High Quality Aluminum Veneer Sheets - Color Coated Embossed Aluminum

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

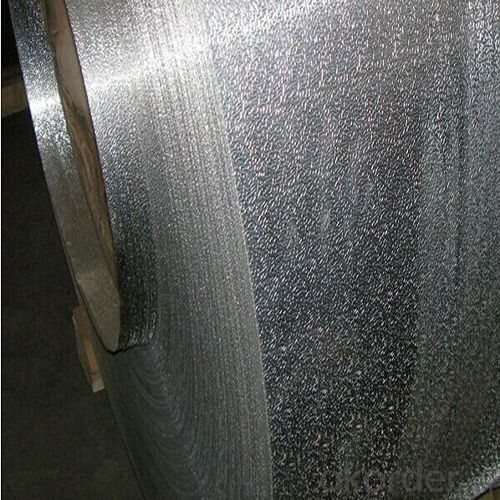

1.Structure of Color Coated Aluminum Embossed Sheet Description:

Color Coated Aluminum Embossed Sheet are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on。Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Color Coated Aluminum Embossed Sheet:

Coating Thickness: 0.01mm-0.15mm, 0.02mm0.025mm

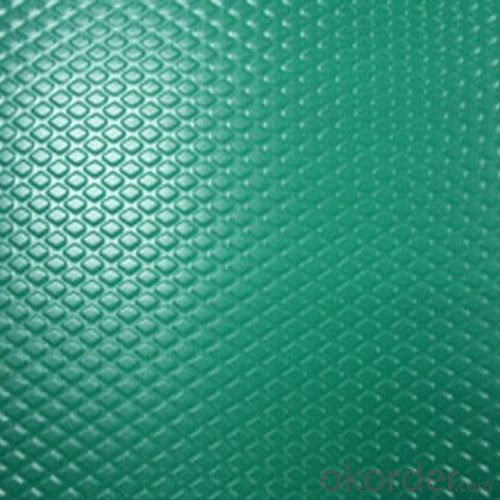

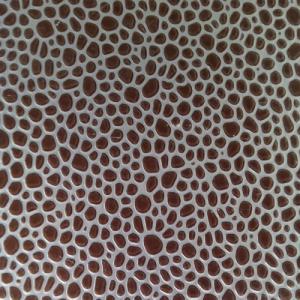

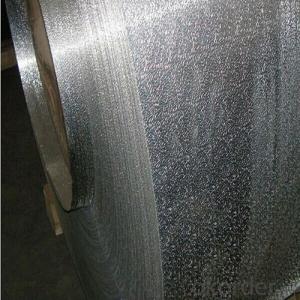

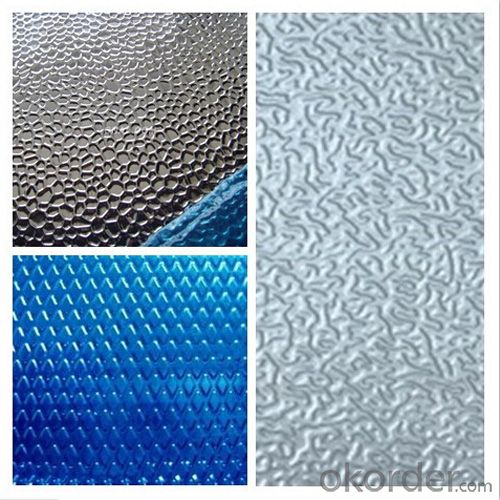

Surface Treatment: Color Coated, Embossed

Coating Color: Red, Green, Blue, etc

Coating: PE/PVDF

Surface: One Side Bright, Two Sides Brigh

3. Color Coated Aluminum Embossed Sheet Images:

4. Color Coated Aluminum Embossed Sheet Specification:

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Ti | Al |

| 1060 | 0.2 | 0.25 | 0.05 | 0.03 | 0.03 | 0.05 | 0.015-0.02 | 99.6 |

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | 0.05 | 0.015-0.02 | 99.5 |

| 1100 | 0.2 | 0.5-0.6 | 0.05 | 0.05 | - | 0.05 | 0.015-0.02 | 99.0 |

| 1235 | 0.65 | 0.05 | 0.05 | 0.05 | 0.1 | 0.06 | 99.35 | |

| 3003 | 0.2 | 0.3-0.45 | 0.05-0.15 | 1.05-1.35 | - | 0.10 | - | - |

| 3102 | 0.2 | 0.1-0.4 | <0.1 | 0.1-0.4 | - | <0.05 | <0.05 | - |

| 3105 | 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.4 | 0.1 | - |

| 5052 | 0.088 | 0.296 | 0.007 | 0.038 | 2.253 | 0.009 | 0.012 | - |

| 8011 | 0.55-0.59 | 0.69-0.75 | 0.02 | 0.025 | 0.01 | 0.01 | 0.015-0.02 | - |

| 5083 | </=0.4 | 0.4 | </=0.1 | 0.4-1.0 | 4.0-4.9 | 0.25 | </=0.15 | R |

| 5754 | 0.07 | 0.3 | 0.006 | 0.18 | - | - | 0.016 | R |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.25 | 0.15 | R |

| 6082 | 0.8-1.5 | 0.5 | 0.1 | 0.4-1.0 | 0.6-1.2 | 0.2 | 0.1 | R |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: How are aluminum sheets different from aluminum plates?

- Aluminum sheets and aluminum plates differ primarily in terms of thickness and applications. Aluminum sheets are typically thinner, ranging from 0.2mm to 6mm in thickness, whereas aluminum plates are thicker, usually starting from 6mm and going up to several inches thick. Aluminum sheets are commonly used for general purposes such as packaging, signage, and roofing due to their lightweight nature and flexibility. They are often bent, formed, and cut into various shapes and sizes to fulfill specific requirements. On the other hand, aluminum plates are typically used in applications that require higher strength and durability. With their greater thickness, they provide enhanced structural integrity and are commonly utilized in industries such as aerospace, automotive, and construction. Aluminum plates can withstand heavy loads and are often used as structural components in buildings, aircraft, and machinery. In summary, the main differences between aluminum sheets and aluminum plates lie in their thickness and the specific applications they are suited for. Sheets are thinner and more flexible, suitable for general purposes, while plates are thicker and stronger, ideal for heavy-duty applications that require structural integrity.

- Q: What are the different methods of surface cleaning for aluminum sheets?

- Aluminum sheets can be cleaned using various methods, each with its own advantages and suitability for different cleaning needs. One method is mechanical cleaning, which involves using techniques like brushes, abrasive pads, sandpaper, or a wire brush to remove dirt, stains, and oxidation from the surface. However, caution must be taken to avoid scratching the surface. Chemical cleaning, on the other hand, utilizes specific cleaning agents or solutions designed to dissolve or remove dirt, grease, oil, or other contaminants from aluminum surfaces. The choice of cleaning agent depends on the type of dirt or stain to be removed. High-pressure water cleaning is a method that employs a strong water jet to dislodge dirt or grime from the aluminum surface. It works well for removing loose debris or light dirt from larger areas, but may not be effective for heavily soiled surfaces. Steam cleaning involves using high-temperature steam to loosen dirt, grime, or other contaminants, making them easier to wipe or rinse away. It is versatile and suitable for both small and large surfaces. Another specialized method is electrolytic cleaning, which uses an electric current to remove contaminants. The aluminum sheet is immersed in a cleaning solution, and the electric current attracts the contaminants to a sacrificial electrode, leaving the sheet clean. However, this method requires specialized equipment and expertise. When choosing the appropriate cleaning method, it is important to consider the specific requirements, condition of the sheet, and desired level of cleanliness. Testing the chosen method on a small, inconspicuous area is also advisable to avoid potential damage.

- Q: Solid aluminum or solid wooden boxes-no glass top. Would glass make the temperature rise more quickly? (ie Solar)? Thanks.Joseph

- Aluminum is a very good conductor of heat and wood is a very poor conductor of heat. If the heat source is inside the box with the food, it will heat quicker in a wooden box. If the heat source is outside the box it will heat quicker in an aluminum box. Having a glass top would be equivalent to having the heat inside the box so a wood box with a glass top will make a better solar heater.

- Q: What is the classification of 6061106070 aluminum plate, which respectively represent what it means to ask God for help

- Three, the beginning of the aluminum manganese alloy, 3003, 3004, 3015 and so on, the use of a wide range, also known as rust aluminum. Four, the beginning of the four Department of aluminum is aluminum silicon alloy, on behalf of 4A01 five, the beginning of the aluminum magnesium alloy, there are 5052, 5083 and so on, the use of more than three series, the domestic manufacturers can do.

- Q: What are the acoustic properties of aluminum sheets?

- Various applications benefit from the acoustic properties possessed by aluminum sheets. One key property is their lightweight composition, resulting in a high strength-to-weight ratio. This characteristic enables aluminum sheets to vibrate easily upon impact, facilitating sound transmission. Furthermore, their low density allows for sound energy absorption and noise level reduction. In addition, aluminum sheets boast exceptional corrosion resistance, ensuring their durability and longevity in diverse environments. This attribute proves particularly crucial in applications where long-term acoustic performance is essential, such as in the construction or automotive industries. Moreover, aluminum displays excellent thermal conductivity, facilitating efficient heat dissipation. This quality proves advantageous in scenarios where effective dispersal of heat generated by sound sources is necessary to prevent material damage or degradation. In conclusion, the acoustic properties of aluminum sheets, encompassing their lightweight nature, sound transmission capabilities, noise reduction effectiveness, corrosion resistance, and thermal conductivity, establish them as a versatile and dependable choice for a wide range of acoustic applications.

- Q: What are the physical properties of aluminum?

- Some physical properties of aluminum include its silvery-white appearance, low density, high thermal conductivity, and good electrical conductivity. It has a melting point of 660.32°C (1220.58°F) and a boiling point of 2519°C (4566°F). Aluminum is also malleable, ductile, and highly corrosion resistant.

- Q: What is the melting point of 101 aluminum sheets?

- Approximately 660 degrees Celsius or 1220 degrees Fahrenheit is the melting point of 101 aluminum sheets.

- Q: Can aluminum sheets be used for aircraft manufacturing?

- Yes, aluminum sheets are commonly used for aircraft manufacturing. Aluminum is a lightweight and corrosion-resistant material, making it an ideal choice for constructing various components of an aircraft. It is strong enough to withstand the stresses and strains experienced during flight, while also being malleable enough to be formed into various shapes and sizes. Additionally, aluminum sheets can be easily joined together using various welding techniques, allowing for efficient and effective assembly of aircraft structures. Overall, the use of aluminum sheets in aircraft manufacturing helps to ensure a balance between strength, weight, and durability, making it a preferred material in the aerospace industry.

- Q: I don't know if the electrons are being passed from my hand to the aluminum or from the aluminum to my hand.Thanks

- Aluminum is a metal and every metal has a property that it holds electrons of its outer most orbital quite loosely ( it is electropositive ). And our hand's skin consists of mostly COVALENT bonded compounds which hold their electrons quite tightly. So if we touch aluminum the chances are strong that the electrons are being transferred from aluminum to our hands. But since our hand have covalent compounds so the total transfer must be very small if it is anyway. Otherwise we feel shock every time we touch a neutral aluminum also IF U develop some negative charge then aluminum will take that charge since it has small hold on the outermost electrons. so it easily takes charge frm yr hand at lower potential to its ground potential surface.

- Q: What is the typical fracture toughness of aluminum sheets?

- The fracture toughness of aluminum sheets can vary depending on several factors, such as the composition of the alloy, the heat treatment, and the manufacturing process. On average, the fracture toughness of aluminum sheets ranges from 20 to 40 MPa√m. This value reflects how well the material can resist crack propagation and withstand applied loads without breaking. It's important to note that the fracture toughness of aluminum alloys can be improved through techniques like adding alloying elements and refining the grain structure. Therefore, when considering the fracture toughness of aluminum sheets for a specific application, it's crucial to take into account the specific alloy and its processing conditions.

Send your message to us

High Quality Aluminum Veneer Sheets - Color Coated Embossed Aluminum

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords