Recyclable Fireproof Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

100% Recycling Soundproofing Closed Cell Aluminum Foam Panel

What is AluminumFoam?

Aluminum foam is a new concept metalmaterial which is foamed in sponge shape after melting aluminum ingot with various chemical ingredients and has many bubble layers inner structure.

Porous material is much lighterthan original one, which is the characteristic of porous. And, it improves the ability of energy absorption and reduces the abilityof thermal and electrical conductivities than original metal materials. Inaddition, porous material has wide applications as well as excellent ability ofsound absorption and permeability of liquid, air, etc.

Aluminumfoam, a metal itself, can be applied to aerospace aviation required the thermostability over 200℃. It is a 100% recyclabl ecofriendly material and absolutely will not produceharmful substances no matter in the process of producing, using or abandoning.

Main properties of aluminum foam

Density is 0.2~0.4g/cm3 (Aluminium1/10,Iron1/30, and Wood 1/4)

Soundabsorption

Porous structure has a good soundabsorption.

Aluminum foam sound-absorbing materialcan be used in the inner decoration of buildings (walls, ceiling and floor),railway, highway, factories, mechanical equipment and any other fields.

Suitable for noisy place.

100%non-flammability and no toxic gas released when burning.

Non-combustibility TEST verified to be qualified. <KIMM; IMO A.799 (19)>

I grade Non-flammability TEST ofaluminum foam surface verified to be qualified. <KICT; KS F2271>

Energyabsorption

Porous structure can effectively absorbenergy.

Have a great effect on energyabsorption after a high impact.

Firstly acquired the national SB5class (Guard rail shock-absorber)

Electromagnetic wave shielding ability

Aluminum foam has a function ofabsorbing electromagnetic wave

Widely used in military (stealth materials),TV station, hospital and any other electromagnetic shielding places.

100% recyclable Aluminum foam is nonpoisonous, odorless andharmless, no toxic gas released when burning.

Aluminum foam can be produced by recycled aluminum andits scraps.

ProductFeatures

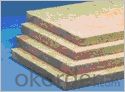

Item | Aluminum foam composed panel | Aluminum honeycomb plate |

Material | Aluminum | Aluminum |

Structure | Aluminum plate(GRP plate) aluminum foam aluminum plate(GRP plate) | Aluminum plate(GRP plate) aluminum honeycomb aluminum plate(GRP plate) |

(long time immersion and corrosion in water) | Excellent(oxidized pure metal) | Excellent but easy to rust |

Excellent (Non-flammability of pure metal) | General (Glue layer in the middle is not resistant to high temperature) |

ComparisonAluminum Foam with Other Sound-absorbing Materials

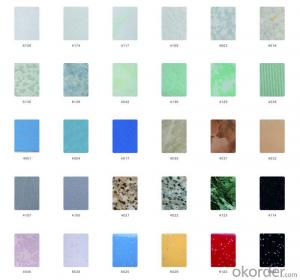

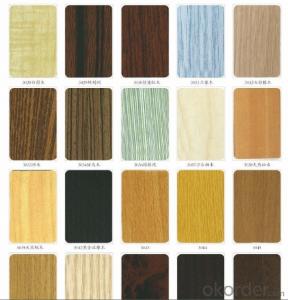

Type | Aluminum Foam | Polyester | Glass Fiber | Urethane Form |

Shape |

|

|

|

|

Material | Aluminum | Polyester | SiO2, mineral | high molecular Material |

Acoustic absorption(NRC Standar d) | over 0.70 | over 0.70 | over 0.75 | over 0.65 |

Long-term sound absorption | Permanent | Property is decreased | Property is decreased | Property is decreased |

Eco-friendly | 100% recyclable Eco-friendly | No recyclable, flammable, produce little dust | No recyclable, no flammable, arsenic acid cause gas pollution | No recyclable and flammable |

Materials handling & Constructability | Easy handling, using and working under no protective equipment | No damage when handling and using, easy to work under no protective equipment | Low stability. Easy to cause respiratory disease and skin ailments when touching | No damage when handling and using, easy to work under no protective equipment |

Human harmfulness | Harmlessness | Harmlessness | Harmfulness | Poisonous gas (CO, Cyan gas) release when burning |

Waterproofness & Sound absorption | Waterproofness is excellent , stable form, permanent sound absorption | Waterproofness and adhesion is good, stable form | Absorb moisture and poor drainage cause lower acoustic absorption | Absorb moisture and poor drainage cause lower acoustic absorption |

Non-flammability | Ⅰgrade Non-flammability | Heat-resistant | Easy flammable |

- Q: Is it permissible or permitted to block the use of fireproofing in cable ducts?

- Cable wire bridge through the fire zone specification must be used to block the fireproof material!

- Q: What are the general differences? The The

- LS said the two are modified plastic, that is, the material may itself is not good flame retardant, but by adding flame retardant, you can make the material to achieve a certain level of flame retardant, in other words, that is, most of the material added Flame retardants have flame retardant properties, but this should not be the answer to the landlord want it fundamentally speaking, the flame retardant test material is to see the material off the fire after the extinguishing time, or material burning time, according to material Different, different sizes, different testing methods, of course, there are many natural flame retardant materials, such as PVC (PVC) without adding flame retardant, it is extinguished from the fire. (PEEK), polyetherimide (PEI), polyphenylene sulfide (PPS), polyphenylene sulfone (PPSU), polyphenylene sulfide (PPS) , Polyether sulfone (PES), polyvinylidene fluoride (PVDF) and liquid crystal polymer (LCP) and so on. PBT itself is not very good flame retardant, halogen-free flame retardant can also be modified, the so-called halogen-free flame retardant or halogen-containing flame retardant, it means that the use of the taste is a bit of fat, Flame retardant, halogen-containing combustion in the general produce toxic gases, but the flame retardant effect is very good, the price is low. As for how you mention the difference, do not know what you want to distinguish, I feel you are not like to ask how the difference between the plastic resistance is not flame retardant, the general is a direct test friends, fundamentally speaking, and molecular structure has a great relationship, such as PVC (Polyvinyl chloride) containing Cl, burning produce HCl, so the flame retardant effect is good, but the HCl toxic, look at the polymer aspects of the bar, I hope to help you

- Q: Today, see the Christine plant more broken off the German vouchers fan of the CCTV news channel reported that the district energy-saving transformation, the workers are more tense, the first use is to meet the A-class thermal insulation materials, later said to be polyurethane insulation board, and then use the fire A little moment on the smoke, and quickly took the fire machine, then smoke did not burn out, repeated several times did not dare how, this insulation board really fire? More

- China's national standard GB8624-97 will burn the performance of building materials are divided into the following grades A: non-flammable Building materials: almost no combustion of the material. B1 level: flame retardant building materials: flame retardant materials have a better flame retardant effect. In the air, there is no fire in the case of high temperature, it is not easy to spread quickly, and when the fire is removed, the burning stops immediately. B2 grade: flammable building materials: combustible materials have a certain role in flame retardant. In the air in case of fire or under high temperature will immediately fire burning, easy to lead to the spread of fire, such as wooden pillars, wooden truss, wooden beams, wooden stairs and so on. B3 level: flammable Building materials: no any flame retardant effect, easy to burn, fire risk is great. Polyurethane insulation board after flame retardant treatment up to B1 level.

- Q: Phenolic insulation board is B1 grade fireproof material

- A2 We specialize in the production of phenolic insulation board modified phenolic insulation board

- Q: What are the building firefighting materials?

- Fire water, fire pumps, fire pumps, wet alarm valves, water pump adapters, shower heads, indoor (outdoor) fire hydrants, flow indicators, signal valves, galvanized pipes and fittings, etc .; fire main fire alarm series , Emergency evacuation series, radio and other communications; gas fire mainly include cylinders, pharmaceuticals, manifolds, selection valves, high pressure pipe fittings, nozzles, etc .; in addition to smoke control system, fire doors, fire shutter, fire window Wait

- Q: What kind of good insulation materials for cold storage?

- Large-scale cold storage generally use polyurethane insulation board B2-level flame retardant more B1, then the price is too high general business can not afford

- Q: What is the bulk density of rock wool A grade fireproof material?

- 60-220kg general use of different local requirements so different capacity

- Q: Ul94v-0 refers to the fire level or a material

- UL94V-0 is UL94 standard V-0 flame retardant grade. Specified UL94 standard.

- Q: Class C fire door with what material

- Material is the same, in the thickness or strength of the difference

- Q: Basement ceiling extrusion board insulation material fire rating What are the requirements? What are the requirements of fire acceptance?

- This is now a lot of provinces are required to urge the A1 level, the key to see your local fire situation. What is your province? Also need to know whether the building is a civil building or commercial, each other at the height of the height?

Send your message to us

Recyclable Fireproof Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords