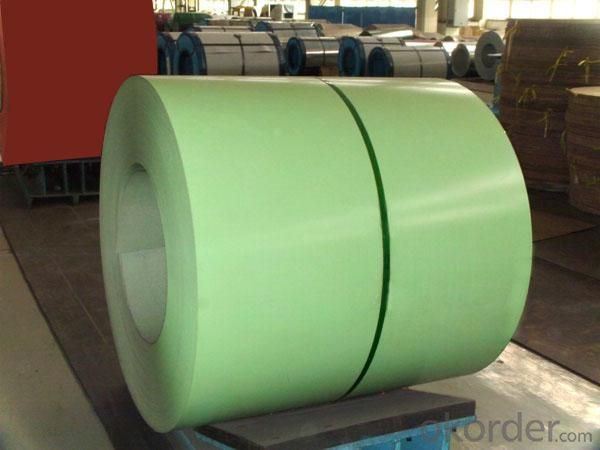

High Quality Steel Rolls Of Various Colors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.5

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Description:

Also called color steel roll, using advanced composite technology steel and bright color rich peritoneal highly fused into one, the good performance of both kinds of materials, greatly improve the chemical stability of the material, and has more effective anti rust and anti-corrosion performance. Color not only has the steel in flexibility, plasticity, pressure resistance, abrasion resistance, heat resistance and high temperature of excellent quality, also in terms of color, finish, feeling is also very prominent. It is worth mentioning is that all raw materials used in the production of color coated steel are non pollution and pollution-free environment-friendly materials and production process of the vast dust, whether it is production or use of the late have high environmental characteristics

2.Product characteristic:

1 light weight: 10-14 kg / square meter, equivalent to the brick wall of 1/30 2 insulation: core material heat conduction coefficient: <=0.041w/mk. 3 high strength: can be used for the construction of the ceiling of the bearing capacity of the bearing, bending resistance; general housing without beam column. 4 brightly colored: no surface decoration, color galvanized steel plate coating maintained at 10-15. 5 the installation is flexible and fast: the construction period can be shortened more than 40%

3.Application

Color steel plate with high mechanical strength, easy molding, and the performance of the coating materials, and the good performance of the coating materials and corrosion resistance. Color steel sheet is a new material which is highly praised in the world. By construction, home appliances, electrical and mechanical, transportation, interior decoration, office equipment and other industries.

Color steel plate with light, high strength, thermal insulation, beautiful and durable, and other advantages, is the construction and decoration of the integration of advanced construction installation. Color steel plate movable house construction is clean, widely used in large span workshop, warehouse, office buildings, villas, roof add layer, air purification room, cold storage, shops, kiosks and temporary housing. The weight of the square of the light colored steel sheet is lower than that of the 14KG, which can reduce the structural load and reduce the cost of the structure.

4.Reference pictures

- Q: So, i recently bought the game red steel 2 and i beat it, it was an amazing game! although since i had never played the first one ( i never knew about it actually) i had alot of questions like, why was he banished, where is his actual master, etc so i searched up on Youtube, red steel 1 to figure it all out and the games look nothing alike!! i mean the first one is like nothing but guns and the characters arnt the same ( well at least i dont think so) could someone explain why?

- Well, since Red Steel was one of the games that released when the Wii came out, initially people thought it was would be amazing and bought it on impulse since there wasn't a lot of options in the beginning. Turns out that the game was extremely horrible and no one liked it. So the company who made Red Steel (sorry, I forgot their name) wanted to take a totally different approach to their next game. That's why its all different. I haven't played either game so if there were any cliffhangers in the first game unfortunately you never know what happened.

- Q: What are the main factors that affect the corrosion resistance of steel coils?

- The main factors that affect the corrosion resistance of steel coils include the composition of the steel, the presence of impurities, the surface finish, the environmental conditions, and the protective coatings applied to the steel.

- Q: i cant find this stuff about steel:conductivitystrengthcorrosion resistancecommon applicationsif you know of any interesting facts, i could use those 2!thanx!

- The strength and corrosion resistance depends on the mix. Pure steel is pure iron plus 6% pure carbon. It is the carbon molecules that give it a tough crystallized strength. Pure iron is wrought iron and you can bend that with your hands. Strength also depends on the shape of the beam the most common steel beam is the W flange more commonly called the I beam. That is because the strength of the ‘I’ beam is just a little bit less than if the entire I beam was filled in; however the weight and material savings is huge. Steel itself has no corrosion resistance and is often given a zinc coating just to resist oxidization. Manganese, vanadium and tungsten are just some of the other elements added to improve the steel.

- Q: How are steel coils used in the manufacturing of agricultural trailers?

- Steel coils are used in the manufacturing of agricultural trailers to provide strength, durability, and stability to the trailer's frame, ensuring it can withstand heavy loads and harsh working conditions. These coils are typically shaped and welded to create the trailer's structural components, such as the chassis, sidewalls, and flooring. Additionally, steel coils can be cut and formed into various parts, including axles, suspension systems, and hitch assemblies, to further enhance the trailer's performance and functionality in agricultural operations.

- Q: How are steel coils processed before they are used in manufacturing?

- Before being used in manufacturing, steel coils undergo several processing steps. The initial step, known as pickling, entails immersing the coils in an acid bath to eliminate any surface impurities such as rust or scale. This step serves to enhance the surface quality of the steel. After pickling, the coils are subjected to a process called cold rolling. This involves passing the coils through a set of rollers to decrease their thickness and enhance their dimensional accuracy. Additionally, cold rolling enhances the mechanical properties of the steel, rendering it stronger and more durable. Following cold rolling, the coils are annealed. This process involves heating the coils to a specific temperature and gradually cooling them. Annealing helps to alleviate internal stresses within the steel and improve its formability and ductility. Subsequently, the coils may undergo further surface treatments, such as galvanizing or coating. Galvanizing involves applying a layer of zinc to protect the steel from corrosion, while coating may involve applying various types of paint or polymer to enhance the steel's appearance or provide specific functionalities. Once the coils have undergone the necessary processing and treatments, they are typically cut into smaller sheets or strips according to the manufacturing requirements. These sheets or strips can then be utilized in various manufacturing processes, including stamping, forming, welding, or fabrication, to create a diverse array of products, ranging from automotive components to appliances, construction materials, and more. In summary, steel coils go through a series of processing steps, including pickling, cold rolling, annealing, and surface treatments, before they are prepared for use in manufacturing. These processes result in improved quality, strength, and formability of the steel, enabling it to be transformed into a wide range of products.

- Q: How do steel coils perform in corrosive environments?

- Steel coils perform well in corrosive environments due to their inherent resistance to corrosion. The protective layer of oxide on the surface of steel, along with the addition of corrosion-resistant coatings, helps prevent the coils from rusting or corroding when exposed to moisture or chemicals. This makes steel coils ideal for various applications in corrosive environments, such as transportation, construction, and manufacturing industries.

- Q: I am looking for steel. I need a lot.

- ..mm where are you located? .. how much steel is a lot of steel to you? .. whats it worth to you? .. do ya want it from salvage sorce, or from milled sorces? There is a lot of it around, even places that would pay ya to haul it off..

- Q: We all know that when we drop a small steel ball (size 3mm diameter; weight 1.10 grams) and a paper (size 11.7 inches length and 8.3 inches breadth; weight 4.5 grams) from a height. The steel ball will win the race to the ground due to its aerodynamic structure.Now imagine the same steel ball with the same weight converted to the structure similar that of paper. What will be the result? Which object will fall first; steel sheet or paper?

- The 2 objects will have the same size and shape. Therefore they will have the same air resistance. So the heavier object (the sheet of paper) will reach the ground first.

- Q: Is it possible to make a homemade blacksmith forge from a washing machine drum made of stainless steel?

- This Site Might Help You. RE: Can I make a homemade blacksmith forge from an old stainless steel washing machine drum? Is it possible to make a homemade blacksmith forge from a washing machine drum made of stainless steel?

- Q: No. Not Stainless steel, I mean STEEL.Not a specific type, but STEEL.Thanks. xo

- Steel is mostly iron. However, it is an alloy or solid solution, or mixture of iron and other metals or sometimes carbon. All steel is a mixture. there are many varieties.

Send your message to us

High Quality Steel Rolls Of Various Colors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.5

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords