Reinforcing Steel Rebar BS4449 ASTM A615 DCL

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 19000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

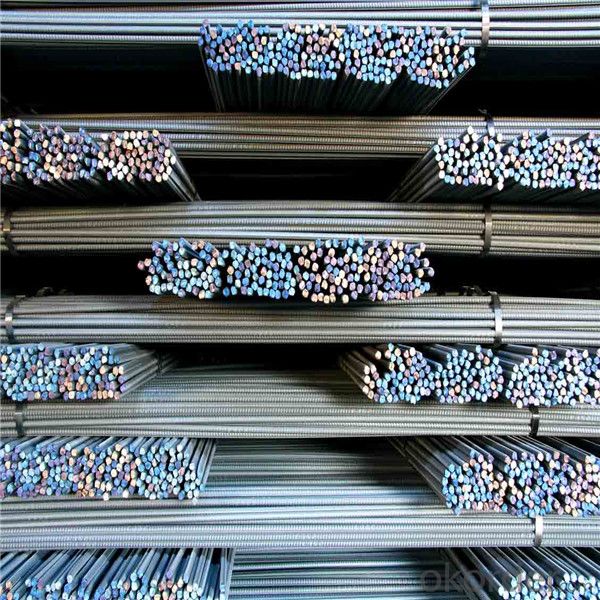

Rebar is common steel reinforcing bar, an important component of reinforced concrete and reinforced masonry structures.

It is usually formed from mild steel, and is given ridges for better frictional adhesion to the concrete.

Concrete is a material that is very strong in compression, but virtually without strength in tension. To compensate for this

imbalance in concrete's behavior, rebar is formed into it to carry the tensile loads.

Most grades of steel used in rebar cannot accept welding; such as, to adjacent steel plates or as means to bind single pieces of rebar together. However, special grades of rebar steel and welding rods make welding by expert welders possible.

To prevent workers from accidentally impaling themselves, the protruding ends of steel rebar are often bent over or covered with special plastic "mushroom" caps.

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale, easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

Our service

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing consistently high standards

of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our key markets. To maintain

our position as market leader we must continue to add value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: What is the role of steel rebars in preventing cracks in concrete?

- The role of steel rebars in preventing cracks in concrete is to provide reinforcement and strength to the structure. As concrete is strong in compression but weak in tension, the addition of steel rebars helps to distribute the tensile forces and resist cracking. The rebars act as a framework within the concrete, absorbing and dispersing the tension caused by external forces, such as loads or temperature changes. This reinforcement helps to increase the overall durability and structural integrity of the concrete, reducing the likelihood of cracks forming and ensuring the longevity of the construction.

- Q: How do steel rebars affect the overall stability of concrete structures?

- Steel rebars play a crucial role in enhancing the overall stability of concrete structures. The addition of steel rebars to concrete significantly increases its tensile strength, which is a property that concrete inherently lacks. Concrete is excellent in resisting compressive forces but weak in resisting tensile forces. By incorporating steel rebars into the concrete, the structure becomes more durable and resistant to cracking and deformation. The rebars act as reinforcement by absorbing the tensile stresses that occur due to external loads or internal forces. When these forces are applied, the concrete transfers the tensile stress to the rebars, allowing them to bear the load. This prevents the concrete from cracking and failing under tension, as the rebars strengthen the structure and distribute the forces more evenly. Moreover, steel rebars provide stability and structural integrity to concrete structures in the event of earthquakes or other natural disasters. The rebars help to resist the lateral forces that occur during seismic events, preventing the structure from collapsing or undergoing significant damage. This is particularly important in high-rise buildings or structures that are subjected to heavy loads, where the presence of rebars ensures the overall stability and safety of the structure. Additionally, steel rebars can improve the durability and longevity of concrete structures. By inhibiting cracking and reducing the potential for corrosion, the rebars protect the concrete from environmental factors such as moisture, chemicals, and temperature fluctuations. This helps to maintain the integrity of the structure over time and reduces the need for frequent repairs or replacements. In summary, steel rebars play a vital role in enhancing the overall stability of concrete structures. They provide the necessary tensile strength that concrete lacks, allowing it to withstand external loads and internal forces without cracking or failing. The presence of rebars also ensures structural integrity during seismic events and improves the durability of the concrete. Overall, steel rebars are essential components in constructing strong, safe, and long-lasting concrete structures.

- Q: Can steel rebars be used in high-strength concrete?

- Yes, steel rebars can be used in high-strength concrete. In fact, steel rebars are commonly used to reinforce concrete structures, regardless of the concrete strength. High-strength concrete refers to concrete that has a compressive strength significantly higher than conventional concrete. It typically has a compressive strength of 6,000 psi (pounds per square inch) or more. Steel rebars are essential in high-strength concrete to provide the necessary tensile strength. While concrete has excellent compressive strength, it is relatively weak in tension. By incorporating steel rebars into the concrete, the composite material becomes stronger and more durable. The rebars act as reinforcement, resisting the tensile forces and preventing cracks or failure in the structure. However, it is important to note that the selection of the appropriate steel rebar for high-strength concrete is crucial. The rebars used should have sufficient strength and ductility to withstand the higher stresses and strains associated with high-strength concrete. Additionally, proper placement, spacing, and anchorage of the rebars are essential to ensure effective reinforcement and optimal performance of the concrete structure. In summary, steel rebars can definitely be used in high-strength concrete to enhance its tensile strength and overall structural integrity.

- Q: What are the factors to consider when choosing the right steel rebar for a project?

- When selecting the appropriate steel rebar for a project, several factors need to be taken into consideration. These factors include the type of project, the structural requirements, the environment, and the specific characteristics of the rebar. One of the key factors to consider is the type of project. Different projects, such as residential buildings, bridges, or highways, have varying structural requirements. The steel rebar selected should be able to withstand the anticipated loads and stresses of the project. Additionally, the size and shape of the rebar should also align with the project's design and specifications. Structural requirements play a vital role in choosing the right steel rebar. This includes considering the required tensile strength, yield strength, and elongation properties. It is crucial to select a rebar that can provide the necessary strength and durability to ensure the structural integrity of the project. The environment in which the project will be located is another significant factor. If the project is exposed to corrosive elements, such as saltwater or chemicals, it is important to choose a rebar with corrosion-resistant properties. This can prevent premature deterioration and maintain the longevity of the structure. Furthermore, the specific characteristics of the rebar need to be evaluated. This includes the grade of the steel, which determines its strength and ductility. Different grades, such as ASTM A615 or ASTM A706, have distinct properties that suit various applications. The surface finish of the rebar, such as plain or deformed, also affects its bonding ability with concrete. Other factors that should be taken into account include the availability and cost of the steel rebar. It is crucial to ensure that the selected rebar is readily available and can be obtained in the required quantities and sizes. Additionally, the cost of the rebar should align with the project's budget constraints. In conclusion, when choosing the right steel rebar for a project, it is essential to consider factors such as the type of project, structural requirements, environmental conditions, and specific characteristics of the rebar. By carefully considering these factors, one can select the most suitable steel rebar that ensures the durability and longevity of the structure.

- Q: Can steel rebars be used in parking structures?

- Yes, steel rebars can be used in parking structures. Steel rebars are commonly used as reinforcement in concrete structures, including parking structures, to provide added strength and durability. They help to increase the load-bearing capacity and resistance to cracking or bending, making them suitable for use in parking structures where heavy vehicles and constant traffic are expected.

- Q: Are steel rebars suitable for use in industrial facilities?

- Yes, steel rebars are highly suitable for use in industrial facilities. Steel rebars are commonly used in construction projects to reinforce concrete structures, and their robustness and strength make them ideal for industrial facilities where heavy loads and high-stress environments are common. The use of steel rebars helps enhance the structural integrity and load-bearing capacity of the facility, ensuring it can withstand the demands of industrial operations. Additionally, steel rebars are highly resistant to corrosion, which is a crucial factor in industrial settings where exposure to moisture, chemicals, and other corrosive substances is prevalent. Overall, steel rebars provide the necessary strength, durability, and corrosion resistance required for industrial facilities, making them a suitable choice for reinforcing concrete structures in such environments.

- Q: What are the guidelines for protecting steel rebars during concrete pouring?

- To ensure the durability and strength of reinforced concrete structures, it is crucial to prioritize the protection of steel rebars during the concrete pouring process. The following guidelines should be adhered to: 1. Thoroughly clean the rebars prior to concrete pouring in order to eliminate any dirt, rust, or contaminants. This can be accomplished by using wire brushes or power tools to achieve a clean and smooth surface. 2. After cleaning, apply a suitable rust inhibitor or anti-corrosion coating to the rebars. This will provide protection against corrosion caused by moisture or chemicals present in the concrete. 3. Ensure that the rebars are placed at the correct depth and spacing as indicated in the structural drawings or design codes. This will provide the necessary reinforcement and structural strength to the concrete. 4. Use appropriate supports, such as chairs or spacer blocks, to maintain the correct alignment and position of the rebars during the concrete pour. This will prevent any displacement or movement of the rebars. 5. Securely tie the rebars together at intersections and overlap areas using steel wire or rebar ties. This will ensure that the rebars remain in place and maintain the desired structural configuration. 6. Prevent direct contact between the rebars and the ground during the pouring process. This can be achieved by elevating the rebars above the ground surface using plastic or concrete chairs. 7. Cover the exposed ends of the rebars with plastic caps to shield them from moisture, dirt, or other contaminants while the concrete cures. 8. Ensure that the rebars are adequately covered by the concrete. The concrete cover refers to the distance between the outer surface of the rebars and the nearest outer surface of the concrete. This cover protects the rebars from external elements and prevents corrosion. 9. Exercise caution during concrete placement to avoid displacing or damaging the rebars. Proper pouring techniques, such as utilizing a tremie pipe or a concrete pump, can help minimize the impact on the rebars. 10. After the concrete is poured, it is vital to properly cure and protect it. This involves covering the concrete with wet burlap or plastic sheeting to maintain moisture levels and prevent premature drying, cracking, or shrinkage. Adequate curing will also assist in protecting the rebars from corrosion. By adhering to these guidelines, effective protection of the rebars during concrete pouring can be achieved, guaranteeing the durability and strength of the reinforced concrete structure.

- Q: What are the common manufacturing processes for steel rebars?

- Steel rebars are manufactured through a series of steps to guarantee the production of durable and high-quality reinforcement bars. These steps usually consist of the following: 1. Melting: Initially, raw materials such as iron ore, coal, and limestone are melted in a blast furnace. This process yields molten iron, which is further refined to eliminate impurities. 2. Casting: Subsequently, the refined molten iron is poured into molds, creating large billets or blooms. These molds, commonly known as continuous casting machines, solidify the molten iron into a rectangular form. 3. Rolling: The solidified billets or blooms are then heated and passed through rolling mills. Through this rolling process, the steel is compressed between a series of rollers, reducing its thickness and shaping it into the desired dimensions of rebars. Additionally, this process enhances the mechanical properties of the steel while eliminating any internal defects or impurities. 4. Quenching and Tempering: Following the initial rolling, the rebars may undergo quenching and tempering. Quenching involves rapidly cooling the steel bars by immersing them in water or oil. This step increases the hardness of the rebars, making them more resistant to deformation and wear. Subsequently, tempering involves reheating the quenched bars to a specific temperature and gradually cooling them. This process eliminates internal stresses and improves the toughness of the rebars. 5. Cutting and Coiling: Once the rebars have been rolled and heat-treated, they are cut to the desired lengths using cutting machines. The cut rebars are then either coiled into bundles or stacked for storage and transportation. 6. Surface Treatment: Manufacturers often apply a protective coating or surface treatment to enhance the corrosion resistance of rebars. This can be achieved through hot-dip galvanizing, where the rebars are immersed in molten zinc to form a zinc coating, or epoxy coating, where a layer of epoxy resin is applied to the rebars. It is crucial to note that these manufacturing processes may vary depending on the specific requirements and standards set by different countries and industries. Nevertheless, the aforementioned steps provide a general overview of the common processes involved in manufacturing steel rebars.

- Q: How do steel rebars enhance the structural integrity of a building?

- In several ways, the structural integrity of a building is enhanced by steel rebars. Firstly, they reinforce and support concrete structures, including beams, columns, and slabs, preventing cracking or collapsing under heavy loads or external forces. The high tensile strength of steel rebars enables them to bear tensile stresses that concrete alone cannot handle, guaranteeing the building's stability and durability. Furthermore, steel rebars aid in evenly distributing and transferring loads throughout the structure, reducing concentrated stress. By reinforcing critical areas prone to tension, like corners, joints, and openings, rebars prevent cracks and ensure overall stability. Steel rebars also play a vital role in improving the structure's resistance to natural disasters like earthquakes and hurricanes. The flexibility and ductility of steel allow it to absorb and dissipate energy during seismic events or high winds, minimizing the risk of structural failure. This increased resilience ensures occupant safety and protects the building from severe damage. Additionally, steel rebars offer long-term durability by shielding the structure against corrosion. Unlike other construction materials, steel is highly resistant to degradation caused by environmental factors like moisture, chemicals, and temperature fluctuations. Corrosion-resistant rebars or protective coatings can significantly extend the building's lifespan. In conclusion, steel rebars are crucial components for reinforcing concrete structures, strengthening their integrity, stability, and resilience. By providing additional support and resistance to various stresses and loads, they contribute to the overall structural integrity of a building, guaranteeing its safety, longevity, and ability to withstand adverse conditions.

- Q: What is the recommended maximum length of cantilevered steel rebars?

- The recommended maximum length of cantilevered steel rebars depends on several factors, including the specific application, load requirements, and design codes. It is essential to consult with structural engineers and adhere to the relevant building standards and regulations to determine the appropriate maximum length for cantilevered steel rebars in a given project.

Send your message to us

Reinforcing Steel Rebar BS4449 ASTM A615 DCL

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 19000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords