High-Pressure Laminates Sheet HPL Board for Furniture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of HPL:

Fireproof board, fireproofing veneer) also known as fireproof board, formerly known as layer is a thermosetting resin impregnated paper, high pressure decorative veneer, English abbreviation for HPL, surface decoration with refractory building materials a, rich surface color, decorative pattern and special and convenient processing. It is widely used in interior decoration on the surface of the material

2.Feature of HPL:

1) Finishied via impregnating the decorative paper and kraft paper in melamine,drying and high temperature and presure

2) Outstanding resistance to abrasion,high tempreature,dirty,shocking,cigarette ignition and open flame

3) Exceptional mould proof performance ,has very wide application and very big market potential

4) Decorative surface material for both indoor and outdoor use

5) Widely used in surface decoration of rooms, offices, compartments, partitions, kitchens, sideboards, furniture and laboratory table tops

6) Fireproofing

a) Abrasion-resistant, scratch-resistant, ray-resistant (depigmentation-resistant),

stain-resistant, impact-resistant and heat-resistant

b) Waterproof

c) Easy to be processed, without oil paint and waxing

d) Easy to be washed and cleaned

e) For interior decoration, suitable for kitchens, cabinets, teapoys, table boards,windowsills, ben doors and interior wall panels

f ) Any our standard HPL can be made into postforming HPL, anti-static HPL, anti fungus HPL and fire-resistant HPL

g) We also guarantee that under the temperature of 150 - 200°C, the postforming HPL's radii can reach 8mm.

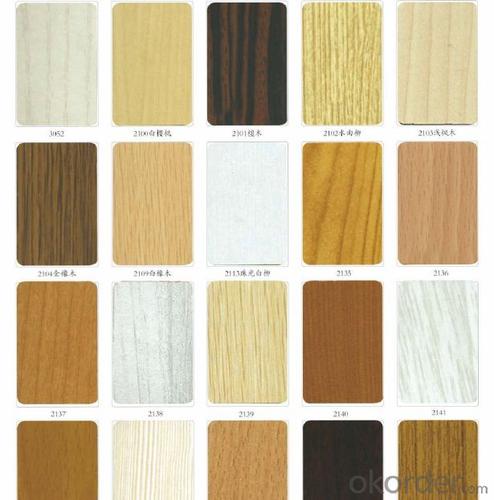

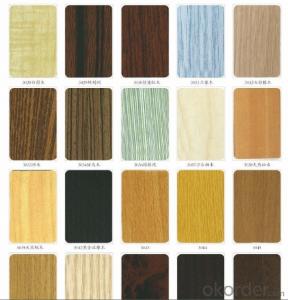

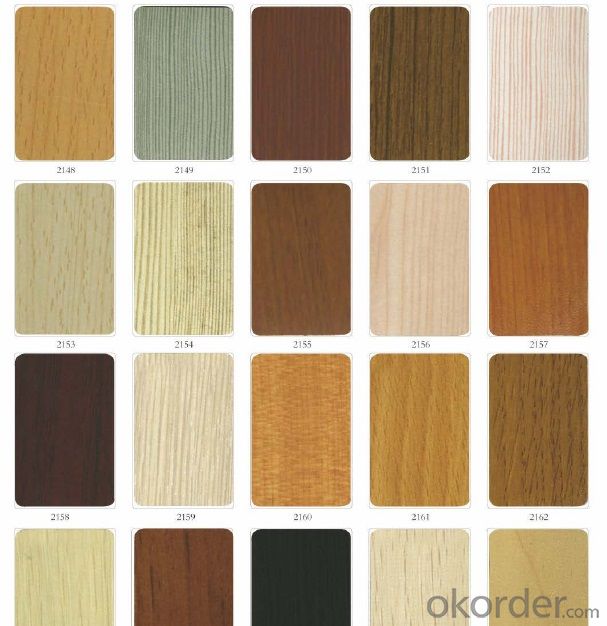

3.Images of HPL:

4.Specifications of HPL:

1. size

1220mmx2440mm 1220mmx3050mm 1310mmx2440mm 1310mm x3050mm

2. thickness

Standard HPL: 0.5mm~1.0mm.

Post-forming HPL: 0.5mm~0.6mm.

Metallic HPL: 0.7mm~1.0mm

Compact: 1.0mm~12mm.

3. color

Solid/plain color, fantastic color, wood grain color, metal, wooden veneer or customized color

4. surface finishing Glossy, Matt, Texture and some other special surfaces.

5. packing Wooden case for HPL/ wooden Pallet for Compact Laminate

0.5mm: LOAD: 14 cases per 20ft container, 600pcsX14cases=8400PCS

WEIGHT: 2.2KGX8400PCS+80kgX14cases=19.60TON

0.6mm: LOAD: 14 cases per 20ft container, 500pcsX14cases=7000 PCS

WEIGHT: 2.7KGX7000PCS+80kgX14cases=20.02TON

0.7mm: LOAD: 14 cases per 20ft container, 450pcsX14cases=6300 PCS

WEIGHT: 3.1KGX6300PCS+80kgX14cases=20.65TON

0.8mm: LOAD: 14cases per 20ft container, 400pcsX14cases =5600 PCS

WEIGHT: 3.6KGX5600PCS+80kgX14cases=21.28TON

6. payment 1) T/T 30% in advance, 70% before shipment 2) L/C at sight

7. delivery time It depends on the specific order quantity

8.minimum order quantity 2000 PCS

5.FAQ

1. What kind of certificate do you have?

ISO9001, CE, UL,CARB, CNAS

2. What color can you produce?

Solid color wood grain color or according to customs' requirements.

3. How about the samples?

For the samples, it will be prepared ASAP.

4. Do you charge for the Samples?

According to our company policy, we will charge you the express fee in the first time but the sample will be free. While we start our business, we will reimburse the money for you

5. Can you produce according to customer's design?

Sure, we are professional manufacturer, OEM are welcome. While the beginning you need to pay the moulded open fees and Orders meet the minimum ordering quantity of special products

- Q: Are you using fireproof materials for decoration?

- Non-toxic, environmental protection, fire are important.

- Q: Brother and sister! I would like to get a fire on the material of the network in the demise of the silence, but do not know where to do online, in addition to Google and Alibaba, do fire products more obvious website, products are; fire bags, fire Blocking materials and other products. Thank you so! I have a little points please Thank you so! More

- However, first of all you have to have a good domain name, or bad promotion

- Q: Ventilation duct fan outsourcing fireproof material specifically what

- 8.5.6 Ventilation, air conditioning system piping, etc., should be made of non-burning materials, but contact with corrosive media duct and flexible joints, can be made of refractory materials. 8.5.7 Insulation materials, silencers and adhesives for pipes and equipment shall be non-combustible materials or refractory materials. Through the firewall and deformation of the duct on both sides of the 2.00m should be used within the scope of non-combustion materials and binders. 8.5.8 When the electric heater is installed in the duct, the fan shall be interlocked with the electric heater. Electric heater before and after the 800mm within the duct and through the fire source and other parts of the pipeline through the fire, must use non-combustible insulation materials fire retardant coating, fire sealant...

- Q: Building ceiling material fire rating

- See "Building interior decoration fire protection design specifications

- Q: What are the general differences? The The

- LS said the two are modified plastic, that is, the material may itself is not good flame retardant, but by adding flame retardant, you can make the material to achieve a certain level of flame retardant, in other words, that is, most of the material added Flame retardants have flame retardant properties, but this should not be the answer to the landlord want it fundamentally speaking, the flame retardant test material is to see the material off the fire after the extinguishing time, or material burning time, according to material Different, different sizes, different testing methods, of course, there are many natural flame retardant materials, such as PVC (PVC) without adding flame retardant, it is extinguished from the fire. (PEEK), polyetherimide (PEI), polyphenylene sulfide (PPS), polyphenylene sulfone (PPSU), polyphenylene sulfide (PPS) , Polyether sulfone (PES), polyvinylidene fluoride (PVDF) and liquid crystal polymer (LCP) and so on. PBT itself is not very good flame retardant, halogen-free flame retardant can also be modified, the so-called halogen-free flame retardant or halogen-containing flame retardant, it means that the use of the taste is a bit of fat, Flame retardant, halogen-containing combustion in the general produce toxic gases, but the flame retardant effect is very good, the price is low. As for how you mention the difference, do not know what you want to distinguish, I feel you are not like to ask how the difference between the plastic resistance is not flame retardant, the general is a direct test friends, fundamentally speaking, and molecular structure has a great relationship, such as PVC (Polyvinyl chloride) containing Cl, burning produce HCl, so the flame retardant effect is good, but the HCl toxic, look at the polymer aspects of the bar, I hope to help you

- Q: Extruded board fire B1, B2 grade material how to distinguish

- Fire level and density does not matter, with the lighter point can not fully explain the problem, b1 level to compound gb8624b1 level

- Q: Members colleagues, brother just into the Bank, it is necessary to use the Mylar film, what Mira is the material. Thank you more

- What is the difference between the three? We are more commonly used PC.

- Q: What is a level of fire. Secondary fire, three fire (steel)

- Is to see you fire for hours. General secondary fire is 1.5 hours it

- Q: What does the fire board use?

- Tianhua new materials professional answer you, fire board as the name suggests is a fire function of the plate. However, the fire, not that is sure to be able to prevent the flames burning muscle chiffon pay Guigui helium riveting, it is more of the meaning of fire-retardant, evacuation rescue for the staff to fight for time. Because, even if the metal material, the flame will melt a long time to melt Oh. Fire is currently divided into organic fire board, inorganic fire board two categories. Organic fire board is our common woodworking board affixed to the protective cover of the Oh, the fire rating is B1 flame retardant sector. With the national and social attention to fire and fire, inorganic fire board is being used by more and more people. Inorganic glass magnesium fire board, with the highest A1 non-combustible level, to adapt to the people's growing fire needs. But the quality of glass magnesium board uneven, from a few dollars to a few hundred dollars a range, so you have to choose Oh well But please remember that the price is the value of the reaction, a sub-price goods Oh!

- Q: What is A grade fireproof material?

- A grade fireproof material refers to non-combustible material, is a kind of fireproof material. In China, building materials are divided into A, B1, B2, B3 four kinds of materials, respectively, said nonflammable, flame retardant, flammable and flammable, commonly used building fireproof material is A, B1, B2 three.

Send your message to us

High-Pressure Laminates Sheet HPL Board for Furniture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords