High Strength Biaxial Geogrids / PP Uniaxial Geogrid / Fiberglass Geogrid

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Fiberglass Geogrid:

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

It is characterized by high tensile strength in axial and lateral directions, low stretch rate, alkali-resistance, low temperature- resistance, as well as convenience in construction and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life.

Performance of Fiberglass Geogrid:

--- High strength, high modulus and low temperatures resistance.

Applications of Fiberglass Geogrid:

--- Reinforcement for road pavement

--- Reinforcement for railway basement

--- Reinforcement for Tunnel

--- Reinforcement for Slope

--- Reinforcement for embankment.

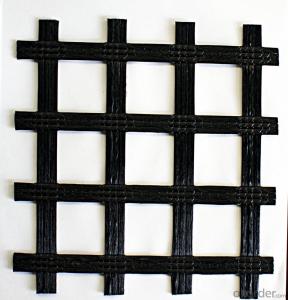

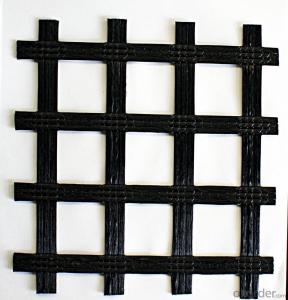

Introduction of PP Biaxial Geogrid:

Biaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in longitudinal and transverse directions.

Features of PP Biaxial Geogrid:

1. With high tensile strength in longitudinal and transversedirections

2.This structure can provide an chain system of more effective force bearing and spreading for the soil.

Application of PP Biaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing project cost and maintenance cost.

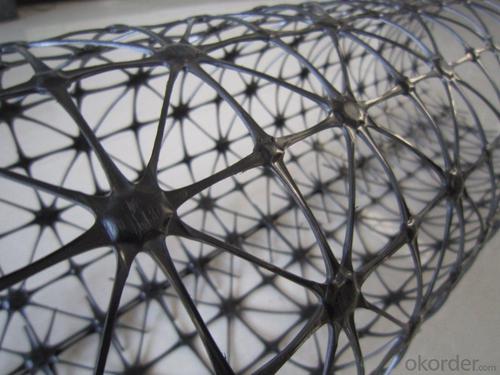

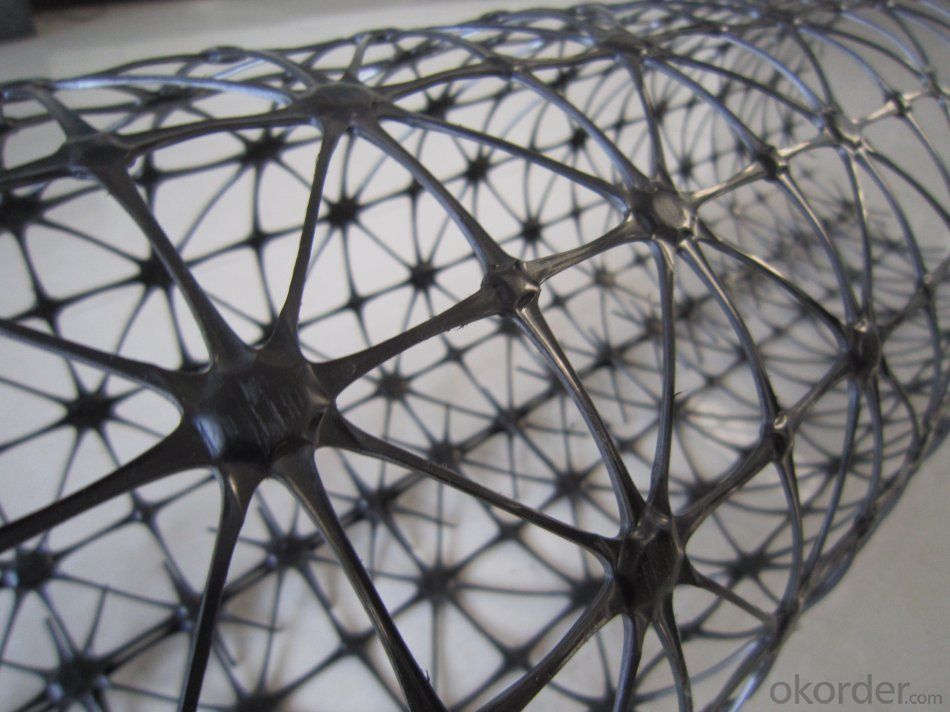

Features of Polyester Geogrid:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Application of Polyester Geogrid:

It mainly applied in strengthening soft ground of rail and road.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: How do geogrids improve the performance of geotextile containers?

- Geogrids improve the performance of geotextile containers by providing additional strength, stability, and reinforcement to the structure. By incorporating geogrids into the design, geotextile containers become more resistant to stress, deformation, and settling. The geogrids effectively distribute loads across the container's surface, preventing excessive strain on the geotextile material and maintaining the integrity of the structure.

- Q: What are the limitations of geogrids?

- Geogrids have a few limitations that need to be considered. Firstly, they are not suitable for all types of soil. They work best in cohesive soils and may not be as effective in non-cohesive or sandy soils. Secondly, geogrids have limited resistance to chemical degradation, so they may not be appropriate in environments with high chemical exposure. Lastly, geogrids are not designed to withstand heavy loads or provide significant structural support on their own, so they should be used in conjunction with other reinforcement techniques for optimal performance.

- Q: Can geogrids be used in pond liners?

- Yes, geogrids can be used in pond liners. Geogrids are commonly used in pond construction to reinforce the pond liner and provide stability to the structure. They help prevent soil erosion and enhance the longevity of the pond liner.

- Q: Can geogrids be used in reinforcement of bridge abutments on soft clays?

- Yes, geogrids can be used in the reinforcement of bridge abutments on soft clays. Geogrids are commonly used in geotechnical engineering as a soil reinforcement material. When placed in soft clay soils, they can improve the stability and strength of the soil, providing additional support to bridge abutments and preventing excessive settlement or failure. By distributing the load more evenly and increasing the bearing capacity of the soil, geogrids can effectively reinforce bridge abutments on soft clays.

- Q: Can geogrids be used in construction of temporary access roads over soft ground?

- Yes, geogrids can be used in the construction of temporary access roads over soft ground. Geogrids provide reinforcement and stabilization to the soil, distributing the load and preventing excessive settlement and rutting. This makes them an effective solution for creating temporary access roads that can withstand heavy traffic and adverse ground conditions.

- Q: How do geogrids enhance the performance of geosynthetic clay liner erosion control blankets?

- Geogrids enhance the performance of geosynthetic clay liner erosion control blankets by providing additional reinforcement and stability. They help to distribute the load and prevent the geosynthetic clay liner from shifting or sliding, thereby increasing its resistance to erosion.

- Q: Do geogrids provide reinforcement to geosynthetic clay liners in waste containment facilities?

- Yes, geogrids can provide reinforcement to geosynthetic clay liners in waste containment facilities. Geogrids are commonly used in conjunction with geosynthetic clay liners to enhance their tensile strength and prevent their displacement. This reinforcement helps to improve the overall stability and performance of waste containment facilities.

- Q: Can geogrids be used in coastal protection structures?

- Yes, geogrids can be used in coastal protection structures. Geogrids are commonly used in coastal erosion control measures, such as revetments and seawalls, to reinforce the soil and provide stability. They help improve the overall strength and resistance of the structure to wave forces and erosion, making them an effective solution for coastal protection.

- Q: What are the design considerations for geogrids in mechanically stabilized earth walls?

- Some of the key design considerations for geogrids in mechanically stabilized earth (MSE) walls include selecting the appropriate geogrid material and strength, determining the required geogrid spacing and length, considering the connection and anchorage details, assessing the interface friction between the geogrid and the soil, and evaluating the long-term durability and performance of the geogrids in the specific environmental conditions. Additionally, proper installation practices and quality control measures should be implemented to ensure the geogrids are correctly positioned and tensioned within the MSE wall system.

- Q: How do geogrids prevent differential settlement?

- Geogrids prevent differential settlement by distributing the load and enhancing the stability of soil by providing reinforcement. They improve the overall strength and stiffness of the soil, reducing the likelihood of differential settlement occurring.

Send your message to us

High Strength Biaxial Geogrids / PP Uniaxial Geogrid / Fiberglass Geogrid

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords