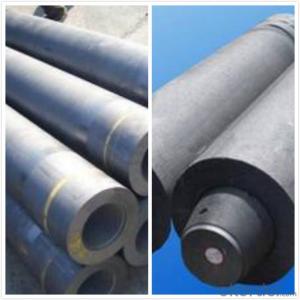

Graphite Electrode for Arc Furnace RP Grade

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 MT m.t.

- Supply Capability:

- 2000 MT m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production Description

Graphite electrode is made from the domestic first petroleum coke and high quality needle coke

and widely used in the electric arc furnaces for production of alloy steels, metal and other

nonmetallic materials, etc. The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode. The range of diameters covers from 200mm to

700mm. Our products own the following characteristics: low electric resistance, good electric and

thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanical shock, high mechanical strength, high machining accuracy.

Applications

Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon, phosphorus, etc.

Programmable properties

1.Good electrical conductivity

2.High resistance to thermal shock

3.High mechanical strength

Grades:RP, RPI, HP, SHP, UHP

Graphite Electrode Grades

General Specifications for Graphite Electrodes

ITEM | Unit | UHP | HP | RP | |||

350-450mm | 500-700mm | 350-450mm | 500-700mm | 350-450mm | 500-700mm | ||

Bulk Density | g/cm³ | 1.65-1.73 | 1.65-1.74 | 1.62-1.72 | 1.62-1.72 | 1.54-1.61 | 1.54-1.61 |

Specific Resistivity | μΩM | 4.2-6.0 | 4.5-5.8 | 5.5-6.8 | 5.6-7.0 | 7.0-9.0 | 7.0-9.5 |

Flexural Strength | Mpa | 11.0-15.0 | 10.0-14.0 | 10.5-14.5 | 10.0-13.5 | 8.0-11.0 | 7.0-10.0 |

Elastic Modulus | Gpa | 8.5-11.0 | 8.0-12.0 | 6.0-9.3 | |||

CTE (100-600)°C | 10-6/C | 1.30-1.45 | 1.65-1.95 | 1.85-2.25 | |||

ASH | % | 0.1-0.3 | 0.1-0.3 | 0.1-0.3 | |||

- Q: How to improve the efficiency of graphite electrode milling, please tell me

- The technical development of the high-speed machining center lays the foundation for improving the milling efficiency and quality of the graphite electrode, especially for the milling of the small electrode with complicated shape and thin wall. In the EDM mold processing, the graphite electrode needs to be processed by the high-speed machining center (HSM), so the demand for HSM machine tools is also increasing. But for some time, because of the technological developments in hard steel processing, it seems possible to make graphite electrodes an obsolete technology.

- Q: Where is the graphite electrode scrap?

- Finally, a bright white Ar-ICP discharge is formed, especially like a drop of water droplets.

- Q: Why should the carbon brush for the trolley be made of graphite?

- Graphite conducts electricity and is self lubricant, resistant to wear. As for why, high school chemistry textbooks have ah.

- Q: In EDM, the electrodes are made of graphite and copper. Please tell us the difference between them

- Graphite is characterized by coarse particles, fine particles and ultrafine particlesFor different processing, you can choose different particles, the smaller the particle size, the higher the accuracyCopper has good conductivity and thermal conductivity and is used in many occasionsBut there are many factors to consider in the choice between the two

- Q: Please senior doubts. The graphite electrode is used in the mold cavity In what case is graphite processing taken?

- Because of the great loss of graphite electrode in finishing, it is not suitable to be used as finishing electrode material. Because of the small coefficient of thermal expansion of graphite, it can also be used as a big electrode material in perforation processing.

- Q: Why is the production of one ton of ultra high power graphite electrode requires 1.05 tons of coke?

- Petroleum coke is divided into needle coke and sponge coke and projectile reef, fixed carbon content components of petroleum coke is around 80%

- Q: Classification of graphite electrodes

- A graphite electrode with a current density of 18~25A/ cm 2 is used, which is mainly used in steel-making of high power arc furnace.

- Q: Graphitized coke, graphite, broken, mixed up, how to export?

- Graphite electrode pieces in different data definition of graphite scrap is different, some data and literature of the graphite particles are called not great pieces of graphite (such as graphite) and some say that graphite products have a certain size, into a block of graphite broken, we are here to say Shi Mosui is second, often called as the graphite block. The production of graphite from graphite products, graphitization and machining process. Graphite waste used as an additive and as a conductive material in the steelmaking and casting industries.

- Q: What is the composition of petroleum coke and what is its use?

- Mainly used for making carbon products, such as graphite electrodes, anode arc, steel, non-ferrous metals, with aluminum for use; silicon carbide products, such as grinding wheel, rubber, sandpaper; producing goods for the production of synthetic fiber, calcium carbide acetylene and other products; also can be used as fuel for fuel, but for grading impact for grinding superfine grinding, through the JZC-1250 device can be made of coke powder after combustion, using coke powder as fuel is mainly some glass factory, coal water slurry plant etc..

- Q: How large is the permissible overload current per square millimeter of the graphite electrode cross section?

- Overhead wires, radiating the best conditions, allowed the current largest. The insulated wire in the house is laid in the wall, which has the worst heat release conditions and the smaller permissible current, so there are different safety currents.

1. Manufacturer Overview

| Location | Shizuishan,China |

| Year Established | 2004 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | " Mid East;Western Europe;North America" |

| Company Certifications | The Authentication certificate of Quality Management system |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 300,00 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Graphite Electrode for Arc Furnace RP Grade

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 MT m.t.

- Supply Capability:

- 2000 MT m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords