HIGH QUALITY Galvanized Steel coils FOR YOUR

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

72104900

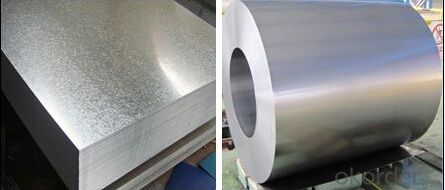

Steel Specification:

Thickness: 0.2-3.0mm

Width: 600-1500mm

Coating Mass: Z08,Z12,Z18,Z20,Z22,Z25,Z27,Z35

Z80,Z120,Z180,Z200,Z220,Z250,Z275

Tolerance for thickness,width,flatness and so on conform to the requirements of JIS G3302 or ASTM A653M/924M

Coil ID can be either 508mm or 610mm, maximum coil OD is 2000mm

The speicfication of ASTM Such as A653m,A924 M and so on have been updated to the latest revisions

Application:

BUILDING & CONSTRUCTION

Floor decks, ceilings, verandas, rolling doors, warehouse, partitions, sheds, gutters, wall, underground piping, sashes, beams, fences, scaffolding, indoor decorations, ducts, ventilating pipes, steel frames and cable trays.

ELECTRICAL APPLIANCES

Freezers, video recorder cases, motor cases, lighting fittings, water heaters, washing machines, refrigerators, stoves, air conditioners, dehumidifiers, fluorescent light housings, electrical heaters, toasters, microwave oven enclosures and switch boxes.

TRANSPORTATION

Containers, under body panels, bus & truck body panels, fuel tanks, noise screens, highway signs, air cleaners, conveyor systems and guard rails.

AGRICULTURAL EQUIPMENT

Barns, drying machines, animal houses, hoppers, irrigation systems, greenhouses, water tanks, sheds, silos, agricultural implements and feeders.

FURNITURE & OTHERS

Vending machines, drums, cans, pails, sauna inner parts, chimney pipes, entertainment machines, solar collectors, office equipment, steel furniture, tool boxes, garages and waste bins.

COMPUTER'S APPLIANCES

Computer shells and communication instruments。

Surface Treatment:

Chromating treatment or anti-finger print

Surface Finished:

REGULAR SPANGLE:

Regular spangle is also called normal spangle which is naturally formed without any additional treatment during galvanizing.

MINI SPANGLE:

The spangle is restrained and formed as mini spangle by reducing the lead content in the zinc liquid or by blowing the zinc powder from the equipment installed on the zinc pot.

EXTRA SMOOTH:

The mini spangle is further skin-passed to produce the extra smooth surface.

- Q: How are steel coils used in the manufacturing of engine mounts?

- Steel coils are used in the manufacturing of engine mounts as they provide strength, durability, and flexibility. These coils are typically used as the main component of the mount, providing the necessary support and stability for the engine. The steel coils are designed to absorb and dampen vibrations, ensuring smooth operation and minimizing the transfer of engine vibrations to the vehicle.

- Q: Is the product of mild steel environmentally friendly? does it produce any emissions?The same question for leather aswell.

- Steel just rusts, it doesn't produce any emissions just sitting there. They even make architectural steel called Corten to rust to a nice patina. If you consider how the steel was made in the first place, a great big NO! Steel making requires massive amounts of electricity plus it gives off some nasty fumes in the liquid state. Leather itself doesn't emit much of anything, but the dyes might. Again though, if you look at how it's made, tanning leather is right up there with steel mills and paper mills for pollution, some of the worst.

- Q: How do steel coils contribute to the manufacturing of construction materials?

- Steel coils play a crucial role in the manufacturing of construction materials by providing a versatile and reliable source of raw material. These coils are manufactured from high-quality steel and are typically used as a primary input in various construction processes. One of the main contributions of steel coils in construction material manufacturing is their ability to be shaped and formed into different products. These coils can be easily cut, bent, and molded to create a wide range of construction materials such as beams, pipes, and sheets. This versatility allows manufacturers to produce customized construction components that meet specific project requirements. Furthermore, steel coils provide strength and durability to construction materials. Steel is known for its exceptional tensile strength, which makes it an ideal choice for load-bearing structures and components. By using steel coils, manufacturers can produce construction materials that can withstand heavy loads, extreme weather conditions, and other environmental factors, ensuring the longevity and safety of the final construction product. In addition, steel coils offer consistency in quality and performance. The manufacturing process of steel coils involves stringent quality control measures, ensuring that the final product meets the required specifications. This consistency in quality gives construction material manufacturers the confidence to produce reliable and high-performance products consistently. Steel coils also contribute to the efficiency of construction material manufacturing. The availability of steel coils in large quantities and standardized dimensions allows for streamlined production processes. Manufacturers can optimize their operations by utilizing automated machinery and processes, reducing production time and costs, and increasing overall efficiency. Overall, steel coils are an essential component in the manufacturing of construction materials. Their versatility, strength, consistency, and efficiency make them a preferred choice for construction material manufacturers. By using steel coils, manufacturers can create high-quality and reliable construction materials that contribute to the safety, durability, and aesthetics of various construction projects.

- Q: How are steel coils used in the shipbuilding industry?

- Steel coils are used in the shipbuilding industry for various purposes such as constructing the ship's hull, decks, and other structural components. These coils are typically cut and shaped to form different sections, plates, or beams that are then welded together to create the ship's framework. Additionally, steel coils are also used for manufacturing equipment, machinery, and other components required for shipbuilding.

- Q: How are steel coils used in the manufacturing of cables?

- Steel coils are used in the manufacturing of cables as the core material around which the cable is wrapped. The high tensile strength of steel provides durability and stability, allowing the cable to withstand tension and pressure. The steel coils also help in preventing the cable from stretching or bending excessively, ensuring its structural integrity.

- Q: this is for a school project due morrow can u please answerwhat are disadvantages of stainless steelplease also show were u got info ty

- it sometimes rusts

- Q: Can steel coils be coated with zinc-nickel alloy?

- Yes, steel coils can be coated with zinc-nickel alloy. This coating provides excellent corrosion resistance and durability to the steel coils, making them suitable for various applications in industries such as automotive, construction, and manufacturing.

- Q: How are steel coils used in the manufacturing of marine equipment?

- Steel coils are used in the manufacturing of marine equipment as they provide the necessary strength and durability required for the construction of various components such as ship hulls, bulkheads, decks, and structural supports. These coils are typically used as raw material for cutting, shaping, and welding into the required shapes and sizes, ensuring the marine equipment can withstand the harsh conditions of the sea and maintain its structural integrity.

- Q: How do steel coils perform in corrosive environments?

- Steel coils typically perform well in corrosive environments due to their inherent resistance to corrosion. This is primarily because steel is an alloy composed of iron and other elements, such as carbon, which provides it with a protective layer known as a passive film. This passive film acts as a barrier between the steel surface and the corrosive elements, preventing direct contact and thus minimizing the risk of corrosion. In addition to the passive film, steel coils can also be coated with various protective coatings to enhance their resistance against corrosion. These coatings, such as zinc or epoxy, provide an additional layer of protection and further extend the lifespan of the steel coils when exposed to corrosive environments. However, it is important to note that the performance of steel coils in corrosive environments can still be influenced by factors such as the specific corrosive agent, exposure duration, and the presence of other contaminants. In highly aggressive environments, such as those with high humidity, saltwater exposure, or acidic chemicals, the protective layers on steel coils may deteriorate over time, leading to potential corrosion. To ensure optimal performance in corrosive environments, it is advisable to select steel coils with corrosion-resistant properties, such as stainless steel or galvanized steel. Regular maintenance and inspections are also crucial to identify any signs of corrosion early on and take appropriate measures to prevent further damage. Overall, steel coils offer good resistance to corrosion in most environments, but the severity of the corrosive conditions can ultimately impact their performance.

- Q: If rebar steel is welded together as opposed to 'tied' does it decrease the strength of the steel?

- The answer is it depends. I am not sure what steel alloy is used for rebar (there are hundreds of different steel alloys available commercially and different degrees of quality within any particular alloy and product form) but I assume it is a plain low carbon steel with a very simple heat treated condition. Welding does NOT increase the strength of steel, at least it does not in almost all cases (there are, of course, exceptions). A welded joint may be stronger than a tied joint but it depends on how the tied joint is tied and it depends on how the welded joint is welded. Crappy welds will not be as strong as well designed and executed tied joints. There are good reasons for different certifications for welders. With very little training and a little eye-hand coordination, anybody can learn to make farmer welds but sophisticated high quality welds in advanced steel alloys takes real skill, knowledge, and experience.

Send your message to us

HIGH QUALITY Galvanized Steel coils FOR YOUR

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords