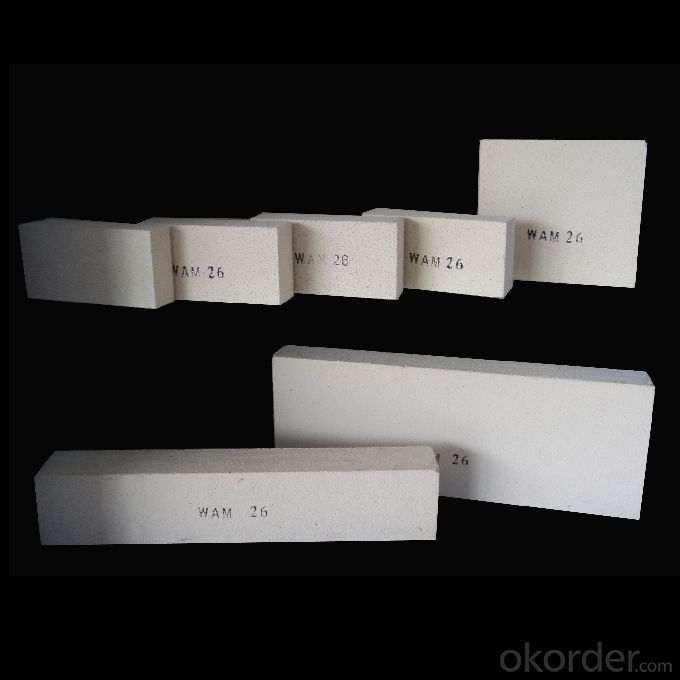

Insulation Fire Brick, Mullite Brick,Light Weight Refractory Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Insulation Fire Brick, Mullite Brick,Light Weight Refractory Brick

| Place of Origin: | (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | 30% | Al2O3 Content (%): | 50% | MgO Content (%): | 0.1% |

| CaO Content (%): | 0.1% | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | 0.1% |

| SiC Content (%): | 0.1% | Model Number: | JM-23 | Brand Name: | |

| color: | yellow white |

Packaging & Delivery

| Packaging Detail: | wooden pallet |

| Delivery Detail: | within 20 days |

Specifications

refractory mullite brick

1. Low density

2. High purity

3. Low thermal conductivity

4. Excellent thermal shock resistanc

Product Description for Insulation Fire Brick, Mullite Brick,Light Weight Refractory Brick

ADVANTAGES:

Light weight and low thermal conductivity allows thinner furnace walls

Maintain stable structural strength throughout ambient to maximum service temperature

Low heat storage results in rapid cooling and heating operation

Low iron and impurities to enhance reducing atmosphere

High thermal shock resistance in preventing spalling

Non standard sizes and shapes are available upon request

Product Uses

APPLICATION:

· Furnace repair

· Furnace, kiln, reformer and boiler linings

· Furnace door linings and seals

· Reusable insulation for steam and gas turbines

· High temperature insulation for kiln and furnace

· Primary reformer heater insulation

· High temperature insulation gaskets

· Expansion joint seals

· Glass furnace crown insulation

· Field steam generator lining

· Nuclear insulation applications

· Thermal reactor insulation

· Flexible high temperature pipe insulation

· Investment casting mold wrapping

· Removable casting mold wrapping

· Removable insulating blankets for stress relieving welds

· Pressure and cryogenic vessel fire protection

· Soaking pit seals

· High temperature filtration

· Incineration equipment and stack linings

· Petrochemical process heater fiber lining

· Heat treating furnace or intermittent (shuttle) kiln lining

· General furnace backup insulation

· Heat seals for kiln car or furnace door

· Electrical insulator

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What other products does OKorder offer?

A3: We offer a full range of refractory bricks, mortar, cement, ceramic fiber products, and more.

- Q: Can insulating fire bricks be used in the construction of smelter crucibles?

- Insulating fire bricks are indeed suitable for constructing smelter crucibles. These bricks are composed of high-temperature-resistant materials, which make them ideal for smelting tasks. Their low thermal conductivity aids in preserving heat and preventing excessive heat loss from the crucible. Consequently, insulating fire bricks are perfect for creating a well-insulated and efficient crucible that can endure the intense heat and thermal shock involved in smelting processes. Furthermore, these bricks are lightweight and easily malleable, enabling convenient construction and customization of the crucible's design. Ultimately, incorporating insulating fire bricks in smelter crucible construction enhances thermal efficiency and durability, resulting in more effective and productive smelting operations.

- Q: Can insulating fire bricks be used in boilers for residential heating?

- Yes, insulating fire bricks can be used in boilers for residential heating. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation properties. These bricks are commonly used in the construction of boilers and furnaces due to their ability to retain heat and prevent heat loss. They can help improve the energy efficiency of the boiler system by reducing heat transfer to the surroundings, allowing for more efficient heating and lower energy consumption. Additionally, insulating fire bricks are durable and resistant to thermal shock, making them suitable for the high temperatures and rapid temperature changes commonly experienced in boilers. Therefore, using insulating fire bricks in residential heating boilers can help improve their performance and energy efficiency.

- Q: Is the quality of brick made of small-sized self insulation block equipment the same as that of large block brick equipment?

- Recently, a lot of people have encountered this problem, Silver Horse understand, in fact, the brick machine is only the production of different production, the quality of the bricks produced are the same.

- Q: Are insulating fire bricks suitable for insulation in walls?

- Typically, insulating fire bricks are unsuitable for wall insulation. Although they excel in high-temperature settings, like furnaces or kilns, their insulation capabilities for walls are limited. Insulating fire bricks possess lower thermal conductivity than regular bricks, resulting in slower heat conduction. Nevertheless, they are not as effective as wall-specific insulation materials such as fiberglass, foam boards, or mineral wool. These materials are engineered to offer superior insulation properties, including higher R-values that measure resistance to heat transfer. Furthermore, insulating fire bricks tend to be pricier and heavier compared to other insulation options, making them less practical for wall insulation. Therefore, while insulating fire bricks do have advantages in certain applications, they are generally not the optimal choice for wall insulation.

- Q: Are insulating fire bricks resistant to spalling?

- Insulating fire bricks exhibit resistance to spalling. These bricks are specially engineered to endure elevated temperatures and thermal shock, rendering them highly immune to spalling. Spalling indicates the fracturing and fracturing of bricks owing to exposure to extreme heat. Composed of superior refractory materials with low thermal conductivity, insulating fire bricks restrict heat transmission and diminish spalling hazards. Moreover, these bricks boast a remarkable melting point, rendering them excellently suited for applications demanding high temperatures. Consequently, insulating fire bricks find widespread application in furnaces, kilns, and other environments characterized by elevated temperatures, where spalling poses a significant concern.

- Q: Are there any construction waste materials for composite thermal insulation bricks?

- Light insulation brick usually refers to hollow bricks, and the normal indoor partitions are made of such bricks, which can not increase the weight of the floor, and the sound insulation effect is good!

- Q: Can insulating fire bricks be used in boilers for steam generation?

- Boilers can utilize insulating fire bricks for steam generation. These bricks are composed of lightweight materials, such as ceramic fibers or expanded clay, that possess exceptional insulation properties. Their low thermal conductivity ensures effective heat transfer prevention. The insulation within boilers is crucial for minimizing heat loss and enhancing energy efficiency. Insulating fire bricks can be utilized to line the boiler combustion chamber's walls, roof, and floor. By creating a highly insulating barrier, they retain heat within the chamber, enabling more efficient steam generation. Additionally, insulating fire bricks possess the ability to withstand high temperatures, making them suitable for boilers that involve elevated temperature steam generation. They also exhibit resistance to thermal shock, which is significant in scenarios where temperature fluctuations can arise. In conclusion, insulating fire bricks offer considerable advantages for boiler applications. They provide exceptional insulation, can endure high temperatures, and contribute to enhanced energy efficiency in steam generation.

- Q: Are insulating fire bricks resistant to thermal shock cracking?

- Yes, insulating fire bricks are resistant to thermal shock cracking. These bricks are specifically designed to withstand high temperatures and rapid changes in temperature without cracking. They have a low thermal conductivity, which means they can effectively trap and retain heat without being damaged by thermal shock. Insulating fire bricks are often used in applications where thermal shock is a concern, such as in furnaces, kilns, and other high-temperature environments. Their resistance to thermal shock cracking makes them a reliable choice for these types of applications.

- Q: What is the typical moisture content of an insulating fire brick?

- The moisture content of an insulating fire brick can vary depending on factors such as its specific composition, the manufacturing process used, and the conditions in which it is stored. However, insulating fire bricks are typically designed to have minimal moisture content in order to enhance their insulation capabilities and resistance to thermal shock. Generally, insulating fire bricks have a moisture content ranging from 0.5% to 2%. This low moisture content is crucial in preventing the bricks from cracking or spalling when exposed to high temperatures. Additionally, it reduces the risk of damage caused by moisture, such as freeze-thaw cycles or the release of steam upon heating. To ensure the optimal performance and longevity of insulating fire bricks, it is advisable to store them in a dry environment and protect them from moisture during transportation and installation.

- Q: Can insulating fire bricks be used in high-temperature ducts?

- Yes, insulating fire bricks can be used in high-temperature ducts. Insulating fire bricks are designed to withstand high temperatures and provide thermal insulation, making them suitable for use in ducts where high temperatures are present.

Send your message to us

Insulation Fire Brick, Mullite Brick,Light Weight Refractory Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords