High Alumina Bricks High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Shandong, China (Mainland) | Shape: | Brick | Material: | calcined flint clay,mullite,bauxite |

| Refractoriness (Degree): | 1770°< Refractoriness< 2000° | Brand Name: | ZYC |

Packaging & Delivery

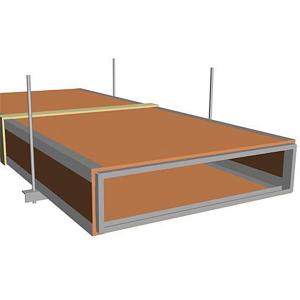

| Packaging Details: | On wooden pallets with plastic films cover |

| Delivery Detail: | Within 20days after the order |

High alumina steel ladle fire brick,Steel ladle brick,Ladle brick

Features:

1) High-temperature endurable .

2) Good thermal shock resistance .

3) Good resistance to abrasion and corrosion.

4) Good thermal shock and thermal spalling resistance.

5) High mechanical strength.

6) Good volume stability at high temperature.

Physical and chemical index:

ITEM | INDEX | |||

CL-80 | CL-75 | CL-65 | CL-55 | |

AL2O3 (%) (≥) | 80 | 75 | 65 | 55 |

Refractoriness °C(≥) | 1790 | 1790 | 1790 | 1770 |

Apparent porosity % (≤) | 24 | 28 | 28 | 22 |

Cold crushing strength MPa (≥) | 50 | 40 | 35 | 35 |

Refractoriness Under Load 0.2 MPa °C (≥) | 1530 | 1510 | 1490 | 1470 |

Linear change after reheating (%) | 1530C×2h +0 ~ -0.4 | 1500C×2h +0.1~ -0.5 | 1500C×2h +0.1~ -0.5 | 1450C×2h +0.1~ -0.4 |

- Q: Color steel plate sandwich to use fireproof material, what is good?

- Rock wool board insulation, sound insulation effect is good

- Q: Are you using fireproof materials for decoration?

- Sure to ah, such as the switch panel burned, there must be a layer of Shuo plastic bedding, not easy to cause flammable, but also early hair problems

- Q: Do you need to do floor fire isolation? There are those regulations for fire protection

- 2.10 The cable wells and pipe wells in the building shall be burned at every floor of the building. The non - combustible body shall not be used at a level not exceeding the fire resistance of the floor. Or fire blocking material plugging.

- Q: The fire resistance of building materials includes the nature of building materials

- Flame retardant, oxygen index of 20 or more.

- Q: Extruded board fire B1, B2 grade material how to distinguish

- Fire level and density does not matter, with the lighter point can not fully explain the problem, b1 level to compound gb8624b1 level

- Q: Short point is to do hand copy

- Several common fire fighting methods: 1, furniture, bedding and other fire: the general use of water fire. With water around the items such as the basin and so on to the flame on the water, but also the water pipe connected to the faucet sprinkler fire; at the same time the burning point near the combustible humidification. But the oil, electrical fire can not use water to fire. 2, electrical fire: household appliances or lines on fire, we must first cut off the power, and then dry powder or gas fire extinguisher, can not directly splash water to prevent electric shock or electrical explosion wounding. 3, the TV fire: TV in case of fire, never water, you can cut off the power, with a quilt to cover it. Fire, only from the side close to the TV, to prevent the camera tube explosion wounding. If the use of fire extinguishers fire, should not be directed to the TV screen, so as to avoid the sudden cold after the heat and explosion. 4, the pan fire: the oil pan should quickly shut down the stove gas valve, directly cover the lid or cover with a wet cloth, but also to the pot put the chopped vegetables to cool the fire, the pot smooth from the fire, After cooling to open the lid, do not pour water to the oil pan. 5, gas tank fire: use wet bedding, clothing and other cover fire, and quickly close the valve. 6, the body of the fire, do not run around, can be used to roll or heavy clothing to suppress the flames. Wearing a wet towel, handkerchief and so cover your nose and mouth, try to make the body close to the ground, bending or creeping forward.

- Q: Fire doors with fire insulation materials which?

- Fire doors with fire insulation materials fire doors made of steel materials, door frames, door frames and door panels, doors if filled material, then fill the human body non-toxic harmless fire insulation materials, and with fire hardware accessories With a certain fire resistance of the door. Fire doors general technical conditions of the standard This standard specifies the wood fire door product classification, size specifications, technical requirements, test methods, inspection rules, logo packaging, transportation and storage. This standard applies to the use of wood or wood products for the door frame, door frame, door panel fire door. Emergency and statistical functions, the system can automatically display on the computer specified cardholder's physical location, easy to contact in time. Fire and other emergencies, the electronic fire door will automatically open, easy to escape, the entrance can also be automatically opened; when the illegal out of time, will automatically alarm.

- Q: What does the fire door frame fill with?

- The top of the floor if the gap between the door frame and the wall is not the general seal glue on the OK to open the gap, then it is the construction of the marshchel rap snaer に inn

- Q: Members colleagues, brother just into the Bank, it is necessary to use the Mylar film, what Mira is the material. Thank you more

- 1 Ingredients Mylar Sheet (MYLAR Sheet) PET polyester film is a film made by the reaction of dimethyl terephthalate and ethylene glycol under the aid of a related catalyst, followed by transesterification and vacuum polycondensation, biaxially stretching The 2 classification Mylar film appearance of milky white, black, natural, transparent color and other color classification. Mylar tablets have a variety of materials, such as PET Mylar, PVC Mylar, PC Mylar, Fire Mile and so on. Applications are divided into: insulation, cushioning, wear-resistant, sealed and the appearance of decorative type Mylar. 3 features a stable, straight and excellent anti-tear strength, heat and cold, moisture and water resistance, chemical resistance, and has superior insulation properties, excellent electrical, mechanical, heat resistance, chemical resistance. 4 use can be used for motors, capacitors, coils, cables, insulation materials, but also with the barley paper made of composite insulation materials. It is widely used in electrical insulation industry, suitable for electronics, household appliances, instruments, monitors, motor slots, computers and peripheral equipment 粻 hungry thirsty leek blood clot gasket, file, screen and protection. Attachment: can replace the general tape, suitable for electronic components in the machine when packaged for packaging, so that electronic components can be used in the more secure. Hope to help you! If you need to purchase Mylar tablets can contact our company absolutely cheap price for quality goods! Hope to create a win-win with your company!

- Q: What kind of good insulation materials for cold storage?

- Polyurethane spray ah urethane large board rock wool board glass wool board

Send your message to us

High Alumina Bricks High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches