PVC Ceiling Tiles in Nigeria - Flexible High Quality PVC Panel Ceiling of New Designs

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description

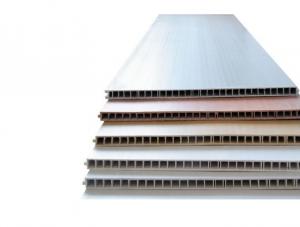

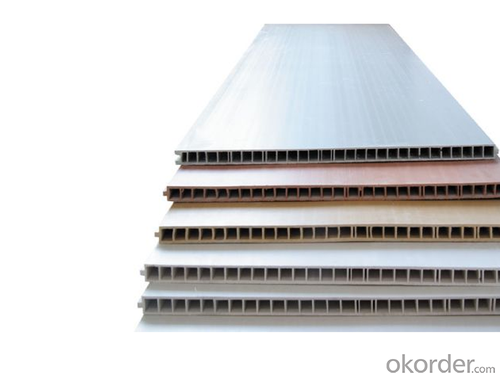

PVC Panel, PVC ceiling, PVC wall panel and PVC siding panel are a kind of decoration material which are

mainly made of PVC resin and calcium carbonate and widely applied in indoor and outdoor decorating,

bathroom ceiling and kitchen ceiling, hotel and office ceiling, outdoor and indoor wall decoration, etc.

It can be very easy installed and cleaned.

Product specification

Thickness (mm): 5mm/5.50/6mm

Width (cm): 500px

Length (m): 0.595-5.95 (according to customer requests)

Weight(kg/SQM): 1.60kgs/1.70kgs/1.80kgs

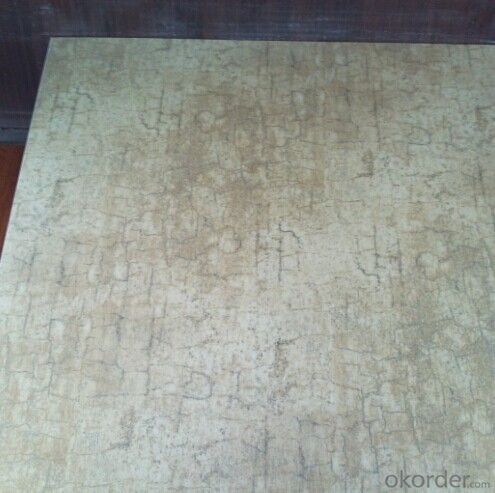

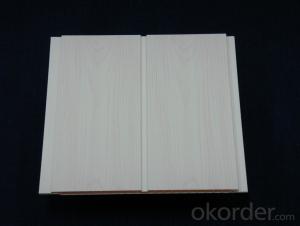

Surface Treatment

Common and High glossy Printing, transfer printing, Laminating with permanent glue, any design as

customer request

Package

PE Film Packing, PVC Film Packing, Hard Paper Box Packing

Features

1. Surface treatment: printing, transfer printing and lamination with permanent glue

2. High intensity, high breaking strength, strong colour fastness not easy to deformation, erosion resistant,

mothproof, sound insulation, waterproof, flame retardant, antibiosis, environmental and non-toxic material ,

3. Easily installation, smooth surface, flat, without gap when concatenated

4. more than 500 colors and designs available

5. Competitive price, high quality and good service

6. Useful life more than 30years

7. Pass ISO9001-2008, Nigeria Soncap, NFPA701, B1,B2, M1,M2 and ROHS certificate

Application

Widely Applied indoor and outdoor decoration, House Ceiling, Hotel Ceiling, Restaurant ceiling, Hospital

and school ceiling, indoor and outdoor wall decoration, etc.

Advantage

Lightweight, easy to install, Quick delivery time, Strong color fastness, Strong Breaking strength,

Reasonable raw material matching rate, easy to clean, heat insulation, sound insulation, waterproof,

flame retardant, antibiosis, environmental and non-toxic material

Supply Ability

500000sqm/month

Minimum Order

one 20’’ container

Delivery Time

10-15days

Payment Term

T/T or LC at sight

Price Term

FOBSHANGHAI or CNF (Competitive Freight)

Frequently Asked Questions

(1) Where are the ceiling panel can be used?

The panels are designed for covering internal walls or ceilings in any room in the home or commercial rooms.

Especially for the wet environment, such as the kitchen and the bathroom.

(2) How can I install the panels?

Our panels are designed to be installed by the DIY’S. We also provide you with the profiles of installation,

You need very little experience and no special tools.

(3) What temperature range I can use plastic panels in?

Our decorative panels can withstand temperatures up to 140°F (60°C)

- Q: PVC floor development prospects

- Isrock, pvc lock the floor. Suitable for home improvement and tooling. With the city search field of all the pvc floor are not the same

- Q: Pvc stamina board can drill their own?

- Yes, but before installation, it is recommended to re-drill, according to the recommendations provided by the manufacturers to install, the plate itself has the characteristics of thermal expansion and contraction, need to reserve space. Hope that the above answer can help you, thank you.

- Q: How to deal with matte PVC mat noodles

- Late hot or sandblasting or chemical corrosion bar. Anyway, there are so few surface treatment

- Q: Colored PVC board is what kind of board ah, can not paint

- Since it is colored .. and need to brush what paint it .. PVC board is a ceiling with .. directly hanging on it, never need to paint.

- Q: Pvc stone floor with hot water bubbles after the UV layer can be torn from the floor, and then you can smell the irritating smell, the business that no formaldehyde, but I think this taste UV layer is certainly sticking up and not hot The

- No. Pvc floor from the structure of the main multi-layer composite and homogeneous through-heart and semi-homogeneous body type 3. The so-called multi-layer composite PVC floor is that it is a multi-layer structure, generally from 4 to 5 layers of laminated structure, generally wear-resistant layer (including UV treatment), printing film, glass fiber layer, Foam layer, grass-roots level. UV treatment is the use of epoxy resin for surface reinforcement in a way that can play anti-pollution and effective absorption of ultraviolet light, enhance wear resistance, delay product aging and easy to clean the role.

- Q: Can I use PVC flooring on a factory floor?

- Factory workshop can be used. PVC flooring is a very popular in the world today, a new type of lightweight ground decoration materials, also known as "light body material." Is a popular in Europe and the United States and Asia, Japan and South Korea's popular products, popular in foreign countries, from the early 80s began to enter the Chinese market, so far in the domestic large and medium-sized cities have been generally recognized, the use of a wide range, such as family, Schools, office buildings, factories, public places, supermarkets, commercial, sports venues and other places. "PVC floor" refers to the use of PVC material produced by the floor. Specifically, polyvinyl chloride and its copolymer resin as the main raw material, adding filler, plasticizer, stabilizer, coloring agent and other accessories, in the continuous sheet on the substrate, the coating process or by rolling, extrusion or extrusion Craft production.

- Q: PVC decorative plate and clean plate difference

- Clean board more emphasis on the first two words, for the high quality requirements of the product. Application of the environment is more demanding areas. If you are decorating the office and home, I recommend you PVC trim panels over the clean board.

- Q: Acrylic board, Abs board and PVC board What is the difference, which can be cut with electric wire?

- Visual is to do COS props, right? Acrylic board has a special hook knife, you can also use their own one with a saw blade PVC board, then the general use of wire saws, utility knife can also need to practice. There is the PVC board grinding is indeed difficult, forced to use the edge of the need to polish the 502 quick-drying glue to make the surface hardened and then polished ~ must use a large number of coarse sandpaper.

- Q: Can Alcohol Clean Pvc Plate?

- Of course, but to use the high concentration, preferably more than 95%.

- Q: Installation works PVC wire tube castable board inside the plugging dredge there to sell?

- Has processed a wire tube to clear the locator! With the feeling to find the location quite accurate, near the site after reading to me to purchase.

Send your message to us

PVC Ceiling Tiles in Nigeria - Flexible High Quality PVC Panel Ceiling of New Designs

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords