High Quality Aluminum Alloy Sheet Manufactory 2024

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Manufactory 2024 Aluminium Alloy Sheet Description:

T6 Alloy Aluminum Plate 7022 adds to the 3%-7.5% of zinc-containing alloys of magnesium, can form the strengthening effect of MgZn2, make the alloy heat treatment effect than on the aluminum-zinc alloy. Improve the content of zinc and magnesium alloys, the tensile strength will be further improved, but its resistance to stress corrosion and spalling corrosion will decline. Subjected to heat treatment and can reach very high strength characteristics. 7022 material is generally a small amount of copper, chrome, alloy, the 7022 aluminum alloy is the top grade, known as the most excellent products in aluminum alloy, high strength, far better than any mild steel.

2.Main Features of Manufactory 2024 Aluminium Alloy Sheet:

PVC Protect Film

Waterproof paper

High Quality

Competitive Price

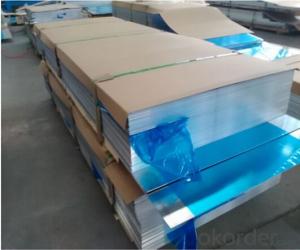

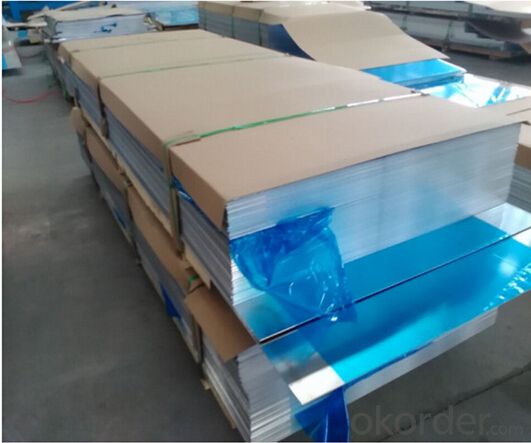

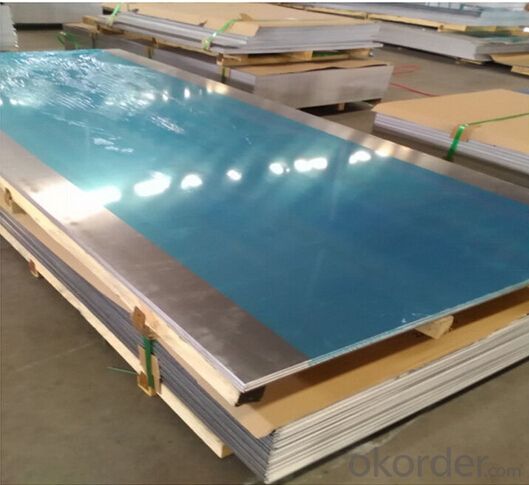

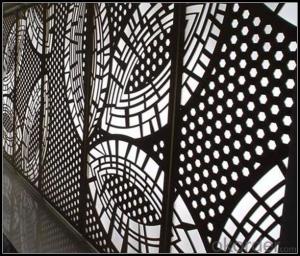

3. Manufactory 2024 Aluminium Alloy Sheet Images:

4. Manufactory 2024 Aluminium Alloy Sheet Specification:

Commodity | manufactory 2024 Aluminium alloy Sheet |

Material |

1050,1060,1100,2024,2204,2A16(LY16),2A06(LY6),3003,3004,5052, 5005,5083,6061,6063 |

Finish (Surface) |

Hairline Finish,Mirror Finish,Oxidation Finish,PS Finish,Embossed Finish |

Thickness |

0.15mm~200mm |

Width |

10mm~2500mm |

Length |

2000mm~2500mm |

Application |

Aluminium Sheet can apply to Lighting,solar reflective film,building

appearance,interior decorating:Ceilings,walls, furniture,cabinets,elevators, signs,

nameplates,bags,automotive interior and exterior decoration Upholstery:Photo

Frame;household appliances:refrigerators,microwave ovens,audio equipment,etc.

aerospace and military aspects, such as China's large aircraft manufacturing,the

Shenzhou spacecraft series,satellite.the mechanical parts processing,mold

making,chemical/thermal insulation pipes coated. |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: This question asks for various applications of recycled aluminum other than its traditional uses.

- <p>Recycled aluminum has a wide range of alternative uses. It can be used in the manufacturing of new aluminum products, reducing the need for raw materials. It's also used in construction for window frames, doors, and roofing. In the automotive industry, recycled aluminum is used for car parts, helping to reduce vehicle weight and improve fuel efficiency. Additionally, it's utilized in the aerospace industry for lightweight aircraft components. Recycled aluminum is also found in everyday items like cans, foil, and packaging materials. Furthermore, it's used in electrical components due to its excellent conductivity, and in the production of bicycles and sports equipment for its strength and lightweight properties.</p>

- Q: What measures should be taken to ensure safety when handling or using aluminum products?

- <p>When using aluminum products, safety precautions include handling with care to avoid sharp edges that may cause cuts. Ensure proper ventilation when working with aluminum powder or dust to prevent respiratory issues or fire hazards. Avoid using aluminum cookware for acidic or alkaline foods as it can react and leach aluminum into the food. Always follow the manufacturer's instructions for use and cleaning, and wear appropriate protective gear such as gloves and masks when necessary.</p>

- Q: Is it possible to utilize aluminum to enhance the durability and efficiency of batteries?

- <p>Yes, aluminum can be used to make batteries more durable and efficient. Aluminum's lightweight, high conductivity, and corrosion resistance make it a favorable material for battery components. In particular, aluminum-air batteries leverage aluminum's ability to provide a high energy density. Additionally, research is ongoing to improve lithium-ion batteries by using aluminum as a component in the anode, which can potentially increase energy storage capacity and lifespan. However, challenges such as aluminum's reactivity and the development of efficient recycling methods must be addressed for widespread adoption in battery technology.</p>

- Q: This question asks for methods to prevent aluminum from seeping into food when cooking with aluminum cookware.

- <p>To prevent aluminum from leaching into food when using aluminum cookware, follow these guidelines: Avoid using aluminum cookware for acidic foods or beverages, as acids can cause aluminum to leach. Do not cook with high heat, as this can increase the risk of leaching. Use a protective coating, such as a non-stick coating or a thin layer of oil, to create a barrier between the food and the aluminum. Regularly replace or repair any damaged cookware to prevent exposure to bare aluminum. Finally, consider using alternative cookware materials, such as stainless steel or cast iron, for long-term cooking and storage.</p>

- Q: This question asks about the methods to determine the safety of a specific brand's aluminum products.

- <p>To determine if a particular brand of aluminum products is safe to use, one should look for certifications and standards compliance. Check if the brand has certifications such as ISO 9001 for quality management systems or specific safety certifications relevant to aluminum products. Look for compliance with safety standards like ANSI, ASTM, or EN standards. Additionally, research customer reviews and testimonials, and consider third-party lab testing results. It's also important to inquire about the manufacturing process to ensure it adheres to environmental and health safety regulations. Lastly, consult with industry experts or regulatory bodies for their assessment of the brand's safety practices.</p>

- Q: This question asks for examples of industrial processes that incorporate the use of aluminum.

- <p>Aluminum is widely used in various industrial processes due to its lightweight, corrosion resistance, and high strength-to-weight ratio. Some key industrial processes that utilize aluminum include the automotive industry for manufacturing car parts, the aerospace industry for aircraft construction, the construction industry for building materials, the packaging industry for food and beverage cans, and the electronics industry for components in devices. Aluminum is also used in the manufacturing of machinery, electrical equipment, and transportation equipment. Its versatility makes it a crucial material in many industrial applications.</p>

- Q: This question asks about the impact of adding tin to aluminum alloys on their characteristics and longevity.

- <p>Adding tin to aluminum alloys can significantly alter their properties and durability. Tin enhances the alloy's strength, hardness, and resistance to wear, making it suitable for applications requiring high mechanical properties. It also improves the alloy's corrosion resistance, particularly in marine environments. However, the addition of tin can reduce the alloy's ductility and formability, which might limit its use in certain applications that require extensive shaping or bending. The overall durability of the alloy is improved due to the increased resistance to environmental factors, but it's essential to balance the alloy composition to optimize its properties for specific applications.</p>

- Q: This question asks for an explanation of the process involved in the production of aluminum foil.

- <p>Aluminum foil is made through a process that starts with the extraction of aluminum from its ore, bauxite. The bauxite is refined to produce aluminum oxide, which is then reduced to aluminum using the Hall-H茅roult process. The aluminum is then melted and cast into large ingots. These ingots are heated and rolled into thin sheets using large industrial rolling mills. The aluminum is rolled multiple times, each pass reducing its thickness until it reaches the desired foil thickness. The final thin sheets are then cut and packaged as aluminum foil. This process requires precision and control to ensure the foil is uniform and free of defects.</p>

- Q: Is it safe and effective to use aluminum foil for wrapping food items in a refrigerator or freezer?

- <p>Yes, you can use aluminum foil to wrap food in a refrigerator or freezer. Aluminum foil is a good insulator and can help keep food fresh by preventing freezer burn and moisture loss. It also protects food from absorbing odors. However, it's important to ensure the foil is tightly wrapped around the food to maintain its effectiveness. Additionally, avoid using aluminum foil with acidic foods as it can react with them, potentially causing a metallic taste.</p>

- Q: Explain how aluminum influences the synthesis and function of neurotransmitters.

- <p>Aluminum has been suggested to affect the production of neurotransmitters by potentially disrupting the normal functioning of enzymes and receptors involved in neurotransmitter synthesis and release. It may interfere with the uptake of essential metals like magnesium and zinc, which are crucial for the proper functioning of neurotransmitter systems. Aluminum can also alter the permeability of cell membranes, affecting the transport of neurotransmitters across the synaptic cleft. Additionally, there is evidence that aluminum may contribute to oxidative stress, which can impair the synthesis and function of neurotransmitters. However, it's important to note that the exact mechanisms are not fully understood, and more research is needed to establish a definitive link between aluminum exposure and neurotransmitter dysfunction.</p>

Send your message to us

High Quality Aluminum Alloy Sheet Manufactory 2024

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords