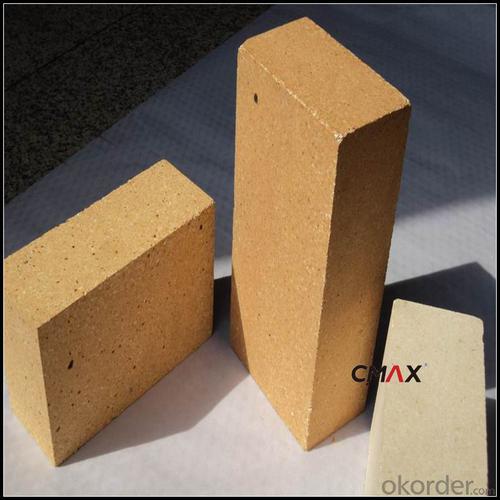

High Temperature Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Insulating Brick

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

High strength clay heat insulation refractory brick use high quality hollow drift beads and super clay as the main raw material, through high heat sintering. With the characteristics of high strength, low thermal conductivity, is suitable for industry kiln under 1350 ℃ heat insulation layer and the lining.

Insulating Brick Features

1)Excellent wear resistance

2)Good impact resistance.

3)Good corrosion resistantce.

4)Good adherence

Insulating Brick Application

1)Excellent wear resistance and long working life.

2)Good impact resistance.

3)Good corrosion resistance.

4)Good thermal shock resistance

5)High wear resistantance

6)Smooth surface and good adherence resistance.

Insulating Brick Data Sheet

Classification Temperature (℉/℃) | 3000/1650 |

Bulk Density (g/cm3 ) | ≤1.0 |

Thermal Conductivity | |

800℃, W/m.K | ≤0.39 |

1000℃, W/m.K | ≤0.43 |

1200℃, W/m.K | ≤0.48 |

Reheating Linear Change (%) | 1550℃×12h |

≤0.9 | |

Chemical Composition (%) | |

Al2O3 | ≥75 |

Fe2O3 | ≤0.5 |

Packaging & Shipping

Packaging Details:Be packed in fumigated wooden pallets

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research, development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection, supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Sales Network

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc. If any question, please contact us freely.

- Q: Are insulating fire bricks resistant to vibration or seismic activity?

- Yes, insulating fire bricks are typically resistant to vibration or seismic activity. They are designed to withstand high temperatures and provide insulation, which also makes them relatively stable and resistant to external forces such as vibrations or seismic activity.

- Q: Do insulating fire bricks require a specific curing or drying process before use?

- Insulating fire bricks typically necessitate a distinct curing or drying procedure prior to utilization. This action eradicates any moisture or volatile organic compounds (VOCs) that could be within the bricks and guarantees they attain their utmost insulating capabilities. The curing or drying procedure for insulating fire bricks generally entails a gradual increase in temperature, allowing the release of any moisture or VOCs without causing cracks or damage to the bricks. The rate of temperature escalation and the overall duration of the curing process may differ based on the bricks' type and thickness. Adhering to the manufacturer's instructions and recommendations for the specific type of insulating fire bricks employed is crucial. This ensures that the curing or drying process is executed accurately, preparing the bricks for use in high-temperature applications like kilns, furnaces, or fireplaces. Failing to appropriately cure or dry the bricks may lead to diminished insulating properties, as well as potential cracks or failure when subjected to elevated temperatures.

- Q: Can insulating fire bricks be used for both residential and commercial purposes?

- Insulating fire bricks have the capability to serve both residential and commercial purposes. Their design is specifically intended to offer superior insulation and thermal protection, which makes them highly suitable for various applications. In residential environments, these bricks can be utilized to insulate fireplaces, wood-burning stoves, and even pizza ovens, among other possibilities. In commercial contexts, they are widely employed for kilns, furnaces, boilers, and industrial ovens. The widespread applicability of insulating fire bricks contributes to their popularity as a preferred option for projects that demand efficient thermal insulation, regardless of whether they are residential or commercial in nature.

- Q: Are insulating fire bricks suitable for insulation in cryogenic applications?

- Yes, insulating fire bricks are suitable for insulation in cryogenic applications. Insulating fire bricks have excellent thermal insulation properties, low thermal conductivity, and can withstand extremely low temperatures. This makes them ideal for use in cryogenic applications where insulation is required to maintain the low temperature of the system.

- Q: Is it possible to recycle used insulating fire bricks?

- Yes, it is possible to recycle used insulating fire bricks. These bricks can be crushed, ground, or shredded, and then the resulting material can be used as a raw material in the production of new bricks or as an aggregate in construction materials. Recycling used insulating fire bricks helps to reduce waste and conserve resources.

- Q: Are insulating fire bricks resistant to chlorine gas?

- Generally, insulating fire bricks possess resistance to chlorine gas. These bricks are composed of refractory materials that are formulated to endure high temperatures and combat chemical corrosion. As chlorine gas is highly reactive, it has the potential to corrode or harm various materials. However, insulating fire bricks exhibit a strong resistance to chemical attack, thereby making them appropriate for situations where exposure to chlorine gas is likely. It should be noted that the composition and quality of these bricks may differ, hence it is advisable to consult the manufacturer or supplier for precise details regarding their resistance to chlorine gas.

- Q: Are insulating fire bricks suitable for use in the construction of drying ovens?

- Yes, insulating fire bricks are suitable for use in the construction of drying ovens. They have excellent thermal insulation properties, which helps to retain heat and prevent heat loss during the drying process. Additionally, insulating fire bricks can withstand high temperatures and have good resistance to thermal shocks, making them a reliable choice for drying oven construction.

- Q: Can insulating fire bricks be used in high-temperature ducts?

- Insulating fire bricks can indeed be used in high-temperature ducts. These bricks are specially designed to withstand extreme temperatures, making them an ideal choice for applications where heat retention and insulation are crucial. With their low thermal conductivity and high resistance to thermal shock, insulating fire bricks can effectively trap heat within the ducts, preventing any loss of energy and ensuring efficient heat transfer. Additionally, their lightweight nature makes them easy to install and handle, while their durability allows them to withstand the harsh conditions of high-temperature environments. Overall, insulating fire bricks are a reliable and effective solution for insulating high-temperature ducts.

- Q: What are the different sizes and shapes available for insulating fire bricks?

- Insulating fire bricks come in various sizes and shapes to cater to different applications and requirements. The sizes of insulating fire bricks typically range from standard sizes like 9" x 4.5" x 2.5" (commonly referred to as "9-inch bricks") to smaller sizes like 9" x 4.5" x 1". These standard sizes are widely used in the construction of fireplaces, kilns, furnaces, and other high-temperature applications. In addition to standard sizes, insulating fire bricks are also available in custom sizes, allowing for greater flexibility in design and construction. These custom sizes can vary depending on the manufacturer, but they generally follow the same width and length measurements as the standard bricks. Regarding the shape, insulating fire bricks are commonly rectangular or square-shaped. The rectangular shape is the most common and versatile, allowing for easy installation and arrangement in various structures. Square-shaped bricks are also available but may be less commonly used. It's worth noting that insulating fire bricks can be further categorized based on their density or insulation value. These bricks are typically classified into three categories: low-density, medium-density, and high-density. Each category has different insulating properties, with low-density bricks offering the highest insulation value. Overall, the wide range of sizes and shapes available for insulating fire bricks allows for customization and adaptability to different construction projects, ensuring optimal insulation and heat retention in high-temperature applications.

- Q: Are insulating fire bricks environmentally friendly?

- To a certain degree, insulating fire bricks can be deemed environmentally friendly. These bricks are crafted from abundant and readily accessible natural materials like clay, shale, and other minerals. Consequently, they do not contribute to the depletion of our natural resources. Furthermore, insulating fire bricks are engineered to possess low thermal conductivity, which aids in diminishing energy consumption. By utilizing these bricks, buildings can achieve better insulation, resulting in reduced heating and cooling requirements and, subsequently, decreased greenhouse gas emissions. Nevertheless, the manufacturing process of insulating fire bricks does have some environmental repercussions. The firing process necessitates high temperatures, which can lead to air pollution and greenhouse gas emissions. Additionally, extracting the raw materials for these bricks may cause some environmental disturbances. To truly assess the environmental friendliness of insulating fire bricks, it is vital to take into account the entire life cycle, encompassing raw material extraction, manufacturing, transportation, and disposal. Furthermore, comparing them to alternative insulation materials can offer a more comprehensive perspective on their environmental impact. In conclusion, while insulating fire bricks possess certain eco-friendly qualities such as being made from natural materials and reducing energy consumption, their overall environmental impact should be assessed holistically.

Send your message to us

High Temperature Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords