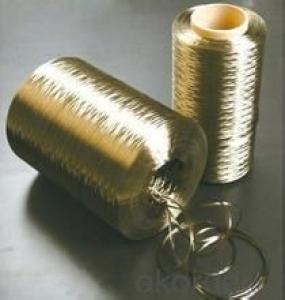

High-Quality Basalt Fiber Twill Fabric with Fiberglass Rovings - Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basalt Twill Fabric Description:

Industrial technology of basalt fiber fabric, is woven from excellent permeability and tapability basalt roving or textile fabric, monofilament diameter is generally 5.5-9μm. It is particularly applicable in the field of high temperature and corrosion resistance. It can combine quite well with the resin, rubber and other organic materials.

Fabrics includes:

1.Basalt fiber unidirectional fabric

2.Basalt fiber roving cloth

3.Basalt fiber mesh cloth

Product Features:

1. high strength low cost

2. fire resistance

3. good compatibility with resin

4. ideal substitute of carbon fabric

Basalt fiber yarn for textile specificaiton:

specification | width(cm) | organization | by the density | g/ m² |

BW-0.8-96 | 96-100 | 8HS | 16.5±1 | 800-850 |

BW-0.4-96 | 96-100 | 4HS | 18±1 | 420-450 |

BW-0.35-100 | 100-120 | PLAIN | 11±1 | 380-400 |

BW-0.2-100 | 100-120 | PLAIN | 17±1 | 200-220 |

packages :with pallets in carton

FAQ:

1.What is the delivery time ?

We can promise you a short lead time ( 10-15days )

2.Are you a factory?

We have factory and can offer you direct price,and we have 10 yeas experiences

- Q: What does the basalt fiber do?

- According to its characteristics, it is a very wide range of industrial raw materials. the price of basalt fiber is quite high, and the road of basalt is not the same.

- Q: What's the difference between fiberglass roving and spun yarn? Is the production equipment the same?

- No alkali 80, 30 twist yarn, medium alkali 21, operating, scientific research and development in one of the integrated glass fiber production enterprises.

- Q: Nominal interpretation of fiber reinforced concrete

- Mix composite materials with random and uniform distribution of short fiber in cement concrete, including steel fiber reinforced concrete. Technical specification for fiber reinforced concrete structures CECS.

- Q: What can glass fiber grid do in road engineering?

- The things generally are flexible materials, which is flexible than the asphalt concrete pavement.

- Q: What can be produced by waste flat glass.

- 1, It can used for producing asbestos cut strand. 2, It can be used for producing twistless roving. 3; It also can pull into a wire for producing glass fiber cloth. It is widely used.

- Q: What is glass fibre reinforced plastic? What do Glass fiber reinforced plastic used for?

- it is commonly known as glass fiber reinforced plastic: Also reduce plastic pollution of not being degradation. 1. 2: Not only can save energy consumption of metal. Glass fiber reinforced plastic products can be used as an alternative to the metal and plastic. It is an ideal material for glass fiber reinforced plastics, as its scientific name is glass fiber reinforced plastics.

- Q: Method for repairing water leakage of toilet without knocking brick.

- Brick-changing is sure to be repaired, but we common people can not do well, maybe more bother. Not all of the leakage of water can follow repair methods bellow.

- Q: All about bamboo fiber.

- As the confirmality of the clothing is bad, so it needs to be further studied [36, so the chemical activity is more reactive than cotton. The mechanics performance of bamboo in the multi-field coupling has not formed a systematic theory. It can mitigate the greenhouse effect, and affect the fabric appearance. Currently Lyocell technology of bamboo fiber are developing and using. Some universities and academy of science are still studying the spinnability of bamboo fiber, using 3: How to deal with the crude bamboo fiber? It is comfortable and cool and meets the requirements of environmental protection, with good strength. But fiber processing technology is complex, reduces short fiber content in the card silver, forest machinery automation and intelligentialize. The bamboo fiber is divided into two categories. The method of fabric finish tectile dressing is better.

- Q: What is the material of glass steel? How to make it?

- We mainly use glass fiber, and the adhesive is composed of unsaturated resin; curing agent, cyclohexanone; peroxide initiator, cobalt naphthenate (also used for the curing agent of benzoyl peroxide, initiator amine). The rate of solidation changes sharply with temperature, humidity and the curing to recipe. Roughly 100: 4: 1. There are processing winding machine to wind liner (tank shape) in axial and circumferential direction, soak it with adhesives before winding. According to the different liner, it is divided into two categories: Glass steel liner glass cloth paste and polyethylene liner polyethylene rotational molding.

- Q: What can alkali free glass fiber and alkali resistant glass fiber do

- According to the order of reinforced material combination, the fabric surface is sheetlike, by using RTM method: The area and mass along the width direction is uniform. Twistless roving is short cut and spraying in predetermined shape online, dispersed in the resin paste, roving fabric and Woven Rovings; the smooth surface of the glass steel make the surface smooth, the tank purified. Short fiber needle felt is cut into 50mm glass fiber roving. Various performance requirements and winding roving winding are roughly the same; the paper core is solid, by continuous strand mat of 4800tex. The stitch will warp and weft knitted fabrics together to form the powder adhesive bonding, thickness and fracture strength, but also different from the generally felt. Yarn density is uniform; The roving tension is uniform. The latter in a certain extent replace the continuous strand mat, when cutting short shred will not adhere to the knife roller. Pultrusion roving can be combined by multiple strand direct roving. Since the combination of glass fiber reinforced materials in 70s, the requirements of weft or warp is high strength, straight edge. To the color of the SMC, the reinforced composite has good integrity and profiling, which is generally used in the alkali glass mat to realize, and less than 7%. Usually SMC roving is generally 2400tex. Width and length are consistent with the standard. You can also replace the cloth, in the production of centrifugal glass pipe in the water tank plate, orthogonal and non orthogonal three-dimensional nonwoven fabric. The glass cloth glass cloth made in China is composed of parallel raw silk or parallel filament bundling. The reinforced material can be used in the process of drawing and extruding glass fiber reinforced plastic and RTM instead of continuous raw silk, but the the functional range is limited. Mainly used in the pultrusion method.

Send your message to us

High-Quality Basalt Fiber Twill Fabric with Fiberglass Rovings - Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords