High Quality Graphite Electrode Chemistry for Steel Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications

Graphite Electrodes Used for steel making in arc furnace

Dia:200mm-500mm

Super quality

Competitive price

2. Specifications for RP, HP, UHP graphite electrodes with nipples:

RP | HP | UHP |

Electrode: Bulk Density≥ 1.56g/cm3 Elastic Modulus≤ 9.3GPa Thermal Expansion Coefficient≤ 2.7x10 -6/°C Ash≤ 0.5%

Nipple: Bending Strength≥ 14.0MPa Elastic Modulus≤ 13.7GPa Thermal Expansion Coefficient≤ 2.5 x10 -6/°C Ash≤ 0.5% | Electrode: Bulk Density≥ 1.65g/cm3 Elastic Modulus≤ 10.0GPa Thermal Expansion Coefficient≤ 2.2x10 -6/°C Ash≤ 0.3%

Nipple: Bending Strength≥ 16.0MPa Elastic Modulus≤ 14.0GPa Thermal Expansion Coefficient≤ 2.0 x10 -6/°C Ash≤ 0.3% | Electrode: Bulk Density≥ 1.68g/cm3 Elastic Modulus≤ 14.0GPa Thermal Expansion Coefficient≤ 1.9x10 -6/°C Ash≤ 0.2%

Nipple: Bending Strength≥ 18.0MPa Elastic Modulus≤ 16.0GPa Thermal Expansion Coefficient≤ 1.4 x10 -6/°C Ash≤ 0.2% |

3. Packing:

In wooden cases strapped with steel bands.

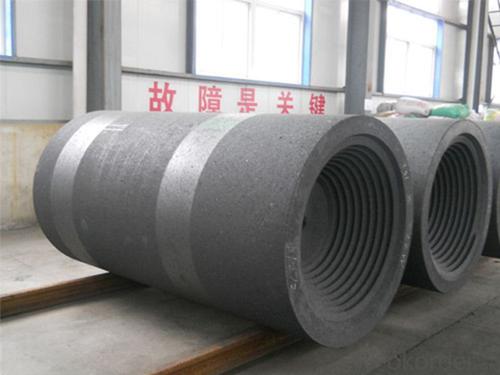

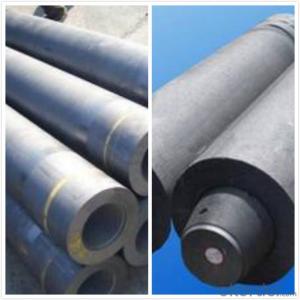

4.Pictures of Graphite Electrodes Factory

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty Graphite Electrodes with high power ?

Our factory could produce qualified products and good delivery time, cause we have many graphite electrodes in stock to our clients. So we can offer you stock products if you need urgent.

②How to guarantee the quality of the products Graphite Electrodes with high power?

We have established purchasing quality control system, and we have inspector in the factory to check the quality. each good should be appreoved by the inspectors ,then, could be permit to do shipment.;

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory to do production or do delivery as cusotmers' request.

- Q: Why is graphite conductive electrode oxidized?

- Graphite electrode uses petroleum coke (carbon), pitch coke (carbon) as granule material

- Q: Classification, uses and manufacturers of graphite electrodes

- The difference between graphite electrodesMainly from the current, density, resistance, bending strength, ash parameters are measured

- Q: In EDM, the electrodes are made of graphite and copper. Please tell us the difference between them

- Graphite is characterized by coarse particles, fine particles and ultrafine particlesFor different processing, you can choose different particles, the smaller the particle size, the higher the accuracyCopper has good conductivity and thermal conductivity and is used in many occasionsBut there are many factors to consider in the choice between the two

- Q: What's the use of carbon?

- Common power graphite electrode. Allows the use of current density of less than 17A/ cm 2 graphite electrode, mainly used for steelmaking, smelting silicon, yellow phosphorus and other ordinary power furnace.

- Q: Why should graphite paper be placed between the heater and the graphite electrode?

- . Different single crystal furnace heaters may be of the same size or may be different. The heater is determined according to the size of the Czochralski single crystal furnace and the parameters of the drawn single crystal, and is generally designed in the form of a parallel circuit, and the following parameters. A heater, the heater, the shape of two inner diameters of three, four, the effective length of the heater heater, the heater piece is five thickness and gives the heater diameter. These parameters are determined according to Czochralski single-crystal furnace parameters and its crystal diameter. The power transformer parameters are mainly based on the single crystal furnace heating power: maximum output power, maximum output voltage and maximum output current, diameter and height of the crucible. The design of the heater has the following steps: 1. Selecting and determining the shape of the heater; the heater is made of high purity graphite; the resistivity of the high purity graphite; the heater is usually made into a cylinder at present.

- Q: How much does a graphite electrode cost about a ton?

- According to purity and quality, the price is 1-6 tons / tonDo not calculate the processing cost

- Q: How should carbon deposits be treated?

- At certain temperature, can make alloy and carbon can react in the engine surface coated with a layer of graphene film, graphene nano particles can fill the pores, wear scratches, on the friction surface repair function.

- Q: How does graphite produce solar cells?

- The team at the Massachusetts Institute of Technology has confirmed that electrodes based on graphene and ITO devices are comparable in efficiency. Although the power conversion efficiency of graphene is 4.2% lower than that of a general silicon cell, it will be competitive for special use in the future.

- Q: Jiqiu conductive graphite electrode, how to compare with copper is relatively large resistance value?

- Look at what kind of graphite electrode you need. Now, the resistivity of ordinary power graphite electrode in our factory is 7.5-8.5. It is not clear that the graphite electrode is dipped in 6--7.3. copper

- Q: What does graphite electrode GSK mean?

- Graphite board material is GSK, GSK refers to model specifications

Send your message to us

High Quality Graphite Electrode Chemistry for Steel Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords