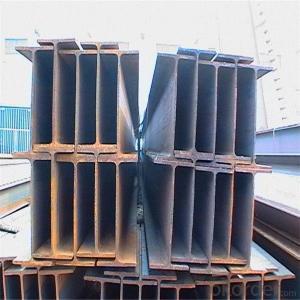

High Quaulity H Section Steel from China with Good Price

- Loading Port:

- Fuzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 110000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details

OKorder is offering H BEAM at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

We can provide qualify goods,competitive price and speedy delivery.

Products Description

H Type Steel Size and Theoretical Weight | |||||

Size | Theoretical Weight | Size | Theoretical Weight | Size | Theoretical Weight |

|

|

|

|

|

|

(mm) | (kg/m) | (mm) | (kg/m) | (mm) | (kg/m) |

100*50*5*7 | 9.3 | 250*125*6*9 | 29 | 446*199*8*12 | 65.1 |

100*100*6*8 | 16.9 | 250*250*9*14 | 71.8 | 450*200*9*14 | 74.9 |

125*60*6*8 | 13.1 | 294*200*8*12 | 55.8 | 482*300*11*15 | 110.8 |

125*125*6.5*9 | 23.6 | 298*149*5.5*8 | 32 | 488*300*11*18 | 124.9 |

148*100*6*9 | 31.1 | 340*250*9*14 | 36.7 | 496*199*9*14 | 77.9 |

150*75*5*7 | 14 | 300*150*6.5*9 | 93 | 500*200*10*16 | 88.1 |

150*150*7*10 | 20.7 | 300*300*10*15 | 78.1 | 582*300*12*17 | 132.8 |

175*90*5*8 | 18 | 346*174*6*9 | 41.2 | 588*300*12*20 | 147 |

175*175*7.5*11 | 40.4 | 350*175*7*11 | 49.4 | 596*199*10*15 | 92.4 |

194*150*6*9 | 29.9 | 350*350*12*19 | 134.9 | 600*200*11*17 | 103.4 |

198*99*4.5*7 | 17.8 | 390*300*10*16 | 104.6 | 700*300*13*24 | 181.8 |

200*100*5.5*8 | 20.9 | 396*199*7*11 | 56.1 | 800*300*14*26 | 206.8 |

200*200*8*12 | 49.9 | 400*200*8*13 | 65.4 | 900*300*16*28 | 240.1 |

244*175*7*11 | 43.6 | 400*400*13*21 | 171.7 |

|

|

248*124*5*8 | 25.1 | 440*300*11*18 | 120.8 |

|

|

Length=6------12meters | |||||

Packaging & Delivery

Packaging Details: | Packed with waterproof paper and steel banding. |

Delivery Detail: | 15-25 |

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

- Q: Are steel H-beams resistant to chemical exposure or spills?

- Steel H-beams are generally resistant to chemical exposure or spills. Steel is known for its durability and strength, making it less susceptible to damage from chemical substances. However, the specific level of resistance depends on the type and concentration of the chemical involved. While steel is generally resistant to most chemicals, highly corrosive substances or prolonged exposure to certain chemicals may eventually cause deterioration and compromise the structural integrity of the H-beams. Therefore, it is essential to consider the specific chemical environment and consult with experts or manufacturers to ensure the appropriate grade of steel is chosen for the intended application. Additionally, proper maintenance and regular inspections are crucial to identify any signs of corrosion or damage caused by chemical exposure and take appropriate measures to mitigate potential risks.

- Q: Are steel H-beams resistant to pests or termites?

- Pests and termites pose no threat to steel H-beams due to their high resistance. Unlike wood, which can easily be infested and damaged by insects, steel is an inorganic material that holds no appeal for pests. Termites, specifically, are known to consume cellulose found in wood, but not in steel. Consequently, steel H-beams serve as a robust barrier against infestations by pests and termites, establishing them as a dependable option for providing structural support in buildings and various construction endeavors.

- Q: What are the standard sizes of steel H-beams?

- The standard sizes of steel H-beams vary depending on the manufacturer and the specific requirements of a project. However, some common standard sizes include H-beams with heights ranging from 100mm to 1,000mm and flange widths ranging from 50mm to 300mm.

- Q: Can steel H-beams be used in the construction of commercial buildings or offices?

- Yes, steel H-beams can be used in the construction of commercial buildings or offices. Steel H-beams are commonly used in the construction industry due to their strength, durability, and versatility. They provide excellent structural support, making them ideal for constructing large commercial buildings or office spaces. H-beams are designed to withstand heavy loads and provide stability, making them suitable for multi-story constructions. Additionally, steel H-beams can be easily fabricated and installed, saving time and labor costs during the construction process. Overall, steel H-beams are a popular choice for commercial building and office construction due to their structural integrity and efficiency.

- Q: Can Steel H-Beams be used in bridge or infrastructure construction?

- Certainly! Bridge or infrastructure construction can indeed utilize steel H-beams. The construction industry widely employs steel H-beams due to their robustness, endurance, and versatility. These H-beams possess a remarkable capacity for bearing heavy loads, rendering them suitable for the support of substantial burdens in bridge structures. By functioning as primary structural elements in bridge girders, H-beams confer the essential strength and stability required for bridges to withstand diverse loads, including the weight of vehicles and pedestrians. Moreover, H-beams commonly find application in the construction of infrastructure such as buildings, highways, and railway tracks. Their adaptability facilitates efficient construction and affords design flexibility, thus establishing steel H-beams as a favored option in bridge and infrastructure projects.

- Q: How do steel H-beams connect to other structural elements?

- Depending on the particular design and engineering needs of a project, Steel H-beams can be connected to other structural elements in various ways. One common approach involves the use of bolts or welds. When joining H-beams to other steel components like columns or beams, it is common to fasten them together using high-strength bolts. These bolts are inserted through pre-drilled holes in the flanges (the horizontal top and bottom sections) of the H-beam and then tightened with nuts. This establishes a secure and rigid connection between the H-beam and the other structural elements. Another method employed to connect steel H-beams to other structural elements is welding. In this case, the flanges of the H-beam are welded to the adjacent components, ensuring a robust and permanent connection. Welding is often favored when there is a need for high load-bearing capacity and structural integrity. Apart from bolts and welds, other connection methods such as connectors or brackets can also be utilized depending on the specific project requirements. These connectors or brackets are often designed to provide additional strength and stability to the connection between the H-beam and other structural elements. It is important to emphasize that the choice of connection method for steel H-beams is contingent upon various factors, including load-bearing capacity, structural design, and safety regulations. Structural engineers and designers meticulously consider these factors to ensure that the connection is strong, secure, and capable of withstanding the forces and loads imposed on the structure.

- Q: Are Steel H-Beams suitable for art or cultural facility construction?

- Indeed, art or cultural facility construction can benefit from the use of Steel H-Beams. Given their robustness and resilience, Steel H-Beams have become widely adopted in the construction industry. Their exceptional ability to provide support and stability makes them particularly well-suited for the creation of expansive structures like art galleries, museums, and cultural facilities. Moreover, Steel H-Beams can be easily customized and fabricated to meet specific design criteria, thereby facilitating flexibility and innovation in the construction of artistic and cultural spaces. The adaptability of Steel H-Beams, coupled with their capacity to withstand substantial loads and withstand the elements, renders them a dependable option for the development of art and cultural facilities.

- Q: Are steel H-beams suitable for supporting transmission towers?

- Yes, steel H-beams are commonly used for supporting transmission towers. Steel H-beams offer several advantages that make them suitable for this purpose. Firstly, H-beams are structurally strong and have a high load-bearing capacity, which is essential for supporting the heavy weight and wind loads of transmission towers. Additionally, steel is a durable material that can withstand environmental factors such as corrosion and extreme weather conditions. Furthermore, steel H-beams can be easily fabricated and assembled, allowing for efficient construction of transmission towers. Overall, steel H-beams provide the necessary strength, durability, and ease of construction required for supporting transmission towers, making them a suitable choice for this application.

- Q: How do steel H-beams perform in high-wind areas?

- Due to their inherent strength and rigidity, steel H-beams are highly effective in high-wind areas. The structural design of H-beams enables them to withstand bending and twisting forces, making them ideal for withstanding the intense loads produced by strong winds. These beams have a considerable load-bearing capacity and can effectively distribute the wind load along their length, which helps prevent structural failure. The wide flanges and thick web of the H-beam shape provide additional stability against wind forces. The flanges function as wings, creating a larger surface area that reduces the wind pressure on the beam. This design feature minimizes the risk of the beam being pushed or bent by the wind. Moreover, steel is a robust and durable material that exhibits exceptional resistance to weathering and corrosion. This quality makes steel H-beams particularly well-suited for high-wind areas, where exposure to harsh weather conditions, such as saltwater or heavy rain, is common. To ensure optimal performance in high-wind areas, it is crucial to consider the specific design requirements and wind loads that a structure may encounter. Engineers employ various methods, such as wind tunnel testing and computational fluid dynamics, to accurately predict the wind forces and select appropriate H-beam sizes and configurations. Additionally, proper installation and anchoring techniques are vital to ensure the H-beams remain securely in place during severe weather events. In conclusion, steel H-beams are specifically designed to excel in high-wind areas. Their structural properties, including strength, rigidity, and resistance to bending, make them highly dependable for withstanding the forces generated by strong winds. When engineered and installed correctly, steel H-beams offer a safe and durable solution for structures in wind-prone regions.

- Q: Can steel H-beams be used in shopping mall construction?

- Shopping malls can indeed utilize steel H-beams. The construction industry frequently employs steel H-beams due to their robustness, endurance, and adaptability. These beams are specifically engineered to endure heavy loads and provide structural reinforcement, which renders them highly suitable for extensive undertakings like shopping malls. The utilization of H-beams in shopping mall construction can encompass an array of purposes, such as bolstering the roof and floors, constructing structural frameworks, and fortifying the overall stability of the edifice. Furthermore, steel H-beams confer various benefits, including their capacity to span significant distances devoid of supplementary support columns, their ability to withstand fire and corrosion, and their recyclability, thus making them an ecologically responsible choice for construction ventures.

Send your message to us

High Quaulity H Section Steel from China with Good Price

- Loading Port:

- Fuzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 110000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords