High-Pressure Decorative Laminates Used Kitchen HPL

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of HPL:

HPL are high quality decoration material , which are widely applied to furniture,kitchen cabinet,cupboard, countertop, window, door skin, wall lining, partition, ship lining ,ceiling, lift lining, shop fitting,shelving, etc .

Fireproof board / refractory plate is base paper after melamine resin and phenolic resin processing, main physical properties is unfolded by the characteristics of the resins. After the melamine resin thermosetting moulding have luster good, good transparency, high surface hardness, wear-resisting, withstand high temperatures, impact resistance, surface pores small is not easy to be contaminated, chemical resistance, water resistance, resistance to solvent, flame resistance and other excellent performance, mechanical strength, electrical insulation, resistance to arc good and is not easy to aging. Phenolic resin thermoset molding after heat and hard performance. Two kinds of resin combination, fireproof board / refractory plate contains both the performance.

2.Feature of HPL:

1) Finishied via impregnating the decorative paper and kraft paper in melamine,drying and high temperature and presure

2) Outstanding resistance to abrasion,high tempreature,dirty,shocking,cigarette ignition and open flame

3) Exceptional mould proof performance ,has very wide application and very big market potential

4) Decorative surface material for both indoor and outdoor use

5) Widely used in surface decoration of rooms, offices, compartments, partitions, kitchens, sideboards, furniture and laboratory table tops

6) wear-resistant, fire-resistant, anti-static, chemical resistant

7) Acid resistance and alkali resistance

8) Abrasive resistance

9) Amazing colors and rich in colors. High glossy and matte is available.

10) Easy to clean

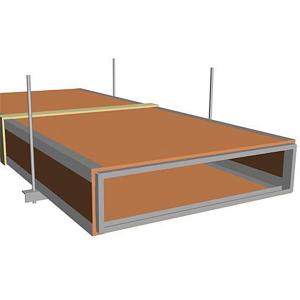

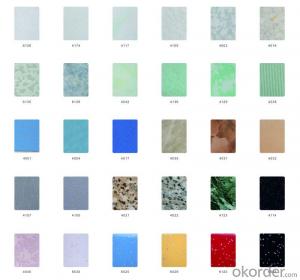

3. Images of HPL:

4.Specifications of HPL:

1. size

1220mmx2440mm 1220mmx3050mm 1310mmx2440mm 1310mm x3050mm

2. thickness

Standard HPL: 0.5mm~1.0mm.

Post-forming HPL: 0.5mm~0.6mm.

Metallic HPL: 0.7mm~1.0mm

Compact: 1.0mm~12mm.

3. color

Solid/plain color, fantastic color, wood grain color, metal, wooden veneer or customized color

4. surface finishing Glossy, Matt, Texture and some other special surfaces.

5. port of shipment Qingdao, China

6. payment 1) T/T 30% in advance, 70% before shipment 2) L/C at sight

7. delivery time It depends on the specific order quantity

8.minimum order quantity 2000 PCS

5.FAQ

1. What kind of certificate do you have?

ISO9001, CE, UL,CARB, CNAS

2. What color can you produce?

Solid color wood grain color or according to customs' requirements.

3. How about the samples?

For the samples, it will be prepared ASAP.

4. Do you charge for the Samples?

According to our company policy, we will charge you the express fee in the first time but the sample will be free. While we start our business, we will reimburse the money for you

5. Can you produce according to customer's design?

Sure, we are professional manufacturer, OEM are welcome. While the beginning you need to pay the moulded open fees and Orders meet the minimum ordering quantity of special products

- Q: The fire resistance of building materials includes the nature of building materials

- Recommended answers are good

- Q: Is it necessary to provide a fireproofing material for decoration works? Such as the use of the hanging plate.

- Must be checked. Another correction, you said the burning board, such as ordinary paper gypsum board, does not belong to fire protection materials, although it belongs to B1 level. Refractory paper gypsum board is the fireproof material.

- Q: Does the ceiling need to brush fire paint?

- According to the construction specifications, when the use of flammable materials for indoor and outdoor decoration, regardless of tooling or home improvement, need to brush fire paint! Flammable materials include wood keel, multi-layer plywood, filled with foam, all kinds of insulation materials, etc.!

- Q: Why do the cabinets in the bathroom use fireproof board material, the bathroom is easy to fire?

- Because the fire board has: waterproof performance. The concept of the fire board is easy to confuse with the professional name. In fact, the fireproof plate we talk about is the fireproof sheet (for example, on the cupboard). It is made of fireproof board (or fire board veneer) and substrate MDF or particleboard) by hot sol high temperature and pressure made by paste. Fireproof board (fire board veneer), also known as fire board, formerly known as thermosetting resin impregnated paper high pressure decorative laminated board, abbreviated as HPL, is a surface decoration with refractory building materials, a rich surface color, pattern and special Physical properties and ease of processing, widely used in interior decoration of the surface material. It is impregnated with phenolic resin for the core (bottom) layer and the amino resin (mainly melamine resin) impregnated paper for the surface layer by heating and bonding at a pressure of not less than 5MPa, the outer layer of one or two A decorative color or pattern. Fire board / fire board is the base paper after melamine resin and phenolic resin processing, the main physical properties are shown by the resin characteristics. Melamine resin thermosetting after a good gloss, good transparency, high surface hardness, wear resistance, high temperature, impact resistance, surface pores are not easy to be pollution, chemical resistance, water resistance, solvent resistance, Such as excellent performance, mechanical strength, electrical insulation, good arc resistance and easy aging. Phenolic resin resin after heat curing and heat and hard and other properties. After the combination of two resins, fire board / fire board both the performance of both.

- Q: What is the fire insulation material

- Materials are: aluminum silicate fiber felt, inorganic mineral raw materials, perlite, glass fiber, ceramic fiber, mullite fiber, basalt fiber, high silicone fiber. Barrier insulation coating is a low thermal conductivity and high thermal resistance to achieve a thermal insulation coating. The most widely used barrier insulation insulation coating is a composite silicate insulation coating. This kind of coating is developed in the late 1980s, with different product names, such as composite magnesium aluminum silicate insulation coating, rare earth insulation coating, coated composite silicate insulation coating. It is made of inorganic and / or organic binder, insulation aggregate (such as sepiolite, vermiculite, perlite powder, etc.) and air entraining agent made of insulation coating. The performance requirements of such coatings can be found in GB / T-1998 "Silicate composite insulation coating". Composite silicate insulation coating Although the thermal conductivity is low, the cost is low, but the drying cycle is long, the impact resistance is weak, dry shrinkage, moisture absorption rate, low bond strength, poor decorative effect. This type of coating is currently used primarily for the casting of molds, tanks and pipes. This coating is currently not used for exterior insulation. In the future through the modified, is expected to be used for external wall insulation system.

- Q: Fire doors with fire insulation materials which?

- Perlite fire door core; glass magnesium fire door core

- Q: Fire safety knowledge

- Basic requirements Primary school students do not play with fire. O (∩ _ ∩) O Thank you

- Q: Polystyrene board is A-class or B-class fire insulation materials

- Should be C level, if the composite inorganic sheet should be B-class material

- Q: What are the fireproof materials for Class A roof insulation?

- Phenolic composite insulation board

- Q: Basement ceiling extrusion board insulation material fire rating What are the requirements? What are the requirements of fire acceptance?

- Belong to the flammable material is absolutely can not be used in the ceiling, to use the flame retardant material Caixing, fire technical specifications are required.

Send your message to us

High-Pressure Decorative Laminates Used Kitchen HPL

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords