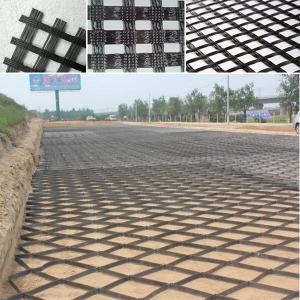

High Strength PP Biaxial Geogrid for Slope Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 150000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

CMAX Biaxial geogrid is manufactured from polypropylene. It is produced through the process of extruding, punching,

heating, longitudinal stretching and transverse stretching.

Performance:

Homogeneous structure, low creep, anti-aging and resisting acid and alkaline.

Applications:

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and

roadway in the coal mine.

Packing

FAQ

●How long have you been in international trade and geosynthetics industry?

10-year experience in international trade.

20-year experience in geosynthetics field.

●Which payment do you accept?

For you convinience,our payment can be L/C,TT,Westunion,paypal

●Can I know the width you can produce?

Of course we can,our width can be 1 to 6m

●How will you pack the products?

Usually we pack our products by woven bags,also we can do as your requirements

●We want to make sure quality,is free sample available?

We can supply free samples if you need.

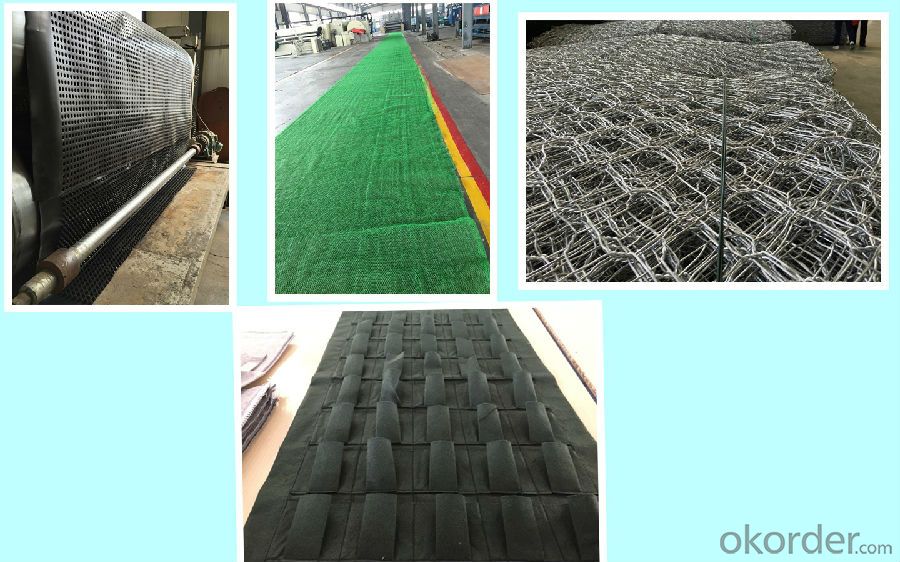

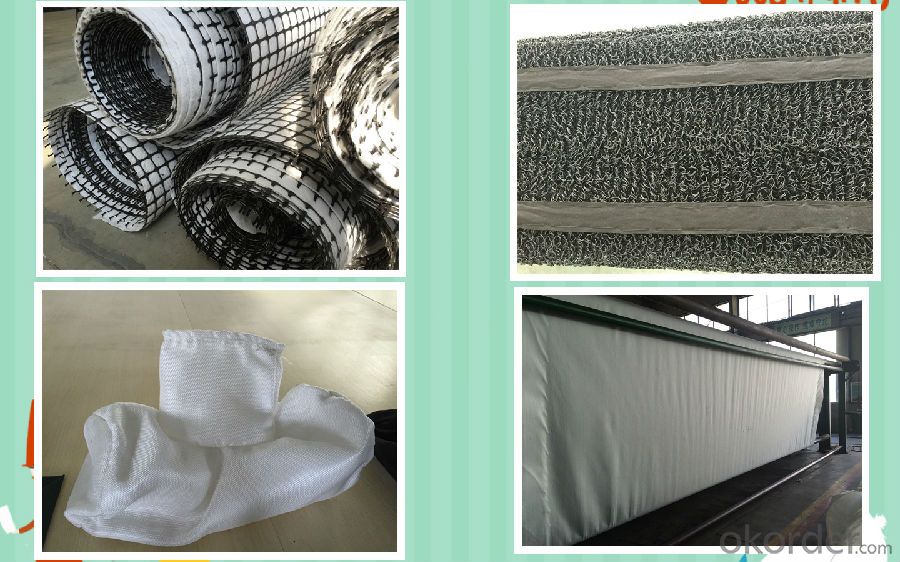

●Do you have other products?

Yes, we have, please check the pictures:

- Q: Are geogrids suitable for reinforcement of mechanically stabilized aggregate layers?

- Yes, geogrids are suitable for reinforcement of mechanically stabilized aggregate layers. Geogrids are commonly used in civil engineering to enhance the stability and load-bearing capacity of soil or aggregate layers. They provide tensile strength and distribute applied loads, reducing the potential for deformation or failure in mechanically stabilized layers.

- Q: Can geogrids be used in retaining walls for industrial facilities?

- Yes, geogrids can be used in retaining walls for industrial facilities. Geogrids are commonly used in retaining walls to increase their stability by providing soil reinforcement. They help distribute the forces exerted by the retained soil, making them suitable for use in retaining walls for industrial facilities where there may be higher loads and potentially unstable soil conditions.

- Q: How much is a glass fiber mesh

- What size, how much, these things are not the same price.

- Q: What are the types of Geogrid

- There are many types of geogrid is about tgsg / convex node tgsg / whole tgsg / glass fiber geogrid

- Q: Are geogrids suitable for use in green roof systems?

- Yes, geogrids are suitable for use in green roof systems. Geogrids provide stability and reinforcement to the roof system, preventing soil erosion and promoting the growth of vegetation. They also help distribute the weight evenly, making the green roof more structurally sound.

- Q: What are the load-bearing capacities of geogrids?

- The load-bearing capacities of geogrids vary depending on the specific type and design of the geogrid, as well as the soil conditions and application. However, geogrids are typically engineered to have high tensile strength and can support heavy loads, ranging from several hundred to several thousand kilonewtons per meter.

- Q: Geogrid is divided into several?

- Main production, geotextile, geogrid, geomembrane

- Q: What are the differences between geogrids and geosynthetic clay liners?

- Geogrids and geosynthetic clay liners (GCLs) are both geosynthetic materials used in geotechnical applications, but they have distinct differences. Geogrids are typically made from high-strength polymers, such as polypropylene or polyester, and have a grid-like structure. They are used to reinforce soil, providing tensile strength and preventing soil erosion. Geogrids are commonly used in road construction, retaining walls, and slope stabilization projects. On the other hand, geosynthetic clay liners (GCLs) consist of a layer of bentonite clay sandwiched between two geotextiles. The clay component of GCLs gives them excellent hydraulic barrier properties, making them highly effective in containment applications. GCLs are commonly used in landfills, mining sites, and other projects that require the containment of liquids or gases. In summary, while geogrids reinforce soil and provide tensile strength, geosynthetic clay liners act as hydraulic barriers and are used for containment purposes.

- Q: In the case of the subgrade with Geogrid

- When the subgrade for soft foundation treatment using geogrid, geogrid is used as reinforcement of reinforced earth structure or reinforced material, the main function is to play the role of tensile.

- Q: The geogrid is convenient for construction, time saving, labor saving, shorten the construction period and reduce maintenance cost.

- Construction method:1, wall to keep clean and dry.2, in the cracks and adhesive tape.

Send your message to us

High Strength PP Biaxial Geogrid for Slope Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 150000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords