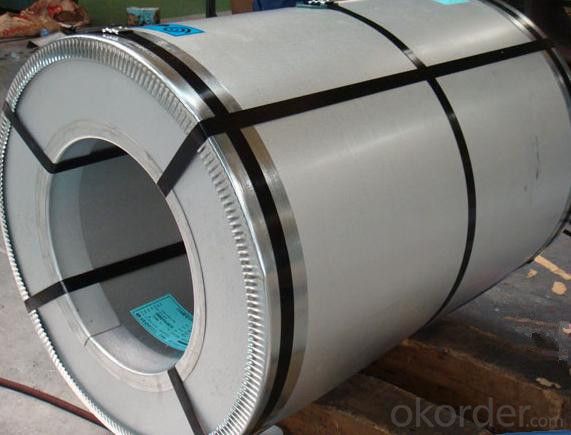

High Tensile Regular Spangle Galvanized Steel for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Basic Info.

Model NO.:SGCC, DX51D, ASTMA653

Standard:ASTM, JIS, GB, AISI, DIN, BS

Steel Grade:SGCC, Dx51d

Surface Treatment:Galvanized

Technique:Cold Rolled

Thickness:0.15-5.0mm

Width:914, 925, 1000, 1219, 1220, 1250, 1500

Zinc Coating:Z60-Z275, G30-G90

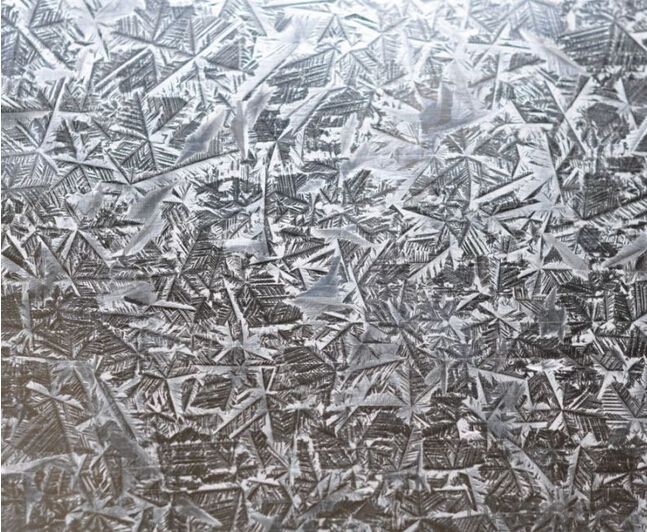

Surface:Regular Spangle, No-Spangle or Mini Spangle

Reference Standard:JIS G3302-1998, En10142-2000, GB/T2518-2004, ASTM

Export Markets:Global

Additional Info.

Packing:Export Standard

Standard:SGCC, DX51D, ASTMA653

Origin:China

HS Code:7210490000

Production Capacity:20000mt Per Month

Product Description

Products Key words:

galvanized steel, galvanized steel coil, galvanized steel sheet, gi, gi coil, gi sheet, hdgi, hot dip galvanized steel coil, galvanized sheet, gi sheet price, zinc sheets, galvanized sheet metal prices, zincked sheet, galvanized strip, price of zinc sheets, zinc strip sheet, galvanized sheet metal fence panel,corrugated galvanized steel sheet,galvanized roofing sheet

Material brand:

SGCC,DX51D,ASTMA653,commercial quality,cs type A,locking forming type,S250,S280GD,S350GD,G550,SGC400,SGC440,S250GD,S350GD,G550,SGH340,SGH440.

HDGI Manufacture

THICKNESS 0.15-5.0MM,WIDTH,914,925,1000,1219,1220,1250,1500, Galvanized steel coil, HDGI

Thick: 0.15 to 5.0mm

Reference standard: JIS G3302-1998, EN10142-2000, GB/T2518-2004, ASTM A653M

Zinc coating:Z60-Z275,G30-G90,

Regular Spangle, No-spangle or Mini Spangle

Coil diameter: ID 508mm 610mm

HDGI MECHANICAL SPECS:

JIS G3302Yield Point Minimum N/mm2Tensile Strength MinimumElongation Minimum %Application

Classified symbolN/mm2Nominal Thickness mm (t)

cold-rolled base metalhot-rolled base metal 0.25≤0.4≤0.6≤1.0≤1.6≤t≥2.5

t<0.4t<0.6t<1.0t<1.6t<2.5< span="">

SGCCSGHC205270------------------Commercial

SGCH---------------------------Commercial Hard

SGCD1------270---34363738---Drawing

SGC340SGH340245340202020202020Structural

SGC400SGH400295400181818181818Structural

SGC440SGH440335440181818181818Structural

SGC490SGH490365490161616161616Structural

---SGH540400540161616Structural

SGC570560570------------------Structural

Equal coating thickness:

Coating Weight Marking Code (Zinc)Z06Z08Z10Z12Z18Z20Z22Z25Z275

Coating Thickness0.0130.0170.0210.0260.0340.0400.0430.0490.054

Packaging Details:

Packing: Standard export packing, 4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal and waterproof paper wall protection disk, galvanized metal and waterproof paper around circumference and bore protection

Scope of Application:

Usage: construction,the manufacturing of cars, ships, containers and household electric appliances,other industries usage.

World wide customer satisfaction:

More than 50 worldwide customers none-risky experiences approved.

Yogic has been exporting steel coils to more than 50 countries directly. Our long term supply extends to USA, UK, Germany, Italy, Spain, Belgium, France, Poland, Greece, Ukraine, Belarus, Russia, Turkey, Egypt, Saudi Arabia, Iran, Ethiopia, Niger, Brazil, Colombia, Chile, Peru, Australia, New Zealand, etc

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: What are they worth today? As well as a 1943 steel nickel?

- The article I am inclosing quotes the price at 50 cents, apparently the 1943 copper penny is worth thousands of dollars.

- Q: so what is stronger tempered steel Blade or carbon steel Blade? a Machete made of those i said above what will last longer,what can cut better,which will will shatter first.

- 1. all steel blades are tempered, whether they are high carbon blades or low carbon blades. 2. It depends on what kind of steel they are made from. So im going to answer this question, using the following qualifications. 440A stainless steel 440C stainless steel - high carbon. The higher the carbon level, the more brittle a blade becomes. But the higher the carbon level, will increase a steel’s wear resistance , meaning it will have a better edge retention 2. They both will work well. Pros's / Con's The 440C blades will need less sharpening, but are harder to sharpen The 4401 blades will need to be sharpened more, but are far easier to resharpen. So it basically comes down to where you will be using them and how you will be using them. If your gonna be out in the middle of the jungle and stopping for the night, then the high carbon blade would probably be better, you use it all day, resharpen it at night. If your gonna be cutting brush, tobbaco, etc on your land, then the 440A would be better, because you can take a couple of min's to resharpen it often

- Q: Brass as a rule I believe is betterhowever I do not plan to get into reloading any time soon I just want some cheap practice ammo so will steel case ammo hurt my gun (semi auto) any more than brass ammo and if so how much more?

- I think you answered the question correctly yourself. Yes. BRASS CASE IS BETTER. MUCH MUCH BETTER. Steel case is for the birds. Brass case feeds better in semi-autos as far as I can remember. High end guns all the way to cheapo's, the brass stuff is better. Ever notice how steel case cartridges almost always seem to have visible bulges in the cases right at the butt ends of the bullets? ? ? Not quite so with brass ammo. Cheap shots or expensive shots I prefer ammo in brass.

- Q: What are the common methods of forming steel coils?

- The common methods of forming steel coils include hot rolling, cold rolling, and strip casting.

- Q: What is the typical size and weight of a steel coil?

- The typical size and weight of a steel coil can vary depending on its intended use and industry standards. However, a common size for a steel coil is around 36 inches in width and weighs approximately 5 to 10 tons.

- Q: How are steel coils used in the food processing industry?

- Steel coils are commonly used in the food processing industry for various purposes such as storage, transportation, and cooking. They are often used to create food storage containers, tanks, and silos, ensuring a safe and hygienic environment for storing raw materials or processed food. Steel coils are also used in the construction of equipment like ovens, grills, and fryers where they provide heat conductivity and durability. Additionally, steel coils are used for manufacturing conveyor belts and other machinery parts, allowing for efficient food processing and packaging operations.

- Q: my friend needs sensitive ears....she wants to borrow mine but it says surgical steel,what does that mean?

- Surgical Earrings

- Q: How are steel coils cleaned?

- Steel coils are typically cleaned using a combination of processes such as chemical cleaning, mechanical cleaning, and/or high-pressure water blasting. The specific method used depends on the type and extent of dirt or contaminants present on the coils. Chemical cleaning involves applying specialized cleaning agents to dissolve and remove dirt, oil, or other substances. Mechanical cleaning may involve scrubbing or brushing the coils to physically remove debris. High-pressure water blasting is often employed to remove tough residues or surface impurities. The cleaning process aims to ensure that the steel coils are free from any contaminants before further processing or usage.

- Q: How are steel coils stored to prevent damage?

- Steel coils are typically stored in a way that prevents damage and ensures their integrity. One common method is to stack the coils in a horizontal position. This helps distribute the weight evenly across the coils, minimizing the risk of deformation or damage. In addition, wooden or steel dunnage is often placed between each layer of coils to provide support and prevent them from shifting during storage or transportation. To further protect the coils from damage, they are often stored indoors or in covered areas to shield them from exposure to the elements. This helps prevent rusting or corrosion, which can compromise the quality of the steel. If outdoor storage is necessary, the coils may be covered with weather-resistant tarps or protective coatings to minimize the impact of rain, snow, or sunlight. Furthermore, it is important to consider the stacking height to prevent excessive pressure on the lower coils. To avoid damage, coils are typically stacked in a way that ensures the weight from the upper layers is distributed evenly across the lower ones. This can include using specialized stacking equipment or racks designed to handle the weight and dimensions of the coils. Overall, proper storage of steel coils involves careful consideration of weight distribution, protection from the elements, and minimizing contact between coils to prevent damage and maintain their quality.

- Q: How are steel coils used in the production of storage tanks?

- Steel coils are used in the production of storage tanks as they provide the necessary strength and durability required for containment and storage of various substances. These coils are rolled into cylindrical shapes and welded together to form the tank's body, ensuring a tight and secure structure. Additionally, the steel coils can be coated or treated to provide corrosion resistance, further enhancing the tank's longevity and suitability for storing liquids or gases.

Send your message to us

High Tensile Regular Spangle Galvanized Steel for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords