High Strength PP Geogrid Geocells for Erosion Control

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

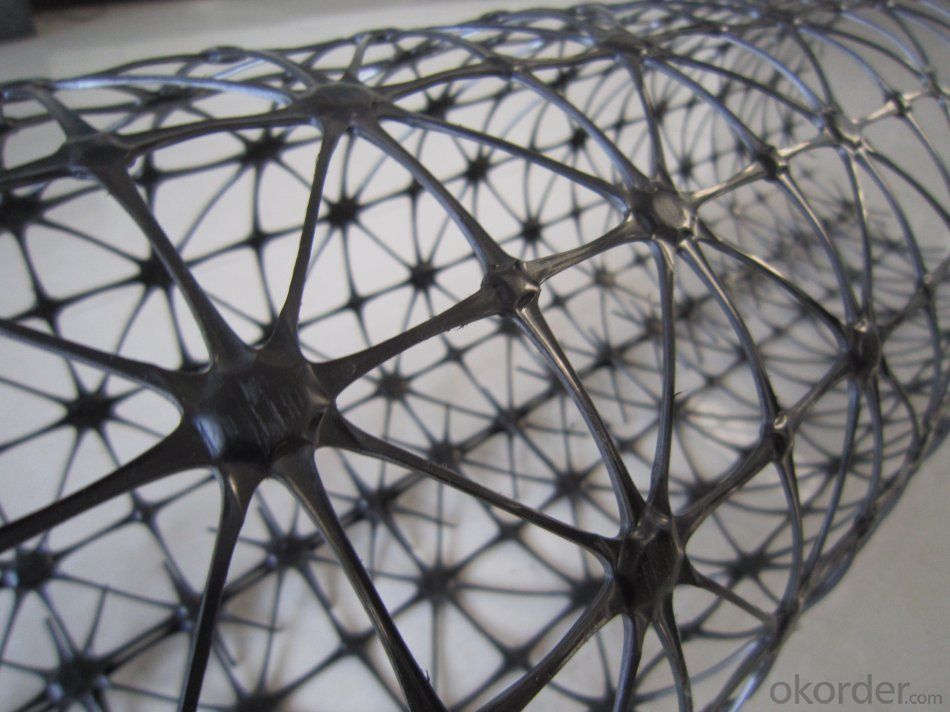

Introduction of PP/HDPE Uniaxial Geogrid:

Uniaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in the longitudinal direction.

Features of PP/HDPE Uniaxial Geogrid:

With high tensile strength and tensile modulus

Application of PP/HDPE Uniaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects, retaining wall, dam etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing area , project cost and maintenance cost.

Performance of Fiberglass Geogrid:

--- High strength, high modulus and low temperatures resistance.

Applications of Fiberglass Geogrid:

--- Reinforcement for road pavement

--- Reinforcement for railway basement

--- Reinforcement for Tunnel

--- Reinforcement for Slope

--- Reinforcement for embankment.

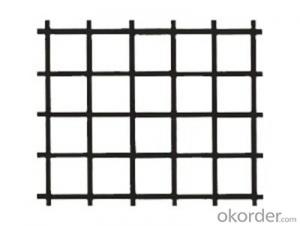

Features of PP Biaxial Geogrid:

1. With high tensile strength in longitudinal and transversedirections

2.This structure can provide an chain system of more effective force bearing and spreading for the soil.

Application of PP Biaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing project cost and maintenance cost.

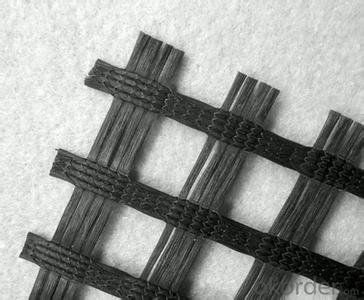

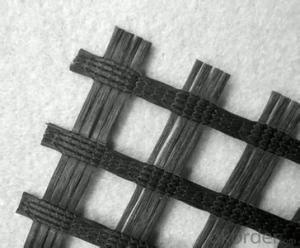

Features of Polyester Geogrid:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Application of Polyester Geogrid:

It mainly applied in strengthening soft ground of rail and road.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: PA66 plus 30% glass Shrink is how much

- PA66 plus 30% glass fiber shrinkage 0.7%--1.0%, different brands of different manufacturers of some differences.

- Q: Construction method of glass fiber grid

- At present, the commonly used glass fiber geogrid has two kinds of self adhesive and no self adhesive. The adhesive tape can be directly laid on the flat base. The materials needed for nail fixation:I. 40 x 40 x 0.3 mm of fixed iron, the requirements of flat angleIi. 2 inch steel nails (high quality cement nails)

- Q: Can geogrids be used for reinforcement in soft soils?

- Yes, geogrids can be used for reinforcement in soft soils. Geogrids are designed to provide stability and improve the load-bearing capacity of soils, including soft soils. They can be installed to distribute and restrain the forces exerted on the soil, preventing excessive settlement and improving overall performance.

- Q: Can geogrids be used in load transfer platforms?

- Yes, geogrids can be used in load transfer platforms. Geogrids are engineered materials that are commonly used in civil engineering applications to reinforce soil, provide stability, and distribute loads. In load transfer platforms, geogrids are employed to enhance the performance of the platform by spreading the load more evenly and reducing the risk of settlement or failure.

- Q: Are geogrids suitable for reinforcing contaminated soil?

- Yes, geogrids are suitable for reinforcing contaminated soil. Geogrids are designed to enhance the stability and strength of soil, regardless of its condition. They can effectively reinforce contaminated soil, providing additional support and preventing soil erosion, even in challenging environments.

- Q: Can geogrids be used in seismic zones?

- Yes, geogrids can be used in seismic zones. Geogrids are commonly used in geotechnical engineering to reinforce soils and provide stability to structures. They can also help mitigate the effects of earthquakes by distributing the seismic forces and reducing soil liquefaction. However, specific design considerations and geogrid properties should be taken into account to ensure their effectiveness in seismic zones.

- Q: Are geogrids resistant to biodegradation?

- Yes, geogrids are generally resistant to biodegradation. They are constructed using synthetic materials such as polyester or polypropylene, which have low susceptibility to biological degradation. This makes geogrids durable and suitable for long-term use in various applications, including soil stabilization and erosion control.

- Q: Can geogrids be used in wastewater treatment applications?

- Yes, geogrids can be used in wastewater treatment applications. They are commonly used to reinforce and stabilize soils in the construction of wastewater treatment plants, lagoons, and containment ponds. Geogrids offer excellent tensile strength, durability, and resistance to chemical degradation, making them suitable for these applications. They help to prevent soil erosion, maintain the stability of structures, and enhance the overall efficiency and effectiveness of wastewater treatment processes.

- Q: What are the installation guidelines for geogrids?

- The installation guidelines for geogrids typically include steps such as preparing the ground surface, ensuring proper compaction, excavating and leveling the area, placing the geogrid in the desired position, securely anchoring it, and then covering it with fill material. These guidelines may vary depending on the specific project requirements and the type of geogrid being used, so it is important to refer to the manufacturer's instructions for detailed installation procedures.

- Q: What are the models and specifications of Geogrid for road

- There are many kinds of specifications for each grid, with reference to the national standard

Send your message to us

High Strength PP Geogrid Geocells for Erosion Control

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords