BS4449 ASTM A615 DCL Reinforcing Steel Rebar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,ASTM,JIS,GB,DIN,API,EN,BS

Technique:

Cold Rolled,Hot Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

U Channel,Square,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series,300 Series,400 Series,600 Series,SS400-SS490,10#,20#,A53(A,B)

Certification:

ISO,SGS,BV,IBR,RoHS,CE,API,BSI,UL

Thickness:

6-34mm

Width:

6-34mm

Length:

12m

Outer Diameter:

6-34mm

Net Weight:

10kg

Packaging:

seaworthy packaging

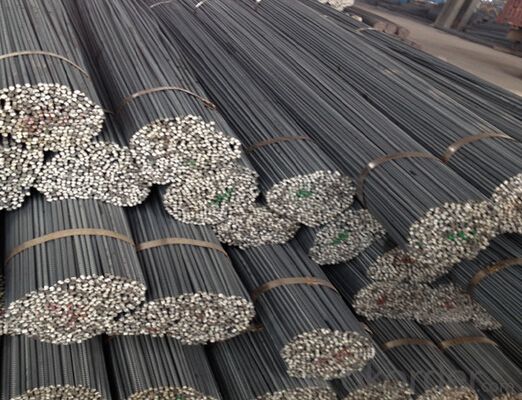

BS4449 ASTM A615 DCL Reinforcing Steel Rebar

Details of the BS4449 ASTM A615 DCL Reinforcing Steel Rebar

| Standard & Grade: | GB1499-98 : HRB335,HRB400,HRB500 |

| BS4449-1997 : GR460,GR500 | |

| CAN/CSA-G30.18-M92 : 400W | |

| ASTM A615 : Gr.40, Gr.60 | |

| Diameter: | 6mm;8mm;10mm;12mm;14mm;16mm;18mm;20mm;22mm;25mm;28mm;30mm;32mm;35mm;40mm |

| Length: | 6m,9m,12m |

| Packing: | Bundle packing |

| Origin: | China |

| Application: | Construction,Road,Machinery processing,Welding fields. |

| Delivery time: | 10-25 days |

| Shipment: | By bulk vessel or Container |

| Documents: | Mill Test Certificate,Commercial Invoice,Packing List,Certificate of Origin |

Company Introduction of the BS4449 ASTM A615 DCL Reinforcing Steel Rebar

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of the BS4449 ASTM A615 DCL Reinforcing Steel Rebar

| Packaging Detail | Sea worthy packing /as per customer's packing instruction |

| Delivery Detail | 15 ~ 40 days after receiving the deposit |

FAQ

| Are you a trading company or manufacturer? | Manufacturer |

| What’s the MOQ? | 1000m2 |

| What’s your delivery time? | 15-20 days after downpayment received |

| Do you Accept OEM service? | Yes |

| what’s your delivery terms? | FOB/CFR/CIF |

| What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

| Western Union acceptable for small amount. | |

| L/C acceptable for large amount. | |

| Scrow ,Paybal,Alipay are also ok | |

| Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

| What's your available port of Shipment? | Main Port, China |

| What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

| Where are your Market? | Covering more than 160 countries in the world |

- Q: What is the national standard of thread steel No. 8?

- Thread steel specifications: generally including the standard grade (type code), steel nominal diameter, nominal weight (quality), the length of the specifications and the allowable difference between the above indicators. China's standard recommended nominal diameter of 6, 8, 10, 12, 16, 20, 25, 32, 40, 50mm thread steel series.

- Q: What is the impact of steel rebars on the aesthetics of a structure?

- Steel rebars, being an essential component of reinforced concrete structures, generally have minimal impact on the aesthetics of a building. They are typically concealed within the structure and remain hidden from view. However, in certain architectural designs where rebars are intentionally exposed, they can contribute to an industrial or modern aesthetic. Overall, the impact of steel rebars on the aesthetics of a structure is largely dependent on the design intent and whether they are meant to be visible or not.

- Q: What is the role of steel rebars in preventing structural vibrations?

- Steel rebars play a crucial role in preventing structural vibrations by providing reinforcement and stability to concrete structures. The rebars, which are embedded within the concrete, enhance the overall strength and rigidity of the structure, making it more resistant to vibrations caused by external factors such as wind, earthquakes, or heavy machinery. The presence of steel rebars helps to distribute and dissipate the energy generated during vibrations, reducing their amplitude and preventing potential structural damage or collapse.

- Q: Is the steel thread stainless steel?

- Steel is known as hot rolled ribbed bar. Ordinary hot rolled steel bars are made up of HRB and the minimum yield point of the brand. H, R, and B are the first letters in English for hot-rolled (Hotrolled), ribbed (Ribbed) and reinforced (Bars) three words. Hot rolled ribbed bar is divided into two levels, HRB335 (old No. 20MnSi), three HRB400 (20MnSiV, 20MnSiNb, old No. 20Mnti), four grade HRB500 three grade.

- Q: How long do steel rebars typically last?

- Steel rebars typically have a long lifespan and can last for several decades. The exact duration of their lifespan depends on various factors, such as the quality of the rebar, the environmental conditions it is exposed to, and the maintenance practices implemented. Generally, steel rebars are designed to be resistant to corrosion, which is one of the main factors that can affect their longevity. However, over time, rebars may experience some corrosion due to exposure to moisture, chemicals, or other corrosive agents. This can potentially reduce their lifespan. Regular inspections, maintenance, and the application of protective coatings can help extend the lifespan of steel rebars. With proper care, steel rebars can typically last 30 to 50 years or even longer.

- Q: Are steel rebars suitable for use in industrial structures?

- Yes, steel rebars are commonly used in industrial structures due to their high strength and durability. They provide reinforcement and structural support, making them suitable for withstanding heavy loads and maintaining the integrity of the structure.

- Q: Can steel rebars be used in earthquake-resistant construction?

- Yes, steel rebars can be used in earthquake-resistant construction. Steel rebars are commonly used in reinforced concrete structures to increase their strength and durability, making them better able to withstand seismic forces during an earthquake. The use of steel rebars helps to distribute the energy generated by the earthquake, reducing the risk of structural failure and enhancing the overall resilience of the building.

- Q: What is thread steel for?

- Three rebar is the new standard name for HRB400 steel, three steel for the old, as a kind of hot rolled ribbed bar. In construction, three - grade rebar is called the past.

- Q: What is the role of steel rebars in foundation slabs?

- Steel rebars play a crucial role in foundation slabs as they provide reinforcement and strength to the concrete. The rebars are strategically placed within the slab to distribute and withstand the load and stresses that the foundation may experience. This helps prevent cracks, increase durability, and enhance the overall structural integrity of the foundation slab.

- Q: What are the guidelines for proper anchoring of steel rebars in concrete structures?

- The guidelines for proper anchoring of steel rebars in concrete structures involve several key steps. Firstly, the rebars should be placed at the correct depth within the concrete to ensure sufficient bonding and structural integrity. It is important to clean the rebars thoroughly before installation to remove any dirt or debris that may hinder the bond. Additionally, the rebars should be positioned at the appropriate spacing and secured in place using rebar chairs or supports to maintain their correct position during the concrete pouring process. Adequate concrete cover should be provided around the rebars to protect them from corrosion and fire damage. Lastly, proper curing of the concrete is essential to allow the rebars to effectively bond and provide the necessary strength to the structure. Overall, following these guidelines ensures the reliable anchoring of steel rebars and enhances the overall durability and safety of the concrete structure.

Send your message to us

BS4449 ASTM A615 DCL Reinforcing Steel Rebar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords