Hot Selling H Beam Profile to Africa Market

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

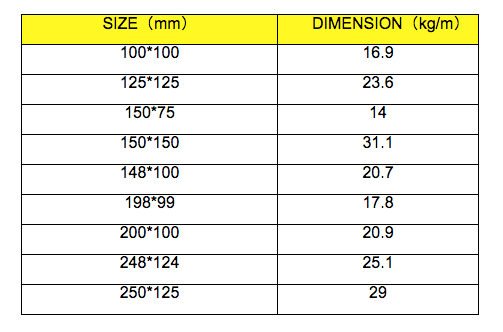

6. Sizes:

Usage & Applications of Hot Rolled Structural Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: Can fit in the containers of 20fts the steel beams of 6M?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: How do steel H-beams contribute to the overall sustainability of a transportation hub?

- There are several ways in which the overall sustainability of a transportation hub is enhanced by steel H-beams. First and foremost, the structural strength and durability of steel H-beams make them an excellent choice for constructing large-scale transportation hubs. With their high strength-to-weight ratio, H-beams require fewer materials to provide the necessary structural support. This not only conserves natural resources but also reduces the environmental impact associated with material extraction, manufacturing, and transportation. Moreover, steel H-beams are recyclable, meaning they can be repurposed or reused once their lifespan is complete. This aligns with the principles of a circular economy, which seeks to minimize waste and maximize resource efficiency. By incorporating recyclable materials like steel H-beams into transportation hub construction, we can decrease the amount of construction waste sent to landfills and promote a more sustainable approach to infrastructure development. Additionally, steel H-beams offer exceptional resistance to extreme weather conditions. They can withstand high winds, earthquakes, and heavy loads, ensuring the long-term stability and safety of transportation hubs. This durability reduces the need for frequent repairs or replacements, saving time and resources in the long run. Lastly, steel H-beams can be prefabricated offsite, allowing for efficient construction processes and minimizing disruption to the surrounding environment. Prefabrication decreases construction time, energy consumption, and waste generation, all of which contribute to the overall sustainability of the transportation hub. In conclusion, steel H-beams have a crucial role in enhancing the overall sustainability of transportation hubs. Their strength, durability, recyclability, resistance to extreme weather, and ability to be prefabricated all contribute to reducing resource consumption, promoting a circular economy, minimizing waste, and ensuring long-term stability. By incorporating steel H-beams into transportation hub design and construction, we can create more sustainable and resilient infrastructure for the future.

- Q: Which is better, I-beam or HN steel?

- Section H steelConvenient drilling, stiffening plate and other additional processesThe thickness of the two legs is inconsistent

- Q: How do steel H-beams contribute to the overall sound insulation of a building?

- Steel H-beams do not directly contribute to the overall sound insulation of a building. Sound insulation is mainly achieved by using materials with high sound transmission class (STC) ratings, such as acoustic insulation, double-glazed windows, and soundproof doors. Steel H-beams, being structural components, primarily provide support and stability to the building structure rather than contributing to sound insulation.

- Q: How to declare the processed H steel? What is the rate of tax refund? Urgent urgent

- First of all, does your company have the right to import and export?! If you have, you can use your company to declare, if not, but also to find a business right to import and export enterprises to help you act as agent.

- Q: What are the different types of connections used for steel H-beams to timber?

- To join steel H-beams and timber, there are several types of connections available. These connections are commonly employed in construction projects that involve the integration of steel and timber components. 1. Bolting: Connecting steel H-beams to timber can be achieved through the widely used method of bolting. This method entails drilling holes in both the steel beam and timber and fastening them together using bolts. This connection method ensures a robust and rigid joint. 2. Welding: Another approach to connect steel H-beams and timber is by welding. This technique involves melting the surfaces of the steel beam and timber together, allowing them to cool and solidify. Welding creates a connection of high strength, but it necessitates specialized equipment and expertise. 3. Steel plates: Steel plates can be utilized as a means to connect steel H-beams and timber. This method involves attaching steel plates to the ends of the beams and then connecting them to the timber using bolts or other fasteners. The utilization of steel plates ensures a durable and dependable connection. 4. Timber connectors: Specific timber connectors are available for connecting steel H-beams and timber. These connectors are specially designed to establish a secure and stable joint between the two materials. Examples of timber connectors include angle brackets, gusset plates, and timber connectors with pre-drilled holes for bolts. 5. Adhesive bonding: In certain cases, adhesive bonding can be employed to connect steel H-beams and timber. This technique involves the application of a strong adhesive between the surfaces of the steel beam and timber, allowing it to cure. Adhesive bonding can establish a strong and long-lasting connection, although its suitability may vary depending on the specific application. It is crucial to consider various factors, such as structural requirements, load-bearing capacity, and project design, when selecting a connection method. Consulting with a structural engineer or a professional in the field is essential to determine the most suitable connection method for steel H-beams and timber in a given construction project.

- Q: What are the dimensions of a steel H-beam?

- The dimensions of a steel H-beam can vary depending on the specific design and manufacturer. However, in general, H-beams are characterized by their height, width, and weight per foot. The height of an H-beam refers to the vertical distance from the top to the bottom flange, while the width is the horizontal distance between the two flanges. The weight per foot indicates the amount of steel used in a linear foot of the beam. These dimensions can vary widely depending on the intended use and load-bearing requirements.

- Q: Can steel H-beams be used for supporting heavy machinery?

- Indeed, heavy machinery can be effectively supported by steel H-beams. These H-beams are specifically engineered to possess exceptional strength and durability, rendering them exceptionally suitable for bearing substantial loads. Their robust load-bearing capacity has established their widespread application in the construction and industrial sectors, particularly for bolstering heavy machinery like cranes, gantries, and large equipment. The structural configuration of H-beams enables efficient distribution of weight, guaranteeing stability and safety during the support of hefty loads. Furthermore, steel H-beams exhibit remarkable resistance against deformation, corrosion, and various environmental elements, thereby solidifying their reputation as a dependable choice for sustaining heavy machinery.

- Q: What are the considerations when designing for thermal bridging in Steel H-Beams?

- When designing for thermal bridging in Steel H-Beams, there are several important considerations to keep in mind. Firstly, it is crucial to consider the thermal conductivity of the steel material itself, as it can significantly impact heat transfer through the beams. Secondly, the design should account for the potential for thermal bridging at connections or joints, where heat can easily transfer between the beams and the surrounding components. Insulation materials or thermal breaks can be implemented at these points to minimize heat loss. Additionally, the overall design should aim to minimize the surface area of the beams that is exposed to the exterior environment, as this can reduce the potential for heat transfer. Proper insulation and thermal analysis should be performed to ensure that the H-Beams meet the required thermal performance standards and minimize energy loss.

- Q: How do steel H-beams perform in structures with large spans and cantilevers?

- The excellent strength-to-weight ratio and structural stability of steel H-beams make them widely used in structures with large spans and cantilevers. These beams can withstand heavy loads and provide maximum support over extended distances. Applications such as bridges, stadiums, warehouses, and industrial buildings benefit from the superior load-bearing capacity of steel H-beams. They allow for longer distances between support points, thanks to their H-shape that provides increased strength and rigidity against bending and deflection under heavy loads. Steel H-beams are also beneficial for cantilevers, as their inherent strength allows for longer cantilever lengths without compromising structural integrity. This is particularly useful in architectural designs that require open spaces or unique configurations, like cantilevered balconies, overhangs, or roof extensions. Construction methods and connections are made easier with steel H-beams, as they can be easily welded or bolted together. Their wide flanges provide ample surface area for attaching other structural components, such as columns, girders, or floor systems. Furthermore, steel H-beams offer excellent resistance to fire, corrosion, and weathering, making them suitable for both indoor and outdoor applications. Their durability ensures long-term performance and minimal maintenance requirements. In conclusion, steel H-beams are an ideal choice for structures with large spans and cantilevers. Their strength, stability, and versatility make them highly effective in supporting heavy loads and achieving architectural designs that require extended distances or unique configurations.

- Q: Can steel H-beams be used in airport or terminal construction?

- Yes, steel H-beams can be used in airport or terminal construction. They are commonly utilized in the construction of large structures like airports or terminals due to their high strength, versatility, and ability to support heavy loads. The H-beams provide structural stability and are often used for framing, columns, or support beams in the construction of these buildings.

Send your message to us

Hot Selling H Beam Profile to Africa Market

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords