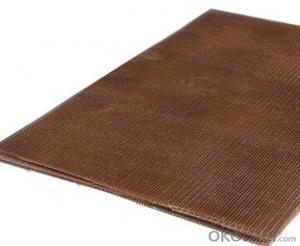

High Silica Fiberglass Mesh Ceramic Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

high silica mesh casting filter can effectively remove slag,refractory particles and non-metallic inclusions from molten metals.It is developed as a low cost but with rather filtration efficiency alternative to ceramic filters.

Made from specially treated silica yarns,silica mesh filters are capable of withstanding pouring temperatures up to 1620 Degree C.

Silica mesh filters are ideal for in-mold filtration of gray, malleable,white,compacted graphite and ductile cast irons, as well as non-ferrous aluminum and copper-based metal alloys and many types of small scale steel casting filtration.

ADVANTAGES:

• Low cost and easy to use

• Improves fluidity and metal distribution

• Removes micron sized inclusions and impurities

• Can be used with existing pattern equipment

• Eliminates inclusions created by ceramic chips

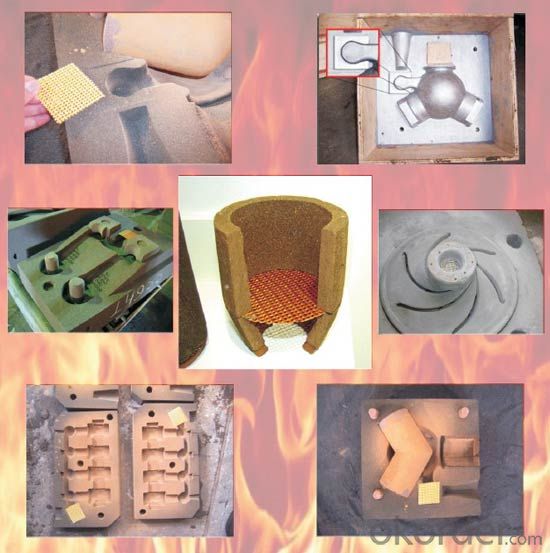

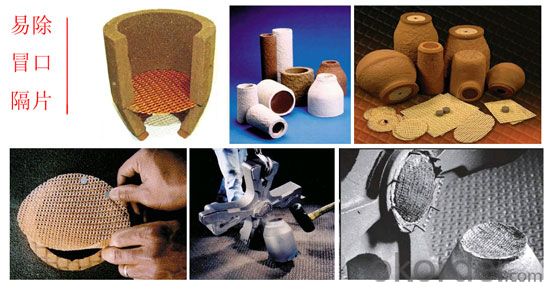

APPLICATIONS:

• Cut pieces for in mold filtration like sand casting,gravity casting,etc.

• Cut pieces for riser sleeves,bottom or across ports in walls

• Cut pieces to provide a weakened plane for riser knock-off

• Cup shapes for investment casting

SPECIFICATION:

Model No. | SiO2% | Thickness | Mesh size | Max.Temp. | Open area | Max.work time |

HSFG-15 | ≥96 | 0.35mm | 1.5x1.5mm | 1450℃ | 55% | 10minutes |

HSFG-20 | ≥96 | 0.35mm | 2.0x2.0mm | 1450℃ | 60% | 10minutes |

HSFG-25 | ≥96 | 0.35mm | 2.5x2.5mm | 1450℃ | 70% | 10minutes |

HSFG-S15 | ≥96 | 0.98mm | 1.5x1.5mm | 1620℃ | 22% | 15seconds |

HSFG-S20 | ≥96 | 0.98mm | 2.0x2.0mm | 1620℃ | 26% | 15seconds |

HSFG-S25 | ≥96 | 0.98mm | 2.5x2.5mm | 1620℃ | 32% | 15seconds |

FILTERING TIPS:

• Copper alloys&leaded bronze:1.5x1.5mm mesh

• Gray Iron:1.5x1.5mm mesh

• Ductile Iron:2.0x2.0mm &2.5x2.5mm mesh

• Small scale steel:1.5x1.5mm mesh

*Cut pieces can be rectangular or round,size from 20mm to 900mm.

*Preformed cup filter OD can be 100/110/115/120mm or as per request.

- Q: Influence factors of ceramic filter

- (1) the particle size and the distribution of the material match the microporous of the ceramic filter plate. Although the ceramic filter plate aperture is bigger, easy to suck the pulp, but easy to cause the ceramic filter board to block up.(2) the ceramic filter plate with the same ceramic filter plate with high pore permeability and high water permeability is selected with high water permeability and good slurry absorption performance. The spindle speed is slow, the formation time of growth in the area of vacuum filter cake, production capacity increased gradually, but because the unit time of grout thickness and spindle speed slow is proportional to, so the ceramic filter capacity in a range of showing the highest.

- Q: What is the filtration accuracy of 50nm ceramic membrane?

- The filtration accuracy is the maximum particle size that the membrane can pass through.

- Q: Principle of chemical engineering drum vacuum filter, the faster the speed, the less the amount of filtrate obtained per turn, the more the amount of filtrate obtained per unit time?

- In unit time, the more turns of the drum, the greater the centrifugal force, the greater the rate of filtration in unit time, that is to say, the amount of filtrate in unit time is moreRotating drum vacuum filter, the greater the speed, the greater the filtration rate, but the shorter the time each turn, the amount of each filtrate will be reduced

- Q: What is the working pressure of the ceramic filter?

- Vacuum pressure or suction is the vacuum of the equipment, the size of the vacuum directly affects the effect of ceramic filter board suction (yield and water content). The vacuum system of ceramic filter consists of vacuum pumps, tanks, distribution device, ceramic filter plate and a connecting pipe is composed of ceramic filter, the vacuum pump is generally 2BV series water circulation pump, the vacuum pump vacuum limit is -0.097MPa, using a vacuum pump for a long time or vacuum system has poor sealing performance may cause a certain degree of vacuum distortion, so the ceramic filter vacuum is generally difficult to achieve in the -0.097MPa, -0.08 ~ 0.097MPa, which indicates that the vacuum degree is good, such as the vacuum degree is not up to -0.07MPa or less, the vacuum system may be an exception.

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large

- There is a difference between the vacuum display and the actual vacuumThe main speed of the ceramic filter is too fastThe water content of the filter cake is gradually increased within 0~8 hours after the equipment has been continuously turned onThe ceramic filter plate does not meet the aperture range and the opening rate is lowThe ceramic filter plate has a near life and serious blockageCeramic filter cleaning standards (acid, ultrasonic, backwash water)The scraper can not be completely discharged, and the surface of the ceramic plate is coated with a thin filter cakeFailure to manufacture equipment or other causes of failure

- Q: Microporous ceramic filter plate cleaning

- In order to avoid the possibility of plugging, ceramic filter plates with suitable aperture range of different manufacturers can be selected.

- Q: What are the reasons for the program alarm of ceramic filter?

- The vacuum failure may be the vacuum pump failure, the vacuum pipeline leakage, the ceramic filter plate rupture or the connection water leakage, the backwash system is generally before the filtration water pressure is insufficient, the filter core plug and so on. Vacuum suction deficiency will lead to poor effect or even suction; cleaning standards will accelerate the ceramic filter clogging, ceramic filter clogging even if the vacuum suction is normal, will not even bad effect such as cake, jelly thin with high water content. Ceramic filter plate, hole plugging, discarding. Ceramic filter plate is life, under normal circumstances is about a year, such as pulp mud content, fine particle size or containing ingredients, cleaning is not easy to precipitate standards will reduce its life, when the ceramic filter plate close to the scrap, the suction effect will be worse. I hope my answer can help you.

- Q: What is the reason that the whole ceramic filter does not attract ore?

- Vacuum system failure, no vacuum or vacuum can not meet the requirements. Should check the vacuum pump and vacuum piping, distribution head, ceramic plate, such as failure or leakage.Whether the ore conditions are changed, such as pulp type, mud content, fineness, concentration, etc..

- Q: What is the backwashing pressure of the ceramic filter?

- It should be said that the ceramic filter backwash, usually with a certain pressure of clean water to backwash.

- Q: How to determine the quality of ceramic fiber filter board simply?

- Ceramic fiber board quality can be judged from the following aspects:1, appearance. The surface is flat and the cutting surface is well arranged, and vice versa.2 density. Press the hands, and the surface is soft and smooth.3, process. Vacuum suction and continuous production process.4, cross section, slag ball content is low.

Send your message to us

High Silica Fiberglass Mesh Ceramic Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords