High-Pressure Laminates Used Kitchen HPL

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of HPL:

HPL are high quality decoration material , which are widely applied to furniture,kitchen cabinet,cupboard, countertop, window, door skin, wall lining, partition, ship lining ,ceiling, lift lining, shop fitting,shelving, etc .

Fireproof board / refractory plate is base paper after melamine resin and phenolic resin processing, main physical properties is unfolded by the characteristics of the resins. After the melamine resin thermosetting moulding have luster good, good transparency, high surface hardness, wear-resisting, withstand high temperatures, impact resistance, surface pores small is not easy to be contaminated, chemical resistance, water resistance, resistance to solvent, flame resistance and other excellent performance, mechanical strength, electrical insulation, resistance to arc good and is not easy to aging. Phenolic resin thermoset molding after heat and hard performance. Two kinds of resin combination, fireproof board / refractory plate contains both the performance.

2.Feature of HPL:

1) Finishied via impregnating the decorative paper and kraft paper in melamine,drying and high temperature and presure

2) Outstanding resistance to abrasion,high tempreature,dirty,shocking,cigarette ignition and open flame

3) Exceptional mould proof performance ,has very wide application and very big market potential

4) Decorative surface material for both indoor and outdoor use

5) Widely used in surface decoration of rooms, offices, compartments, partitions, kitchens, sideboards, furniture and laboratory table tops

6) wear-resistant, fire-resistant, anti-static, chemical resistant

7) Acid resistance and alkali resistance

8) Abrasive resistance

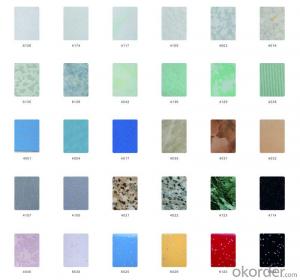

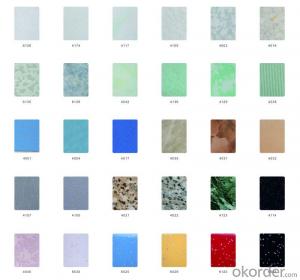

3. Images of HPL:

4.Specifications of HPL:

1. size

1220mmx2440mm 1220mmx3050mm 1310mmx2440mm 1310mm x3050mm

2. thickness

Standard HPL: 0.5mm~1.0mm.

Post-forming HPL: 0.5mm~0.6mm.

Metallic HPL: 0.7mm~1.0mm

Compact: 1.0mm~12mm.

3. color

Solid/plain color, fantastic color, wood grain color, metal, wooden veneer or customized color

4. surface finishing Glossy, Matt, Texture and some other special surfaces.

5. packing Wooden case for HPL/ wooden Pallet for Compact Laminate

0.5mm: LOAD: 14 cases per 20ft container, 600pcsX14cases=8400PCS

WEIGHT: 2.2KGX8400PCS+80kgX14cases=19.60TON

0.6mm: LOAD: 14 cases per 20ft container, 500pcsX14cases=7000 PCS

WEIGHT: 2.7KGX7000PCS+80kgX14cases=20.02TON

0.7mm: LOAD: 14 cases per 20ft container, 450pcsX14cases=6300 PCS

WEIGHT: 3.1KGX6300PCS+80kgX14cases=20.65TON

0.8mm: LOAD: 14cases per 20ft container, 400pcsX14cases =5600 PCS

WEIGHT: 3.6KGX5600PCS+80kgX14cases=21.28TON

5.FAQ

1. What kind of certificate do you have?

ISO9001, CE, UL,CARB, CNAS

2. What color can you produce?

Solid color wood grain color or according to customs' requirements.

3. How about the samples?

For the samples, it will be prepared ASAP.

4. Do you charge for the Samples?

According to our company policy, we will charge you the express fee in the first time but the sample will be free. While we start our business, we will reimburse the money for you

5. Can you produce according to customer's design?

Sure, we are professional manufacturer, OEM are welcome. While the beginning you need to pay the moulded open fees and Orders meet the minimum ordering quantity of special products

- Q: Pipeline insulation materials, which are generally several types of fire protection

- Building materials fire rating of the following four grades: A: non-flammable Building materials: almost no combustion. B1 level: flame retardant building materials: a good flame retardant effect, in the air case of fire or high temperature is not easy to fire, not easy to spread, and in the open fire will immediately stop burning. B2 grade: flammable building materials: a certain role in the fire, in the air in case of fire or high temperature will immediately fire burning, easy to lead to fire spread, such as wood structure housing. B3: Flammable Building materials: no flame retardant effect, easy to burn, fire a great danger.

- Q: The fire resistance of building materials includes the nature of building materials

- Flame retardant, oxygen index of 20 or more.

- Q: What is the thickness of the thick fireproof coating?

- Generally do not ask what the thickness of the bar, painted three times on the OK you

- Q: Decorative materials Fireproof paint three degrees What does it mean

- Fireproof paint does not have this word "three degrees"

- Q: A simple chemical problem!

- B is correct from the activated carbon to absorb the gas, the early use of the filter gas masks. C silica gel is not anti-oxidation, is moisture absorption

- Q: Indoor to do with the gypsum board or good or good use of fire board board, fire board is made of what material ah how environmental

- Do wall, then, gypsum board preferred. Cheap, sex Geng Ji Li Li Dian Dian for the bite force can be good. Do not use wood, moisture easily deformed! Fire board is now called the law is not uniform, there are metal panels inside the folder perlite. There is also a layer of wood on the surface of a fireproof material. As well as take carpentry in the fire liquid soak! The Do not know how the decoration company told you! The

- Q: What are the building firefighting materials?

- Fire extinguisher, fire alarm, fire alarm, fire alarm, fire alarm, fire alarm, fire alarm, fire alarm, fire alarm, fire alarm, fire alarm, fire alarm , Fire, fire, fire, fire, fire, fire, fire, fire, fire, fire, fire, fire, fire, fire, fire, fire, A sense of manual alarm button, sound and light alarm, and so on

- Q: What are the standards for national fire-resistant materials?

- Fireproof material grade: Class A: incombustible building materials, almost no burning material. A1 level: non-combustible, can not afford to fire A2 level: non-combustible, to measure smoke, to qualified. B1 level: flame retardant building materials: flame retardant materials have a better flame retardant effect. It is in the air in case of fire or in the role of high temperature difficult to fire, it is not easy to spread, and when the fire destroyed after the fire immediately stop. B2 grade: flammable building materials: combustible materials have a certain role in flame retardant. In the air in case of fire or under high temperature will immediately fire burning, easy to lead to the spread of fire, such as wooden pillars, wooden truss, wooden beams, wooden stairs and so on. B3 level: flammable building materials, without any flame retardant effect, easy to burn, fire a great danger.

- Q: What is the bulk density of rock wool A grade fireproof material?

- General 120KG / cubic meter

- Q: Polystyrene board is A-class or B-class fire insulation materials

- According to the national standard in 2002: GT / T / 0801.1-2002 (expanded polystyrene board) and GT / T / 0801.2-2002 (extruded polystyrene board), these two polystyrene board should reach B2 level.

Send your message to us

High-Pressure Laminates Used Kitchen HPL

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords