes, ductile iron pipes can be used in geothermal systems. Ductile iron pipes are known for their high strength and durability, making them a suitable choice for various applications, including geothermal systems. Geothermal systems involve the extraction of heat from the earth's subsurface, which requires a reliable and robust piping system to transport the geothermal fluid. Ductile iron pipes are capable of withstanding high temperatures and pressures, making them ideal for carrying hot geothermal fluids. Additionally, ductile iron pipes have excellent corrosion resistance, which is important for geothermal systems as they often involve the circulation of corrosive fluids. Overall, ductile iron pipes are a viable option for geothermal systems due to their strength, durability, and resistance to high temperatures and corrosion.

- Q: What is the internal lining used in ductile iron pipes?

- The internal lining used in ductile iron pipes is typically a cement mortar lining.

- Q: Are ductile iron pipes suitable for fire protection systems?

- Ductile iron pipes are a perfect choice for fire protection systems. Ductile iron, being a robust and durable material, can endure extreme pressure and temperature fluctuations, making it an ideal option for reliable and long-lasting pipes in fire protection systems. Moreover, ductile iron demonstrates exceptional resistance to corrosion, preventing any deterioration of the pipes and ensuring the integrity of the fire protection system over time. Additionally, the high tensile strength of ductile iron provides added safety advantages, as it can withstand the stress and strain that may arise during a fire incident. Consequently, ductile iron pipes are extensively utilized in fire protection systems across various applications, including commercial buildings, industrial facilities, and residential areas.

- Q: Can ductile iron pipes be used for water tunnel crossings?

- Indeed, water tunnel crossings can utilize ductile iron pipes. Renowned for their robustness, longevity, and immunity to corrosion, ductile iron pipes prove to be an ideal option for diverse purposes, including water tunnel crossings. Their ability to endure immense pressure, external burdens, and soil movements, commonly experienced in tunnel crossings, is commendable. Moreover, ductile iron pipes boast an extended lifespan and necessitate minimal upkeep, rendering them an economical resolution for water tunnel crossings.

- Q: Qianwei County ductile iron pipe which tool to use cutting convenience?

- Cutting method for cutting ductile iron pipes, in order to obtain neat kerf, we should start with a direction of play saw saw to end. If the requirement of the section is not high, the direction of sawing can be changed gradually to reduce the resistance and facilitate cutting in.

- Q: Can the underground cast iron pipes be connected with clamps to form buttress?

- Best not to, because the use of clamp connection way to connect the poor integrity of the pipeline, the base treatment is not in place or uneven settlement, it is easy to produce deformation, resulting in pipe bending deformation, easily leaked from the junction.

- Q: What are the typical bedding and backfill requirements for ductile iron pipes?

- To ensure the correct installation and long-term effectiveness of ductile iron pipes, it is important to adhere to the typical requirements for bedding and backfill. The bedding material should be a granular substance that provides support and evenly distributes the load on the pipe. Suitable materials include sand, gravel, or crushed stone. The bedding material should be placed uniformly and continuously along the bottom of the trench, with a minimum thickness of 6 inches. The width of the bedding layer should be at least 1.5 times the outer diameter of the pipe, or as specified by the pipe manufacturer. Once the bedding is in place, the remaining space around the pipe should be filled with backfill material. This material should also be granular and free from large stones, debris, or organic matter. It should be compacted in 6-inch increments using appropriate compaction equipment. The backfill should be evenly distributed around the pipe, ensuring there are no gaps or voids. Excessive compaction should be avoided to prevent damage or deformation of the pipe. The backfill material should extend at least 12 inches above the top of the pipe. In addition to following the bedding and backfill requirements, it is crucial to adhere to any specific guidelines provided by the pipe manufacturer. These guidelines may include recommendations for specific materials, compaction methods, or additional protective measures. Overall, proper bedding and backfilling of ductile iron pipes are essential for maintaining the structural integrity and preventing damage or failure. By following industry standards and manufacturer specifications, the pipes will perform effectively and last for a long time in various applications.

- Q: How does ductile iron pipe compare to steel pipe in terms of durability?

- Ductile iron pipe and steel pipe possess distinct characteristics, but when it comes to durability, ductile iron pipe holds several advantages over its steel counterpart. To begin with, ductile iron pipe boasts exceptional resistance to corrosion. It incorporates a protective layer of zinc or cement lining that safeguards it against rust and corrosion, enhancing its durability and reducing the likelihood of leaks or failures. Conversely, steel pipe is vulnerable to corrosion, particularly when exposed to moisture or specific chemicals. This susceptibility can lead to structural problems and diminish its overall durability. Furthermore, ductile iron pipe exhibits remarkable impact resistance. It can endure substantial loads and external pressures without cracking or breaking, rendering it suitable for applications in high-traffic areas or situations where the pipe may be subject to accidental impacts. Steel pipe, despite its strength, can be more brittle and prone to fractures under similar circumstances. Moreover, ductile iron pipe boasts a longer service life compared to steel pipe. With proper maintenance, it has been known to endure for over a century, making it a dependable and long-lasting choice for infrastructure projects. Steel pipe, although still durable, may necessitate more frequent inspections and maintenance to ensure its longevity. In conclusion, ductile iron pipe surpasses steel pipe in terms of durability due to its corrosion resistance, impact resistance, and extended service life. Nevertheless, the selection between the two ultimately depends on the specific application, budgetary constraints, and other project requirements.

- Q: What are the typical joint restraint systems used in ductile iron pipes?

- The typical joint restraint systems used in ductile iron pipes are mechanical joint restraints, push-on joint restraints, and restrained joint systems. These systems are designed to prevent pipe separation and movement at the joints, ensuring the integrity and stability of the pipeline.

- Q: How do ductile iron pipes compare to PVC pipes?

- Ductile iron pipes are generally stronger and more durable compared to PVC pipes. They have a higher tensile strength and can withstand higher pressure, making them suitable for more demanding applications such as water mains and sewer lines. PVC pipes, on the other hand, are lightweight, easy to install, and resistant to corrosion, making them a popular choice for household plumbing and irrigation systems. Ultimately, the choice between ductile iron and PVC pipes depends on the specific needs and requirements of the project.

Send your message to us

High Tensile Steel Fabric ASTM BS4449 Rebar Steel Net

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords