High Quality 201 Stainless Steel Coil for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Basic Info.

Model NO.:201

Surface Treatment:2b, Ba, No. 1, No. 8, 8k, Mirror

Technique:Hot Rolled and Cold Rolled

Standard:ASTM, JIS, GB, AISI, DIN, BS

Steel Grade:200

Thickness:0.3mm-30mm

Width:1000 to 2000mm or Customized

Certifications:ISO 9001 and SGS

Export Markets:Global

Additional Info.

Packing:Seaworthy Wooden Pallet or Customized

Standard:SGS

Origin:Taiyuan Shanghai

Production Capacity:10000tons/Month

Product Description

1.Specifications of Stainless Steel Coil:

Width: 1000 to 2000mm or customized

Thickness: 0.3 to 30mm

Standards: AISI, ASTM, JIS, SUS and GB

Grade: 200/300/400 series

Surface: 2b, Ba, No. 1, No. 8, 8k etc.

Certifications: ISO 9001 and SGS

Applications: Kitchenware, utensils, tableware, household appliances, construction decoration and daily products

Packing: Seaworthy wooden pallet or according to client's requirement

Place of origin: Shanxi China (mainland)

Payment terms: L/C or T/T

Delivery time: Up to order quantity

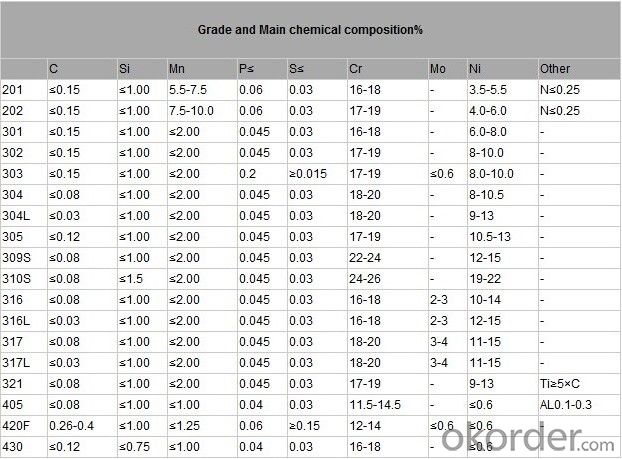

2.Chemical Composition

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q: How are steel coils processed for slitting or edge trimming?

- Steel coils are processed for slitting or edge trimming by feeding the coil into a slitting or trimming machine. The machine uses sharp rotating blades to cut the coil into smaller strips or remove the excess material from the edges. This process helps to create narrower coils or achieve precise edge dimensions for various applications.

- Q: What is the role of steel coils in the manufacturing of agricultural machinery?

- Steel coils are essential in the manufacturing of agricultural machinery as they are used to form various components such as frames, chassis, and structural supports. These coils provide the necessary strength, durability, and rigidity required to withstand the demanding conditions and heavy workload typically encountered in the agricultural sector.

- Q: Is it possible to have a 25 room Hotel building with Steel structure. Thay is instead of traditional RCC can we have a 25 room hotel constructed using steel construction? Is it economic and how much time will it take to construct the same? Appraximate area would be 5000sq.ft to 10000sqft.

- it is possible...but with the current ever rising cost of steel...it is more expensive than reinforced concrete..... ...one more disadvantage is tat u have to use large I sections for the columns as steel do not take compression as good as concrete... ..tat is why u see..almost all totally steel structures are bridges where tensile strength rules more than compression.

- Q: How are steel coils coated for added protection?

- Steel coils are coated for added protection using a process called coil coating. This process involves the application of a protective layer onto the surface of the steel coil to enhance its durability and resistance to corrosion. There are various methods used to coat steel coils, but the most common one is the continuous coil coating process. In this process, the steel coil is unwound and cleaned thoroughly to remove any contaminants or impurities from the surface. This ensures proper adhesion of the coating material. Once the steel coil is cleaned, it is then pre-treated to enhance its surface properties. This pre-treatment typically involves applying a chemical solution or a conversion coating to the surface of the coil. The purpose of this step is to create a receptive surface for the coating material and enhance its adhesion. After the pre-treatment, the steel coil is coated with a protective layer. This coating material can be a liquid paint, a powder coating, or sometimes a combination of both. The coating is applied uniformly onto the surface of the coil using various techniques, such as roll coating, spray coating, or electrostatic coating. Once the coating is applied, the steel coil is cured or dried using heat or sometimes ultraviolet light. This curing process ensures that the coating material forms a strong bond with the steel surface and achieves the desired protective properties. The coated steel coil is then inspected for quality control measures, such as thickness, adhesion, and appearance. If it meets the required specifications, it is further processed, which may involve cutting, slitting, or forming into the desired shape or size. Overall, the process of coating steel coils for added protection involves thorough cleaning, pre-treatment, application of a protective coating, curing, and quality control. This ensures that the steel coils possess excellent resistance to corrosion, abrasion, and other environmental factors, making them suitable for a wide range of applications in various industries.

- Q: How are steel coils unloaded from a truck?

- Typically, specific equipment and a well-coordinated process are utilized to unload steel coils from a truck. To ensure the safe and efficient removal of the coils, the unloading process consists of multiple steps. First, a forklift or crane is commonly employed to reach into the truck bed and secure the steel coil. The operator of the forklift or crane carefully positions the lifting apparatus underneath the coil, ensuring that it is centered and balanced. Once the steel coil is securely fastened, the forklift or crane gradually raises it out of the truck bed while maintaining stability. The operator must exercise caution and consider factors such as the weight and dimensions of the coil to prevent any accidents or damage. After the steel coil is lifted out of the truck, it is typically placed onto a designated area, such as a flatbed trailer, storage rack, or directly onto the ground. If placed on the ground, wooden blocks or rubber mats are often utilized as protective measures to prevent any damage to the coil or the surface it is placed on. In certain instances, a specialized coil trailer equipped with hydraulic systems may be used to unload the steel coils. This method is particularly beneficial for unloading larger and heavier coils, as it allows for the tilting of the trailer bed and rolling off the coil. In conclusion, unloading steel coils from a truck necessitates skilled operators, appropriate lifting equipment, and adherence to safety protocols. It is crucial to meticulously follow these steps to ensure the safe and efficient unloading of steel coils.

- Q: What are the common applications of steel coils in construction?

- Steel coils are commonly used in construction for various applications such as structural components, including beams, columns, and trusses. They are also used for roofing and cladding systems, as well as in the fabrication of reinforcing bars and precast concrete elements. Additionally, steel coils are utilized in the manufacturing of pipes, tubes, and sheet metal products, serving as a crucial material in the construction industry.

- Q: I would like to buy a new cold steel recon 1 folding knife. My concern is the knife is made in Taiwan, will the quality of blade/overall make is lower quality compare with those made in US/JAPAN? The plan is use as an EDC, any good suggestion with similar style? Most important to me is reliability, 2)sharpness, 3) maintance than 4)cost. Anyone can point me into right direction? Please share, Thanks in advance.

- Cold okorder /

- Q: What are the different methods of storing steel coils?

- There are several different methods of storing steel coils, including vertical stacking, horizontal stacking, eye-to-the-sky stacking, and interlocking stacking. Each method has its own advantages and considerations based on factors such as space availability, weight distribution, and accessibility for transportation and handling. Ultimately, the choice of storage method depends on the specific requirements and constraints of the steel coil storage facility.

- Q: What are the common methods of handling steel coils during production?

- There are several common methods for handling steel coils during production. These methods are designed to ensure the safe movement and storage of the coils, as well as to facilitate efficient processing. 1. Forklifts: Forklifts are commonly used to move steel coils within a production facility. They are equipped with specialized attachments, such as coil rams or coil hooks, that securely grip the coil and allow for easy transport. Forklifts are ideal for moving coils over short distances or between different areas of the production floor. 2. Overhead cranes: Overhead cranes are another popular method for handling steel coils. These cranes are typically mounted on rails and can span the entire length of a production facility. They use lifting devices, such as C-hooks or magnets, to securely lift and transport the coils. Overhead cranes are particularly useful for moving large or heavy coils over longer distances. 3. Coil cars: Coil cars are specialized rail-mounted vehicles that are designed to transport steel coils within a production facility or between different areas of a steel mill. These cars feature adjustable arms or forks that can be positioned to securely hold the coils. Coil cars are often used when large quantities of coils need to be moved at once. 4. Coil racks: Coil racks are used for storing steel coils in a vertical position. These racks are typically made of heavy-duty steel and are designed to hold multiple coils securely. They are commonly used in warehouses or storage yards to maximize space and facilitate easy access to the coils. 5. Coil trailers: Coil trailers are specially designed trailers that are used for transporting steel coils over long distances. These trailers have built-in coil cradles or bunks that securely hold the coils during transit. They often feature adjustable or removable coil racks to accommodate different sizes or configurations of coils. Overall, the common methods of handling steel coils during production involve the use of specialized equipment such as forklifts, overhead cranes, coil cars, coil racks, and coil trailers. These methods prioritize the safety of the workers and the integrity of the coils, while also ensuring efficient movement and storage throughout the production process.

- Q: Is there a difference between hot rolled and cold rolled steel coils?

- Yes, there is a significant difference between hot rolled and cold rolled steel coils. Hot rolled steel coils are produced at high temperatures and are typically used for applications that require malleability and ductility. On the other hand, cold rolled steel coils are produced at room temperature and undergo a process that results in a smoother, more precise finish. Cold rolled steel coils are often used in applications that require a higher degree of strength and surface quality.

Send your message to us

High Quality 201 Stainless Steel Coil for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords