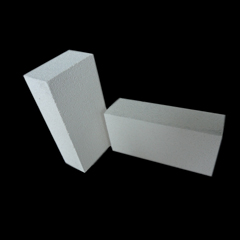

High Quality Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

CMAX insulating firebricks are classified under temperature

between 1100℃ to 1700℃, manufactured from high purity alumina

clay.

Quick Details

| Place of Origin: | Shape: | Material: | |||

| Model Number: | Brand Name: | brick: |

Packaging & Delivery

| Packaging Detail: | wooden pallet |

| Delivery Detail: | in 30 days |

Specifications

1.NG series clay insulation brick

2.Bulk Density:0.6,0.7,0.8,0.9,1.0

4.STD size:230 x 114 x65 mm

Product Index | NG-1.0 | NG-0.9 | NG-0.8 | NG-0.7 | NG-0.6 |

Bulk density g/cm3 | ≤1.0 | ≤0.9 | ≤0.8 | ≤0.7 | ≤0.6 |

Cold crushing strength kg/cm2 | ≥35 | ≥25 | ≥25 | ≥25 | ≥20 |

Permanent linear change temp. | ≥1350 | ≥1300 | ≥1250 | ≥1250 | ≥1200 |

Thermal conductivity 350oC±25 W/m·k | ≤0.5 | ≤0.4 | ≤0.35 | ≤0.35 | ≤0.25 |

- Q: Can insulating fire bricks be used in tundish linings?

- Yes, insulating fire bricks can be used in tundish linings. Insulating fire bricks are made from lightweight refractory materials that have excellent insulating properties. Tundish linings are typically exposed to high temperatures and thermal shocks, which can lead to rapid wear and tear. By using insulating fire bricks, the tundish lining can be protected from excessive heat and thermal stresses. These bricks have low thermal conductivity, which helps to minimize heat loss and maintain a stable temperature inside the tundish. Additionally, insulating fire bricks have good mechanical strength and can withstand the mechanical stresses typically experienced in tundish operations. Overall, using insulating fire bricks in tundish linings can help to improve thermal efficiency, reduce energy consumption, and extend the service life of the tundish.

- Q: Do insulating fire bricks have a high fireproof rating?

- Insulating fire bricks indeed have a high fireproof rating. These bricks are specifically designed to withstand extremely high temperatures and provide excellent insulation against heat transfer. They are made from special refractory materials that have low thermal conductivity, which helps in retaining heat and preventing it from escaping the system. Insulating fire bricks can withstand temperatures ranging from 2300°F to 3100°F (1260°C to 1700°C), making them ideal for use in furnaces, kilns, fireplaces, and other high-temperature applications. Their high fireproof rating ensures that they can effectively protect structures and equipment from the intense heat and flames, allowing for safe and efficient operation in various industries.

- Q: Is it possible to recycle broken insulating fire bricks?

- Yes, it is possible to recycle broken insulating fire bricks. Insulating fire bricks are commonly made from materials such as clay and alumina, which can be recycled. The broken bricks can be crushed into small particles or ground into a fine powder, and then mixed with other materials to create new bricks or other construction materials. Additionally, some recycling facilities may accept broken insulating fire bricks and process them for reuse in other industries. Recycling broken insulating fire bricks helps to reduce waste, conserve resources, and minimize the environmental impact associated with manufacturing new bricks from scratch.

- Q: Can insulating fire bricks be used as a refractory lining material?

- Insulating fire bricks can indeed serve as a refractory lining material. Their purpose is to effectively insulate against heat transfer by having low thermal conductivity. This quality makes them suitable for applications that necessitate the maintenance or control of high temperatures, such as kilns, furnaces, and industrial ovens. High-temperature environments require refractory lining materials to safeguard their structure against the intense heat generated within. These materials must withstand thermal shocks, chemical reactions, and mechanical stresses that occur during operation. Insulating fire bricks are a prime choice for refractory lining applications due to their exceptional thermal insulation properties and high temperature resistance. In addition to being excellent insulators, insulating fire bricks have the added benefit of low density, making them lightweight and easy to handle and install. This advantage proves useful in applications where weight is a concern or where frequent replacement or repair of refractory linings is necessary. It is important to acknowledge that the specific type and composition of insulating fire bricks may vary, and different applications may require different properties. Therefore, it is vital to consult with a refractory engineer or supplier to guarantee that the chosen insulating fire bricks are appropriate for the specific requirements of the application.

- Q: Are insulating fire bricks resistant to pests or rodents?

- Insulating fire bricks are not specifically designed or treated to be resistant to pests or rodents. While the dense nature of these bricks may make it more difficult for pests or rodents to chew through them compared to other materials, they are not completely immune to infestations. If you are concerned about pests or rodents, it is advisable to take additional measures such as sealing any gaps or cracks in the brickwork, ensuring proper ventilation, and implementing pest control methods as needed.

- Q: Can insulating fire bricks be used to build pizza ovens?

- Yes, insulating fire bricks can be used to build pizza ovens. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, making them a suitable choice for constructing pizza ovens. These bricks have low thermal conductivity, which helps retain and distribute heat evenly throughout the oven. The insulating properties of the bricks help the oven reach and maintain the desired temperature, allowing for efficient and consistent cooking of pizzas. Additionally, insulating fire bricks are lightweight, making them easier to handle and install during the construction process. Overall, insulating fire bricks are a great option for building pizza ovens due to their ability to withstand high temperatures and provide effective insulation.

- Q: Are insulating fire bricks suitable for insulation in cryogenic applications?

- Insulating fire bricks are indeed appropriate for insulation in cryogenic applications. These bricks are crafted from lightweight refractory materials that possess exceptional thermal insulation qualities. With their low thermal conductivity, high melting points, and ability to withstand extremely frigid temperatures, they are perfectly suited for cryogenic applications. Cryogenic applications entail the handling and storage of materials at exceedingly low temperatures, typically below -150 degrees Celsius (-238 degrees Fahrenheit). Insulating fire bricks are specifically designed to provide efficient insulation in such extreme conditions, effectively preventing heat transfer and maintaining the desired low temperature. Moreover, insulating fire bricks exhibit chemical stability and possess excellent resistance to thermal shock. This means they can endure rapid temperature fluctuations without cracking or deteriorating, which is particularly crucial in cryogenic applications where such variations are commonplace. In addition to their exceptional thermal insulation qualities, insulating fire bricks are lightweight and easy to handle, making them convenient for installation in cryogenic systems. All in all, insulating fire bricks are a suitable choice for insulation in cryogenic applications due to their thermal insulation properties, resistance to high temperatures, chemical stability, and ability to withstand thermal shock.

- Q: Do insulating fire bricks affect the overall aesthetics of a structure?

- Insulating fire bricks do not significantly impact the overall aesthetics of a structure since they are typically hidden within the walls or used in areas where their appearance is not prominently visible.

- Q: Can insulating fire bricks be used in the construction of lime calciners?

- Yes, insulating fire bricks can be used in the construction of lime calciners. Lime calciners require high temperatures to produce lime, and insulating fire bricks are designed to withstand and retain heat. These bricks have low thermal conductivity, allowing them to effectively insulate the calciner and prevent heat loss. Additionally, insulating fire bricks are lightweight, making them easier to handle and install in the construction of lime calciners.

- Q: Can insulating fire bricks be used as insulation for pizza ovens?

- Yes, insulating fire bricks can be used as insulation for pizza ovens. Their high heat resistance and ability to retain heat make them an ideal choice for insulating the oven and maintaining the desired temperature for baking pizzas.

Send your message to us

High Quality Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords