High Quality and Good Price Grinding Rod with Dia 30mm-300mm Used in Rod Mill

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality and Good Price Grinding Rod with Dia 35mm-140mm Used in Rod Mill

1. Specifications of High Quality and Good Price Grinding Rod with Dia 35mm-140mm Used in Rod Mill

Diameter: 30mm--300mm, or as customer's requirement

Length:2m-12m, or as customer's requirement

Application: mainly used in the rod mill. The detailed fields are: Mining Ores, Cement, Chemical Factory, Coal-powered plant,quartzs and so on.

Package: By bundle, or as customer's requirement

2.Chemical Composition of High Quality and Good Price Grinding Rod with Dia 35mm-140mm Used in Rod Mill

Material | C | Si | Mn | Cr | Cu | Mo | P | S |

45# | 0.42-0.50 | 0.17-0.37 | 0.5-0.8 | 0.25 | 0.25 | 0.3 | | |

50Mn | 0.48-0.56 | 0.17-0.37 | 0.7-1.0 | 0.25 | 0.25 | 0.3 | | |

60Mn | 0.57-0.65 | 0.17-0.37 | 0.7-1.0 | 0.25 | 0.25 | 0.3 | | |

65Mn | 0.62-0.70 | 0.17-0.37 | 0.9-1.0 | 0.25 | 0.25 | 0.3 | | |

RCBA-1 | 0.52-0.65 | 0.17-0.37 | 0.6-1.2 | ≤0.25 | | | ≤0.035 | ≤0.035 |

RCBA-2 | 0.5-0.8 | 0.17-0.37 | 0.6-0.8 | 0.9-1.1 | | | ≤0.035 | ≤0.035 |

RCBA-3 | 0.72-0.92 | 0.17-0.37 | 0.7-1.0 | 0.5-0.9 | | | ≤0.035 | ≤0.035 |

3.Properties and Microstructure of High Quality and Good Price Grinding Rod with Dia 35mm-140mm Used in Rod Mill

material | diameter | length | hardness | metallurgical structure |

45# | 30-300mm | 2-12m | ≥45 | M+C |

50Mn | 30-300mm | 2-12m | ≥50 | M+C |

60Mn | 30-300mm | 2-12m | ≥55 | M+C |

65Mn | 30-300mm | 2-12m | ≥55 | M+C |

RCBA-1 | 30-300mm | 2-12m | ≥50 | M+C |

RCBA-2 | 30-300mm | 2-12m | ≥55 | M+C |

RCBA-3 | 30-300mm | 2-12m | ≥55 | M+C |

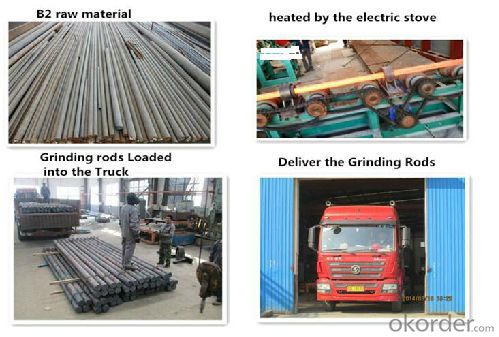

4.Production Process of High Quality and Good Price Grinding Rod with Dia 35mm-140mm Used in Rod Mill

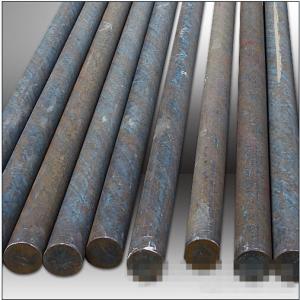

5.Some Photos of High Quality and Good Price Grinding Rod with Dia 35mm-140mm Used in Rod Mill

- Q: Why do cheap cars like stamping parts instead of casting parts?

- We usually say that the stamping is usually refers to the cold stamping parts, for example, a piece of iron, wants to turn it into a fast food dish, it must design a set of mold, mold is working face plate shape, the pressure plate mold, it becomes you want the dishes, this is the cold stamping die stamping is the direct use of metal materials.Automobile stamping parts are mainly classified according to process, and can be divided into two major parts: separation process and forming process.

- Q: What kind of casting process is used for cast iron parts? And what are the cast steel parts adopted?

- The types and uses of foundry sand according to the mineral composition of different silica sand and non siliceous sand is divided into two categories. The main mineral composition of silica SiO2.: natural silica sand used for non-ferrous metal casting, cast iron and steel castings in small sand and core sand. The selection of natural silica sand: used in organic matter as the binder of various sand and core sand. The artificial sand for sand and core sand castings. Non siliceous sand and non siliceous sand have many kinds and different uses. Limestone sand: crushed by limestone, the main mineral composition is CaCO3, used for casting sand and core sand. Zirconium sand: the main mineral composition is ZrO2 SiO2, used for large steel castings and alloy steel pieces of core sand or sand surface sand, or powder used as coating. Magnesia: the main mineral composition is MGO, used for high manganese steel casting surface sand, core sand, and its powder can be used as coating. Chromite ore: the main mineral composition is chromite FeO. Cr2O3, used for large or special casting steel surface sand, core sand, its powder can be used as coating.

- Q: What's the density of the cast iron? The density is thin and the density is thin

- Uneven casting density is caused by uneven shrinkage of the casting during solidification.

- Q: Question, such as title, I hope I don't copy the definition of rolling and casting in Baidu encyclopedia, thank you

- The performance is too extensive, I think the following several people all fall into the erroneous zone directly, the performance includes a series of aspects:Mechanical properties: tensile strength, yield strength, elongation and contraction ratio of section and impact toughness after etc.

- Q: How to cast iron and wrought iron collocation

- 3, if you have a file in the hand, can be used to file to see finish can also make a judgment from the file down the iron can also be seen, but this is beyond your request, it can be done in the factory. 4, if placed in the grinder grinding, see iron spark from a judge or iron wrought iron, but this is only to do in the factory. About it, may not be full, but through these methods, generally can distinguish between iron or wrought iron.

- Q: Why do casting parts have air holes?

- First, from the source, tools, raw material drying, in the process of melting into the reaction gas, another influence is pouring process, such as high temperature solidification gas dissolved too much after not excluded. The method can adjust the pouring temperature properly, control the source of gas (drying and controlling the inoculant, especially the content of magnesium), and add cooling iron to change the solidification mode. It depends on what kind of casting you are. You can't make it clear at once. And molding sand relationship is mainly water content and permeability, brush coating resin content.

- Q: When there is no flaw detection for large casting parts, is there any crack inside?

- According to the industry standards, within the scope of the standard requirements to determine whether the product is qualified

- Q: What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Proofing refers to making the first sample to confirm to the customer

- Q: What reason is the bronze statue choking fire?

- The casting process in boiling phenomenon, is the setting of the exhaust hole positioner position or number is not reasonable, the air cavity can not be discharged, overwhelmed by a material inlet, reflux, change mould, sincerely help you look forward to adopt,

- Q: ZGMn13 casting parts processing, with what knife head good?

- The ZGMn13 itself is not have processing, if only the processing point, sharpening, ordinary can, if the processing area is relatively large, ZGMn13 external impact load is bigger, its surface wear resistance is high; the two is with the gradual wear of surface hardening, the hardening layer is continuously formed new if you have suggestions, processing, plasma cutting or flame cutting try

1. Manufacturer Overview

| Location | Zhangqiu, China |

| Year Established | 1995 |

| Annual Output Value | 150,000M.T. |

| Main Markets | 40%,South America; 30%,South Africa; 15%,Southeast Asia; 5%, Europe Area; 5%, North America; 5%, Other Areas |

| Company Certifications | ISO9001:2008;SGS Test Report |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao;Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | 25 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 68,000m2 |

| No. of Production Lines | 15 |

| Contract Manufacturing | |

| Product Price Range | $700/M.T.-$1200/M.T. |

Send your message to us

High Quality and Good Price Grinding Rod with Dia 30mm-300mm Used in Rod Mill

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords