High Quality Electrolysis Graphite Electrodes for Steel Making

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 700 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Graphite Electrode

Graphite electrode is made from the domestic first class petroleum coke and high quality needle coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc. The Graphite electrodes include: regular power, high power, ultra high power and square electrode. The range of diameters covers from 200mm to 800mm. Our products own the following characteristics: low electric resistivity, good electrical and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanical shock, high mechanical strength, high machining accuracy.

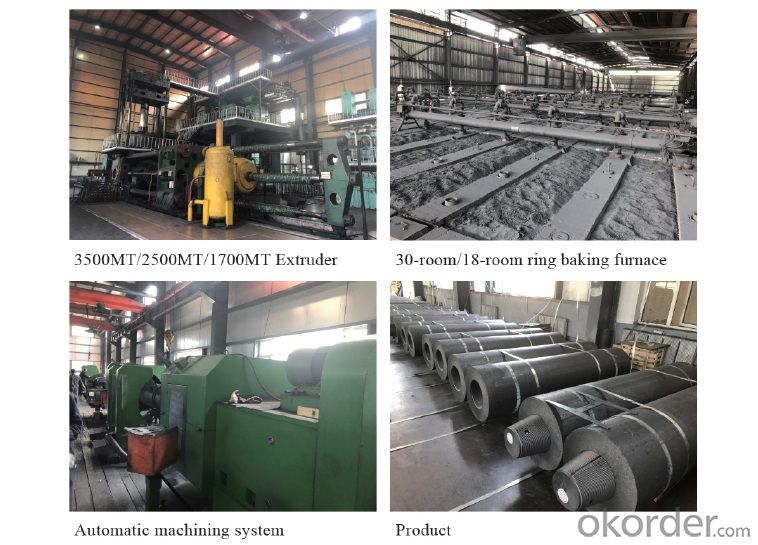

CNBM and its partner have 4 production bases and the annual production capacity of graphite electrodes is 60,000 MT.

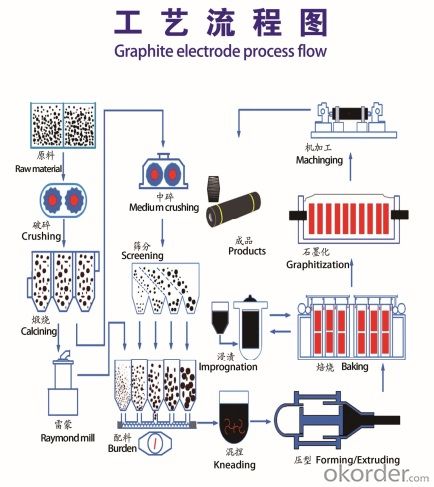

Graphite Electrode Process Flow

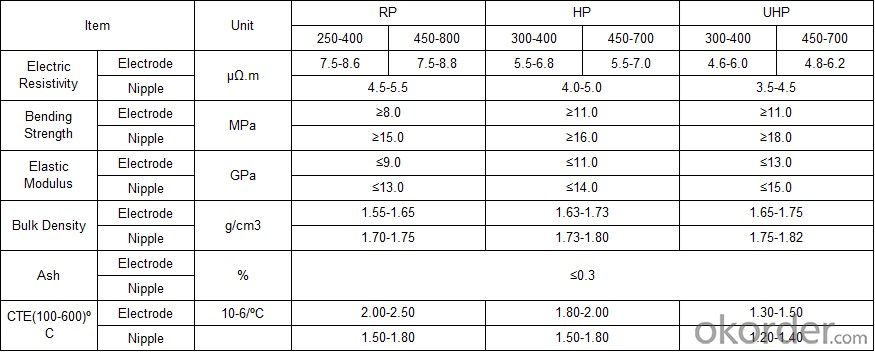

Technical Specifaication:

Company Profile

CNBM INTERNATIONAL CORPORATION

Build your world with our materials.

We are a primary subsidiary of China National Building Material Group Co., Ltd.

CNBM Group is a central government-owned enterprise and a Fortune Global 500 company (Ranking 203th in 2019). It is the largest building material manufacturer and service provider in the world, with 15 publicly-listed companies and over 180,000 employees (2019). We have more than 300 factory plants in China. For the refractory, we are top 3 in China. We have more than 17 plants in different cities.

Production Facilities

Quality Assurance & Control

· National Certified Laboratory

· Key testing instruments, including: specific resistor, bulk density meter, elasticmodulus meter, bending strength inspector, ash analysis meter, CTE analysis meter, etc.

· On-time instrument calibration

· On-site properties testing, including:

L-CTE,C-CTE

Specific resistance, bulk density,

Bending strength, ash content, elastic modulus

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your requirement.

- Q: After electrolysis of CuCl2 solution with graphite electrode for a period of time, we can observe that the graphite surface attached to the DC power supply is attached to the red material,And will the color of the solution be deep or shallow?

- During electrolysis, cations move toward the cathode, electrons are reduced at the cathode, anions are moved toward the anode, electrons are lost at the anode and oxidized. And you use both sides of the graphite rod, is inert electrode, so there will be no copper ions added to the solution, copper in the solution of consumption, the color of natural shallow.

- Q: Will the brush grease not short-circuit the commutator?

- Graphite, on the other hand, has good lubrication. The graphite base electrode will form a layer of carbon film when it rotates on the surface of the motor commutator. It can reduce the friction coefficient between the brush and the commutator and reduce the wear of the commutator effectively.

- Q: Can graphite be used as an electrode for electrolysis of silver in silver nitrate?

- Xiaoyi Liyang said the principle is correct, but can get silver? I think we can solve the problem if we take proper measures to get the silver elements, such as separating the anode and the cathode from the salt water!

- Q: Electrolytic water solution, two electrodes are graphite electrode, the negative electrode can produce large amounts of hydrogen, the anode does not produce half of oxygen, and only a small amount of it?

- The oxygen will react with the graphite and the gas will dissolve.The iron has been oxidized.

- Q: The production of one ton of steel required graphite electrode

- The consumption of graphite electrode in steelmaking in arc furnace, according to the different material, different specifications of graphite electrode used (normal power graphite electrode, high power graphite electrode, ultra high power graphite electrode) have relations.

- Q: Graphite graphite graphite graphite electrode what is the use?

- Of course all conductive graphite gray, conductive powder is used for professional conductive, the conductivity is different, in order to achieve its electrical resistance value, the graphite powder of different particle by the ratio to reach the ideal value of resistance. Graphite powder is pure graphite powder, requirements of mesh consistent, high purity.

- Q: Can high-purity graphite be used as an electrode?

- The high purity graphite electrode has little wear and is suitable for increasing the machining of the cavity;

- Q: 800KVA and 12500 EAF transformer data graphite electrode furnace.

- The graphite electrode must be roasted by a cathode or anode baking furnace, and a large amount of harmful gas and dust will be produced during the roasting process.

- Q: How do graphitized electrodes differentiate between high power and low power?

- In an electrolytic cell, the current from a class called graphite anode plate into the electrolyte electrolysis industry, the anode is made of plate shape, so called graphite anode plate, widely used in electroplating, wastewater treatment, industrial anti-corrosion equipment or special materials.

- Q: What are pyrolytic graphite electrodes used for?

- In 1960s, copper is widely used as electrode material, usage rate of about 90%, about graphite only 10%; in twenty-first Century, more and more users start using graphite as the electrode material, in Europe, more than 90% above the graphite electrode material is. Copper, the once dominant electrode material, has almost lost its advantages over graphite electrodes.

Send your message to us

High Quality Electrolysis Graphite Electrodes for Steel Making

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 700 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords