Optima PVC Ceiling Panels with Various Colours

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

Specifications

PVC Ceiling Panels

1.Thickness:5-12MM

2.Width:100-300MM

3.Length:It depends,like 5.8M,5.95M

4.Advantage:Economic,Durable

Main introduction of PVC Ceiling Panels

1.Thickness:5-12MM

2.Width:100-300MM

3.Length:It depends,like 5.8M,5.95M matching with the size of containers.

4.Type: Flat or with a groove in the middle of panels.

5.Contents of PVC panels: normal & popular PVC percentage is 40%, 45%, 50%, 55% or 60%, balance is calcium carbide or other carbonate.

6.Surface treatment:

1)Normal oil printing.

2)Hot stamping.

3)Thermal transferring print

4)Laminated print

7.Surface finishing effect: White / Glossy / High glossy / Gleam etc.

8.Applications:Home kitchen,bathroom,indoor,hotels,hospitals,commercial buildings,meeting room,schools etc

9..Advantage:

1)Economic,Durable.

2)Light in weight and easy to install / assemble with smooth surface,without gap while fixed together.

3.Image

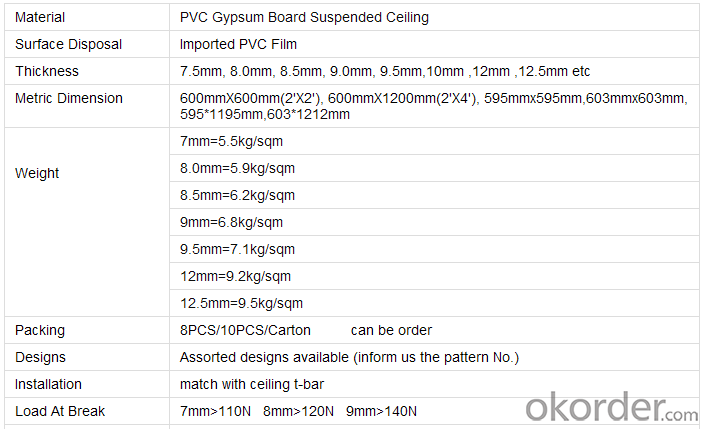

4.Detailed Specification

5.FAQ

Our service

1.All of our goods will pass THREE QUALITY INSPECTIONS before shipment.

2.Best after sale service, customer can follow their order situation any time, no matter on

product line, warehouse or shipment.

3.More than 10years experience in exporting to make your order more smooth.

4.Less than one container loading is accepted.

5.On time delivery, in general 15~25 days.

6.Multimode payment:T/T,L/C,Western Union,D/P,Escrow,Cash..

7.Special dimensions available according to request.

8.We have many certificates of our tiles

9.Company comprehensive capabilities verified by TüV Rheinland for your reference.

- Q: I have a blank PVC gusset plate, plastic material. I want to buy some heat transfer film transfer up, but do not know what equipment through the heat, the general plane thermal transfer machine can it? I am worried that the plastic buckle into the thermal transfer equipment will heat deformation. Please recommend a transfer on the plastic equipment, thank you! Do you buy some blank thermal transfer film through the printer can be printed after the thermal transfer to plastic up?

- Civilian 1610uv printer, printing format 160cm * 100cm, four DX5 nozzle or 5 gs508 nozzle configuration, price 7w-15w. Printing speed of 4-15 square meters / hour. Printing areas are leather, tiles, etc., high-precision, high-speed shop shop equipment. Large 2513 universal printer, printing format 250cm * 130cm, four DX5 nozzle or 4-14 gs508 nozzle configuration or 4-14 gs1024 nozzle configuration, price 16w-60w. Printing speed of 15-80 square meters / hour. Printing areas are glass sliding doors, backdrop, advertising materials, high-precision, high-speed factory batch production equipment.

- Q: Why do some people tell me when there is a lot of scratches on the color of the polished surface.

- PVC board after polishing the appearance of a color does not appear on the scratches, which is mainly because PVC its material surface is smooth, but the hardness and wear resistance and not, it is easy to scratch or grind scratches, but you It will be polished for polishing.

- Q: Pvc board ceiling each piece of zero sale!

- Should be called plastic buckle plate, cheap more than twenty square, good sixty-seven square square

- Q: We have a hot water leak in the house that could lead to break the floor slab for repairs. The plummer plans to reroute the hot water pipe to pass through the ceiling instead on the floor but suggested to use pvc or plastic pipe? He said he's been doing it for about 6 yrs and encounter no problem? What's your idea?

- Pvc Pipe For Hot Water

- Q: MY girlfriend is using a 10' piece of 4 PVC to make a cat tree. About half way up, we put a wye joint in to make a shelf. The post will be fixed to the floor and ceiling. The problem is that the post flexes back and forth at the wye joint. I used silicone, but it didn't help the movement. Is there some kind of expanding caulk I could use? Any other ideas on how to keep it stable?

- I'm guessing that you haven't installed it yet? When you attach it firmly to both the floor and ceiling, it should become very stable. I don't think that you'll have to add any structure. (Unless she has a really big cat...)

- Q: PVC bathroom cabinet is good

- PVC sheet waterproof deformation of environmental protection without odor flame retardant good At present the market has PVC foam board and particle board paste PVC paper.The latter is fake and shoddy products. Mainstream manufacturers have Wrigley Farnsa Eagle America and Canada, such as silver crystal and so on

- Q: I use the PVC wall to do the backdrop, there are three square, one centimeter thick PVC board how to fix to the wall, is the use of glue or nails or other methods, with glue what is the glue. It is best to get their own home to the point of advice Thank you

- Fixed a lot of ways to use plastic bolts with plastic bolts ??? The most easy way to fight a few holes on the wall of a few holes with plastic plastic nail fixed nail surface decorated with a very beautiful hat

- Q: Will pvc floor is how to make out, it is best to specific? Thank you!

- There are many, soft heart. Soft multi-layer lamination. Hard wood plastic, foam and so on

- Q: KT board and PVC board, as well as ABS board What is the difference between ah

- Kt board is polystyrene material (lunch box material) foam out of the plate, the biggest feature is the light mainly used for indoor advertising; Pvc plate - also known as pvc foam board or Andy board, its chemical composition is polyvinyl chloride. Widely used in passenger cars, train car roof, box core layer, interior decoration board, building exterior panels, interior decoration board, office, residential, public places building compartment, commercial decoration rack, clean room board , Hot plate, special cold-keeping project, environmental protection board mold, sports equipment, breeding materials, and other materials, the use of anti-corrosion, , Beach water-proof facilities, water-resistant materials, art materials and a variety of lightweight partitions instead of glass ceiling. (The general plastic pipe with this material is called pvc but not foam) ABS board ABS board ABS board is a new material in the sheet industry. Its full name is acrylonitrile / butadiene / styrene copolymer plate. English name Acrylonitrile-butdiene-styrene, is the largest production, the most widely used polymer. It will PS, SAN, BS various properties organically unified, both tough, hard, just equal balance of excellent mechanical properties. (Refrigerator, air conditioning these are used in this material) Some nouns do not necessarily know what is written in brackets is usually easy to see you see, the main you really understand the

- Q: Will pvc board can do goldfish tank?

- Do is certainly nothing, there are special PVC fish tank with PVC board, you can use hard PVC board, you can also use acrylic to do.

Send your message to us

Optima PVC Ceiling Panels with Various Colours

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords