Hot-Dip Galvanized Steel Coil with Very Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-Dip Galvanized Steel Coil Used for Industry

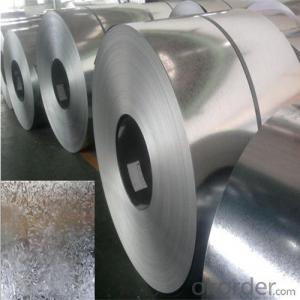

1.Structure of Hot-Dip Galvanized Steel Coil Description

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful countless outdoor and industrial applications.

2.Main Features of the Hot-Dip Galvanized Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

3. Hot-Dip Galvanized Steel Coil Images

4. Hot-Dip Galvanized Steel Coil Specification

Hot-Dip Galvanized Steel Coil | |

Thicknenss | 0.10mm-5.00mm |

Width | 2000mm max |

Coating mass | 30-600g/㎡ |

Spangle | Regular/Minimized/Zero Spangle |

Coil inner diameter | 508-610mm |

Surface treatment | Chromated/non chromated, Oiled/non oiled, Anti finger print |

5.FAQ of Hot-Dip Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: i'm looking into buying a stainless steel ring for somebody as a gift.i'm on a budget (heh) and the ring is about $50.will it rust or tarnish? it'd be embarrassing if i gave it to someone, and it begins rusting :Pthanks

- Stainless steel is a generic term for a huge variety of different alloys. In manufacturing, each steel has different numbers, etc that they go by. Some steel sold as being stainless actually is not. It rusts, like the cheap kitchen knives you see that are left in the sink too long. However, the stainless in jewelry is pretty legit. Overpriced, but legit. It will not tarnish, but it won't stay shiny forever. It might get a little less glossy over time. When it does get re-polished, it takes a long time to do it. But it will not turn black or rust. Good luck.

- Q: I'm not really sure if carbon steel is considered a metallic material.

- yes its iron with carbon in it

- Q: Please people suggest me how can I select external finishing for Steel Building as there is a wide range of choice available.

- Hi okorder /

- Q: During fatigue testing of any material (especially for steels), why is strain-control mode preferred over stress control mode?

- because metals, like steel, are ductile and will stretch before breaking. Straining the metal is stretching it, stressing the metal is applying a shearing force or bending until there is an actual metal failure. A sheet metal strap 1inch across and 24 gauge metal is commonly used to support metal ducting systems in construction. These have an average strain to failure weight load as high as 16,200 lbs. As reported by the smacna index, they will safely hold 6800 pounds. Of more interest is the screws used to hold the strap to the duct. While they are grade 3, fairly strong, they strain to 1400 pounds when properly installed, and are safely able to support 650 pounds, unless they are overtorqued (stripped) and this quickly drops to 400 pounds and 125 pounds...big difference.

- Q: What are the different methods of cut-to-length shearing for steel coils?

- Steel coils can be cut-to-length using various methods, each with unique advantages and applications. Some commonly used methods include: 1. Rotary Shearing: This technique utilizes a rotating shear blade to cut through the coil. It offers excellent precision and can handle a wide range of material thicknesses. Rotary shearing is well-suited for high-volume production and allows for high cutting speeds. 2. Guillotine Shearing: In this method, a straight blade is employed to cut through the coil. It is a versatile technique that can handle different material thicknesses and widths. Guillotine shearing is relatively simple and efficient, making it a popular choice for many applications. 3. Slitting: Slitting involves creating multiple longitudinal cuts in the coil to produce narrower strips. It is commonly used when a coil needs to be divided into smaller coils or when narrower strips are necessary for specific applications. Slitting can be performed using either rotary or straight blades. 4. Laser Cutting: Laser cutting employs a high-powered laser beam to melt or vaporize the material, resulting in a precise and clean cut. It is ideal for cutting complex shapes or patterns and can handle both thin and thick steel coils. Laser cutting offers high accuracy and minimal material distortion. 5. Waterjet Cutting: In this method, a high-pressure stream of water mixed with abrasive particles is used to cut through the coil. It is suitable for a wide range of materials, including steel, and can achieve high accuracy. Waterjet cutting is often utilized for cutting thick coils or when minimizing heat-affected zones is crucial. Each method has its own strengths and limitations, and the selection depends on factors such as material thickness, required precision, production volume, and specific application requirements. Choosing the most suitable method is vital to ensure efficient and high-quality cut-to-length shearing for steel coils.

- Q: What are the common applications of galvanized steel coils?

- Galvanized steel coils are commonly used in a variety of applications such as construction, automotive manufacturing, and the production of household appliances. They are used for roofing, siding, and structural components in buildings due to their corrosion resistance and durability. In the automotive industry, galvanized steel coils are used for manufacturing car parts, such as body panels and frames, to enhance their strength and longevity. Additionally, they are utilized in the production of household appliances like refrigerators, washing machines, and air conditioning units, as the galvanized coating protects against rust and extends the lifespan of these products.

- Q: How are steel coils used in the production of steel framing systems?

- Steel coils are used in the production of steel framing systems as they are typically unwound and fed into a roll forming machine where they are shaped into the desired profiles and sizes required for the framing components.

- Q: When I got my AR-15 I was told that I should get either get Brass or Steel Case ammo and stick with one or the other, I was wondering why? It surely wouldn't damage anything switching back and forth between the two would it? I got steel case ammo and I have stuck with It and probably will either way, I was just wanting to know it I ever wanted to get some Hornady's or somthing like that.

- When I first got my ar i used 500rds of wolf steel but since i heard its bad I only use brass but I did shot 30rds of steel then 30rd brass one time at the range and I have not had any problems with it. I have put 700rds though it 500 steel.

- Q: How do steel coil manufacturers contribute to local economies?

- Steel coil manufacturers contribute to local economies in several ways: 1. Job creation: Steel coil manufacturing facilities require a significant workforce to operate, including skilled workers, engineers, technicians, and support staff. By establishing and expanding manufacturing plants, steel coil manufacturers create employment opportunities for local residents. This leads to reduced unemployment rates and increased income levels, which in turn stimulates local spending and economic growth. 2. Supplier networks: Steel coil manufacturers rely on a wide range of suppliers for raw materials, equipment, and services. This creates a network of local businesses that benefit from the demand generated by manufacturing operations. These suppliers include steel producers, logistics companies, packaging providers, maintenance service providers, and many others. The presence of a steel coil manufacturer can stimulate the growth and development of these local businesses, enhancing the overall economic vitality of the region. 3. Secondary industries: The steel coil manufacturing industry acts as a catalyst for the development of secondary industries. These industries include steel fabrication, construction, automotive manufacturing, machinery production, and many others that rely on steel as a primary input. The presence of a steel coil manufacturer in a local economy can attract and support the growth of these industries, leading to increased economic activity and job opportunities. 4. Tax revenue: Steel coil manufacturers contribute to the local economy through the payment of various taxes. These include corporate income taxes, property taxes, sales taxes, and employment taxes. The tax revenue generated by these manufacturers is often significant and can be used by local governments to fund public infrastructure projects, education, healthcare services, and other essential services that benefit the community. 5. Economic multiplier effect: The economic impact of steel coil manufacturers extends beyond their direct operations. The presence of these manufacturers attracts other businesses and industries to the region, leading to a multiplier effect. For example, steel distributors, fabricators, and processors may establish operations nearby to take advantage of the proximity to the manufacturer. This creates a cluster of related industries that further contribute to the local economy, creating a self-sustaining cycle of economic growth and development. In summary, steel coil manufacturers contribute to local economies by creating jobs, supporting local suppliers, stimulating secondary industries, generating tax revenue, and triggering an economic multiplier effect. Their presence enhances the economic vitality of the region, leading to increased employment opportunities, income levels, and overall economic growth.

- Q: 1943 steel pennies

- if you collect coins, you need to learn that they must never be cleaned. cleaning, while it might make them look pretty, ruins their value as a collectable. ask your coin dealer.

Send your message to us

Hot-Dip Galvanized Steel Coil with Very Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords