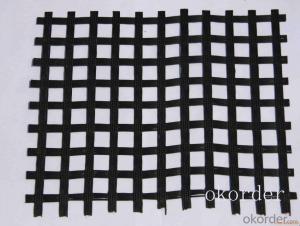

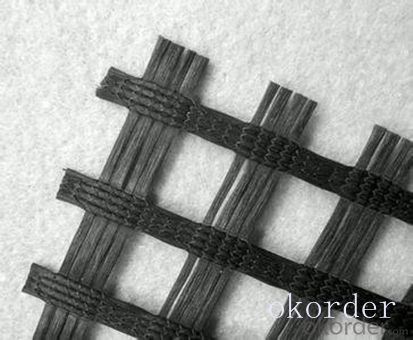

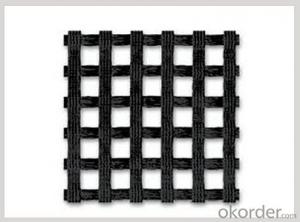

High Strength Fiberglass Geogrid Polyethylene Geotextile for Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

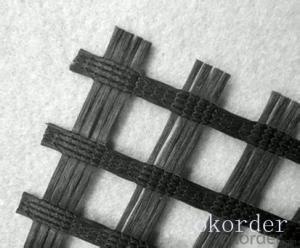

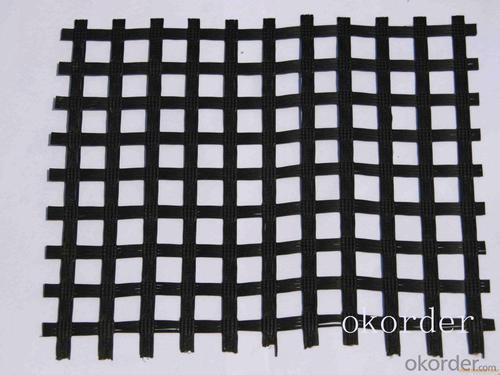

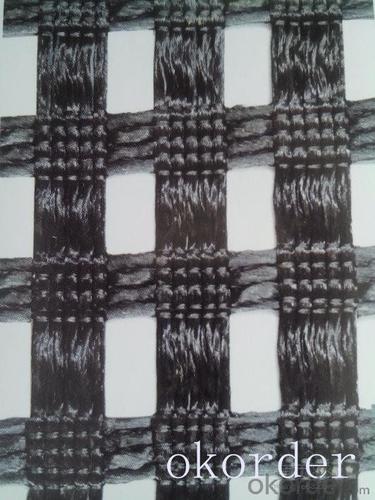

We offer a unique line of extruded polymer grids for protecting and reinforcing grassed vehicular areas. Reinforcement Mesh is a tough extruded polymer grid for reinforcing grassed areas used by vehicles and pedestrians. We are inert to biological degradation and resistant to creep, strain and naturally found chemicals.steel-plastic composite geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100KN

PP geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100,110x110KN

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles help in groundwater protection?

- Geotextiles help in groundwater protection by acting as a barrier that prevents the infiltration of pollutants into the groundwater system. They are used in various applications such as drainage systems, landfills, and erosion control, where they provide filtration and separation of soil particles, ensuring that only clean water enters the groundwater.

- Q: Can geotextiles be used in geocomposite drains?

- Yes, geotextiles can be used in geocomposite drains. Geocomposite drains typically consist of a geotextile fabric wrapped around a core material, such as a perforated pipe. The geotextile helps to filter and separate fine particles from the core material, preventing clogging and enhancing drainage efficiency.

- Q: Can geotextiles be used in coastal dune stabilization projects?

- Yes, geotextiles can be used in coastal dune stabilization projects. Geotextiles are commonly used in such projects to create barriers that help prevent erosion, promote vegetation growth, and provide stabilization to the dune system. They can effectively control sand movement, prevent sand loss, and enhance the stability and resilience of coastal dunes.

- Q: Can geotextiles be used in shoreline protection?

- Yes, geotextiles can be used in shoreline protection. They can help to stabilize soil and prevent erosion by acting as a barrier against water, while still allowing proper drainage. Geotextiles can also help to reinforce and protect shoreline structures such as retaining walls or revetments.

- Q: How to deal with the use of geotextiles under the roof

- Drainage board, geogrid

- Q: What are the different geotextile manufacturing processes?

- There are several different geotextile manufacturing processes, including needle punching, thermal bonding, and weaving.

- Q: How are geotextiles used in civil engineering?

- Geotextiles are commonly used in civil engineering for various purposes such as erosion control, soil stabilization, filtration, drainage, and reinforcement. They are often used as a protective layer to prevent soil erosion on slopes or as a barrier to separate different layers of soil. Geotextiles also help in improving soil stability by distributing loads and reducing the risk of settlement. Additionally, they play a crucial role in filtration systems by allowing water to pass through while retaining soil particles. Overall, geotextiles are versatile materials that enhance the performance and longevity of civil engineering projects.

- Q: What are the key factors affecting the puncture resistance of geotextiles?

- The key factors affecting the puncture resistance of geotextiles include the type and thickness of the geotextile material, the tensile strength of the fibers used, the density of the fabric, and the presence of any protective coatings or additives. Additionally, the installation and construction methods, as well as the conditions and properties of the underlying soil or material, can also influence the puncture resistance of geotextiles.

- Q: What is the latest price of geotextile?

- Per ton of national standard short geotextile 7000-8000 yuan, filament geotextile per ton - yuan.

- Q: Can geotextiles be used in the protection of embankments?

- Yes, geotextiles can be used in the protection of embankments. Geotextiles are commonly used as a reinforcement material to stabilize the soil and prevent erosion on embankments. They can help to improve the overall strength and stability of the embankment by increasing its resistance to water flow and reducing the potential for slope failure. Additionally, geotextiles can promote vegetation growth, further enhancing the embankment's stability and protecting it from erosion.

Send your message to us

High Strength Fiberglass Geogrid Polyethylene Geotextile for Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords