High Quality Pile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

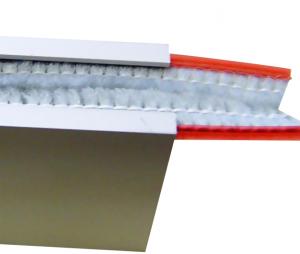

We mainly engaged in manufacturing PHC concrete piles with diameters of Φ600~Φ1400 for wharf. Every year, the company produces various types of concrete piles of over 150,000 meters with single-section pile of 41meter long and annual gross output value up to RMB 600 million.

With years’ manufacturing experience of concrete piles and a great number of excellent technological and management talents, the company persists in technical innovation and research of new products. The large-diameter PHC concrete piles with merits such as good bending strength, large bearing capacity, fine resistance against the external force and so forth have been the preferential choice of structural materials for foundation engineering construction such as large ports, wharfs, shipyard, huge bridges, high-rise buildings, heavy factories, high-speed railway, etc.

The company holds the operation philosophy of “honest, practical and harmonious for win-win” and persists in the quality guideline of “constant improvement with prohibition of non-conforming products into construction site” to provide you sincerely with superior products and service.

- Q: What are the different types of steel wire rod coatings used for increased adhesion?

- There are several types of steel wire rod coatings used to enhance adhesion, including zinc coating, copper coating, tin coating, and polymer coating.

- Q: Can steel profiles be used in industrial renovations?

- Yes, steel profiles can be used in industrial renovations. Steel profiles are commonly used in various construction projects, including industrial renovations, due to their strength, durability, and versatility. They can be employed for structural support, reinforcement, and the creation of frameworks, making them an ideal choice for upgrading and transforming industrial spaces. Additionally, steel profiles can be easily customized and adapted to meet specific project requirements, making them a reliable and popular option in industrial renovations.

- Q: How does the diameter of steel wire rod affect its strength?

- The diameter of a steel wire rod directly affects its strength. Generally, a larger diameter wire rod will have higher strength compared to a smaller diameter wire rod. This is because a larger diameter rod has a greater cross-sectional area, allowing it to withstand higher loads and stresses without breaking or deforming.

- Q: How are steel rails protected from wear caused by train wheels?

- Steel rails are protected from wear caused by train wheels through a combination of preventive measures and maintenance practices. One of the primary methods used is the application of a protective coating to the surface of the rails. This coating, typically made of manganese or chromium, acts as a barrier between the steel rail and the train wheels, reducing friction and minimizing wear. Additionally, regular inspection and maintenance of the rails are crucial in preventing wear. Inspections are conducted to identify any potential defects or damage to the rails, such as cracks, uneven wear, or misalignments. If any issues are detected, prompt repairs or replacements are carried out to ensure the rails remain in optimal condition. Another effective method to protect steel rails is by implementing proper rail lubrication. Lubricants are applied to the rail surface to reduce friction between the wheels and the rails, minimizing wear and tear. This lubrication can be done through various methods, such as the use of solid lubricants, oil-based lubricants, or greases. Furthermore, train operators play a crucial role in mitigating wear on steel rails. They need to adhere to recommended speed limits and ensure trains are not overloaded, as excessive weight and high speeds can accelerate rail wear. Proper training of train operators on efficient braking techniques and maintaining consistent speeds also contributes to reducing wear on the steel rails. In conclusion, a combination of protective coatings, regular inspections, maintenance practices, effective rail lubrication, and responsible train operation is employed to protect steel rails from wear caused by train wheels. These measures aim to prolong the lifespan of the rails, ensuring safe and efficient train travel.

- Q: i was giving this old knive. the knife part is stainless steel and has a couple rust spots but im not sure that the handle is (i think stainless) but it has this un smooth surface i dont think its rust because its not brown. would rubbing alcohol help clean it?

- no if it was stainless it would have not rusted, we use lemon juice and a brillo pad

- Q: What is the role of steel rails in railway signaling systems?

- The role of steel rails in railway signaling systems is to provide a stable and secure path for trains to travel on. The steel rails act as a guide for the train's wheels, ensuring that it stays on track and follows the designated route. Additionally, the steel rails also play a crucial role in transmitting electrical signals for various signaling systems, such as track circuits, which help detect the presence of trains and control their movements. Overall, steel rails are essential for maintaining safety and efficiency in railway signaling systems.

- Q: Can steel H-beams be used for hotels or resorts?

- Yes, steel H-beams can be used for hotels or resorts. Steel H-beams are commonly used in construction due to their strength, durability, and versatility. They provide structural support and can handle heavy loads, making them suitable for large-scale projects like hotels or resorts.

- Q: How are steel strips used in the manufacturing of musical instruments?

- Steel strips are commonly used in the manufacturing of musical instruments for various purposes. One significant application of steel strips is in the production of piano strings. These strings are typically made from high-quality steel wires that are tightly wound around a core steel strip. The steel strip provides stability and strength to the string, enabling it to produce clear and resonant notes when struck by the piano hammer. Steel strips are also utilized in the construction of certain percussion instruments, such as the vibraphone and marimba. In these instruments, steel strips are used as the resonating element, often referred to as bars. The length, thickness, and shape of these steel bars determine the pitch and tone of the notes produced. They are typically mounted on a frame and struck with mallets to create melodic sounds. Another application of steel strips in musical instruments is in the manufacturing of guitar strings. While the core of guitar strings is usually made of steel wire, the winding around the core often consists of a thin steel strip. This steel strip is coated with a layer of bronze or nickel and wound tightly around the core, providing durability, flexibility, and a unique tonal quality to the strings. Overall, steel strips play a crucial role in the manufacturing of musical instruments, particularly in the production of piano strings, percussion instrument bars, and guitar strings. These strips contribute to the sound quality, durability, and playability of the instruments, allowing musicians to create beautiful melodies and harmonies.

- Q: Can steel round bars be used for making propeller shafts?

- Yes, steel round bars can be used for making propeller shafts. Steel is a commonly used material for propeller shafts due to its strength, durability, and resistance to corrosion. Round bars, in particular, are often chosen for their shape, which provides optimal strength and load-bearing capabilities. The selection of steel grade and specific properties will depend on the requirements of the propeller shaft, such as the desired length, diameter, and torque capacity. Additionally, other factors like cost, weight, and manufacturability may also influence the choice of steel round bars for propeller shafts.

- Q: What is the fatigue strength of a steel strip?

- The fatigue strength of a steel strip refers to its ability to withstand repeated loading and unloading cycles without failure. It is a measure of the strip's resistance to fatigue and is typically determined through fatigue testing.

Send your message to us

High Quality Pile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords