Calcium Silicate Boards Model 02 for Exporting

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1Container pc

- Supply Capability:

- 35000Pcs/Day pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

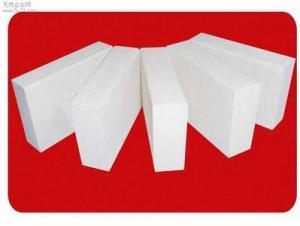

Description of Calcium Silicate Board:

A calcium silicate board is one of the new-type building materials recommended by the Ministry of Construction. It is a light, high-strength, fire-resistant and heat-proof material composed of scientific proportions of siliceous and calcareous materials, adulterated with appropriate amount of reinforcing materials, which are processed through pulping, molding, autoclave curing, drying and sandpaper polishing.

Main component:

Wood fiber, cement and so on. The nominal size is 1220*2440/1200*2400, with the maxium length 3.66m.

Technical Datas of Calcium Silicate Board:

1.100% non-asbestos

2. Density: 1000-1200 KG/m3

3. Coefficient of thermal expansion: 0.24W/MK(JC/T54)

4. Bending strength: Over 13Mpa(GB/T7019-1997)

5. Linear expansion rate: 0.1%

6. Water absorption rate: Less 0.19%(GB/T7019-1997)

7. Water penetration rate: 0%

8. Water content: 10%

9. Incombustibility: 180 minutes

10. Incombustibility, A grade; Waterproof

11. Radioactivity: Standard(GB6566-2000)

Main Characteristics of Calcium Silicate Board:

1. Light weight

2. The wall is solid and firm inside, and resistant to impact pressure

3. Painting, tiling and nailing is possible in the new system

4. Noise reduction can be up to 46 dB

5. Good efficiency

6. Fireproof, damp proof

7. Easy to install 8. Stable dimensions

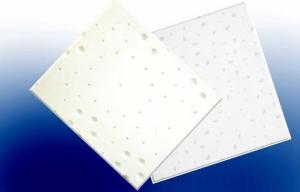

Specifications of Calcium Silicate Board:

1) Thickness: 4 - 20mm

2) Normal Size: 1220*2440/1200*2400, with the maxium length 3.66m.

Usage of Calcium Silicate Board:

The magnesium board is widely adoptable to partition and suspending ceiling in decoration of buildings. It is also absolutely suitable to the structure for heat preservation, sound insulation wall places with dampness, mobile partition, special class fire prevevention, sandwiched plate in fireproof- gate and packaging of equipment cases.

Packaging & Delivery of Calcium Silicate Board:

Pieces with palletes or pieces loosely in the container.

- Q: Calcium silicate board ceiling need to do the bottom plate

- Should not be used. Calcium silicate board ceiling is based on silicon oxide (quartz sand, powder, silicon, algae, etc.), calcium oxide (also protect the child pole twisted pony ghost Creek Gong Lou useful lime, carbide slag, etc.) and reinforcing fiber Calcium board is a new generation of "green" building materials, in the excellent moisture, fire performance based on the unique environmental protection function.It is based on silicon powder and calcium powder as the main substrate to hot wood fiber as a reinforcing material, Auxiliary materials, through the flow slurry molding, in the high temperature, high pressure maintenance of a new type of fire board building materials.

- Q: Calcium silicate board does not hang plaster can directly stick tiles? Calcium silicate board is not often said that the cement pressure office for the edge of a good spring equipment, Are they different? Also, what are the specifications of the calcium silicate board? Calcium silicate board has a wall cut between the processing, what are the shortcomings? Thank you more

- Calcium silicate board is lime and stone powder and into, because waterproof, so can not directly stick tiles. (Long time will fall off) calcium silicate board and cement board is two kinds of boards, cement board is made of mixed materials, (house demolition of waste) calcium silicate board size is generally 1220 mm * 2440 mm calcium silicate The board is not suitable for partitioning the wall, because it is easy to break because of its high hardness. If you do the wall, it is recommended to use gypsum board. Home generally do not use carpentry production wall. Calcium silicate board for large ceilings, and prone to moisture.

- Q: Ceiling gypsum board and plastic plate which cheap?

- Gypsum board cheap, you can consider calcium silicate board, is currently based on the gypsum board based on a fortified gypsum board, tolerance is better than ordinary gypsum board. Do not you know if you want to do the bathroom ceiling? If you want to choose a waterproof gypsum board. The market is well-known brand is "can be resistant" In addition, you said to do the ceiling of the plastic plate, is the aluminum plate? Supplementary description - downstairs № ethereal cents cents, do not understand do not pretend to understand Oh, will not float the first person Ju Ying angle nail hair caused by troubled ~ ~ ~ you said that the aluminum plate is now large Part of the home kitchen and the most commonly used materials, generally square and rectangular two, square about 300MM, it is clear that the landlord does not need this. Landlord, your construction team said gypsum board plus glass, probably they are calculated according to smallpox, which to possession of light, if not, only hanging flat, then they are flicker. Bathroom with aluminum plaster board than the gypsum board to be durable, I used the project, but the specifications for the 1220MM * 2440MM, if your bathroom is not structured, we should pay attention to the hook. You'd better let the workers take the board to give you, or take you to see the site to do, they have a few :)

- Q: It is better to use a glassy magnesium board and a calcium silicate board

- Calcium silicate board. Humid conditions, glass magnesium board components will change the crystal form, the release of magnesium chloride in the formation of frost on the board commonly known as halogen, while losing strength. It is disgraceful to advertise on the upstairs, but the platform is really great, and I am in use, and my whole family is in use. The The

- Q: I have friends want to use calcium silicate board, when the floor with! Do not know if it can? Please talk with friends! Thank you! More

- Simply can not be used ... Calcium silicate board is mainly used in industrial and commercial construction of ceiling ceilings and partitions, home decoration, furniture liner, billboard liner, ship compartment board, warehouse shelves, network Flooring and tunnels and other indoor works of the wall. Calcium silicate board main ingredients and formula: silica powder + calcium powder + natural wood pulp fiber ... when the floor with a few feet with a few ... on the powder The ...

- Q: Fire board fire resistance limit of 3 hours?

- No ... ... two hours have reached a level of fire resistance ... ...

- Q: Living room to do silicon calcium board ceiling, whether need to put putty, brush latex paint?

- Recommended scraping putty, the purpose of many simple, enhanced, and other paint adhesion, hope satisfaction Thank you

- Q: In the vicinity of the decoration shop to see several calcium silicate, what "east", "Baokang" are written green products, what ISO standards. But there is no asbestos, but I estimate the same price with the East (30 less than one, 6mm, 1.22X2.44), but there is no asbestos, There are also asbestos. Does this kind of calcium silicate board do ceiling ceilings? I want to find non-asbestos board, like "Taiwan-wing", that several shop owner said no. The board is too expensive to use. Why in line with national standards, but asbestos is harmful to the human body can be used? Do i use that kind of board now? More

- Asbestos is carcinogenic, building materials can not be used, the national standard is also can not be used. Iso is the quality management system certification, third party, not the country. Before the calcium silicate board because of the hardness requirements will be added, and now seems to have not added, but also not to say, small brand chaos plus what is not good to do the test. Must be used to find a well-known brand it, generally have detected, the key is to find the problem can find a good theory, the alternative to the same product gypsum board, mineral wool board, you can choose ah, you want the kind of , Gypsum board often used, cheap, mineral wool board sound-absorbing good, each have different bar. Landlord can refer to the next

- Q: Decorative gypsum board is good or good calcium silicate board

- Gypsum board and silicate board has its own advantages and disadvantages: gypsum board: advantages: the relative ratio will be more than the order of the dry dry call sucking by environmental protection, easy construction, easy to crack, affordable; Disadvantages: Plate; silicate board: Advantages: good water resistance; Disadvantages: construction is not convenient cutting, dust easily harmful to the human body. Hope that "home staging" decoration can help you to help, hope to adopt!

- Q: I do not know that this question is wrong, is a or a set. Want to know a friend told more

- According to the specifications of the price of 40-160 yuan

1. Manufacturer Overview

| Location | Feicheng city, China |

| Year Established | 1955 |

| Annual Output Value | Below US$1 Million |

| Main Markets | 55.00% China Market 15.00% Mid East Market 9.00% Africa Market 7.00% Korea Market 5.00% Europe Market 5.00% Austraila Market 4.00% Eastern Asia Market |

| Company Certifications | ISO 9001:2000 Certificate , Green Building Materials Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao PORT |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 20 PEOPLE |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 270,000 square meters |

| No. of Production Lines | ABOVE 4 LINES |

| Contract Manufacturing | Design Service Offered ,Quality control offered |

| Product Price Range | MODERATE PRICE |

Send your message to us

Calcium Silicate Boards Model 02 for Exporting

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1Container pc

- Supply Capability:

- 35000Pcs/Day pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords