High Performance Rotary Vane Vacuum Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

double stage chemical pump1,Material:Aluminum Alloy casing

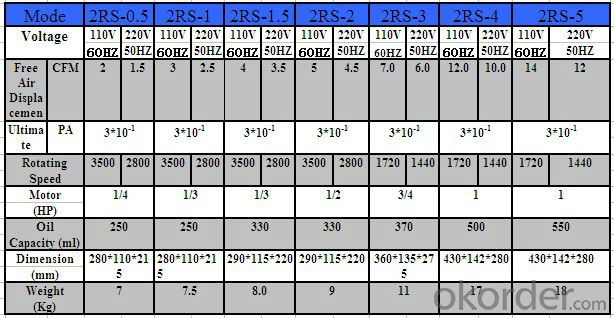

2,Pumping speed:6/7Cfm

3,Warranty:1 year.

4,Minimum order:1 set

◊ Application

chemical vacuum pump

RS Series vacuum pump is compact, light and attractive in design. It uses the big starting torque and is specially designed for low temperature environment. It is guaranteed start normally in winter’s low temperature. It is applicable to vacuum packaging, vacuum freez

This kind of pump is widely used in food packaging, scientific research, medical treatment, electronics, chemicals, medicine and laboratory of universities and colleges.

ing, automobile reparation, gas analysis, medicine mechanism, printing mechanism and other vacuum evacuations.

◊ Technical data

◊ Products' picture

- Q: Variable flow pumps are variable pumps

- To be exact, variable pump means variable displacement. Because if the displacement does not change

- Q: Pump unloading in hydraulic transmission,

- Can be used for short-term shutdown, pump non-stopNo unloading, usually through the overflow valve back to the tank, high pressure, power, at this time insurable pressure, and so on

- Q: What is double hydraulic pump?

- The 2 pumps are all coaxial connected together, driven by a motor, the general gear pump, piston pump

- Q: What are the application areas of pumps?

- Performance range from the pump to see giant pump flow up to hundreds of thousands of cubic meters per hour, while the micro pump flow per hour in a few milliliters; pump from atmospheric pressure up to 19.61Mpa (200kgf/cm2); the lowest temperature of the liquid is transported up to -200 DEG C, up to 800 DEG C. Pumps carry a wide variety of fluids, such as water (clean water, sewage, etc.), oils, acid and alkaline solutions, suspensions, and liquid metals.In the chemical and oil sector production, raw materials, semi-finished products and finished products are mostly liquid, and semi-finished and finished products to raw materials, need to go through a complex process, to pump and provide transportation of liquid chemical reaction of the pressure and flow in the process, in addition, the device also used in many pumps to adjust the temperature.In agricultural production, the pump is the main irrigation and drainage machinery. Rural areas in our country are vast and vast, and a large number of pumps are needed every year in rural areas. Generally speaking, agricultural pumps account for more than half of the total output of pumps.Pumps are also the most widely used equipment in the mining and metallurgical industries. The mine needs pumping and drainage. In the process of ore dressing, smelting and rolling, the pump needs water to supply water first.

- Q: The main factors affecting the performance of centrifugal pumps

- The low specific speed pump, on the other hand, is suitable for smaller flow and higher lift. When the pump outlet pipe diameter at the same time, if the two pumps flow similar, smaller than the speed of small head, shaft power consumption is also large. Generally speaking, the centrifugal pump with smaller revolutions than the impeller has a narrow outlet width and a large outer diameter, and the channel formed by the blade is narrow and long. If the ratio of revolutions is large, the impeller outlet is wide and the outer diameter is small, then the flow passage is short and wide.I hope my answer will be helpful to you. I hope to adopt it!

- Q: What is a positive displacement pump? He Weizheng displacement?

- The principle and structure of displacement pumps are similar to those of hydraulic motors. Positive displacement is the pump outward to provide flow and pressure, that is, conventional pumps. A negative displacement pump is a hydraulic motor that rotates by external pressure and flow

- Q: Water pump does not produce water, what are the reasons?

- 4. as a water inlet valve, check whether it is normal, whether the silted up.5. the installation height of water pump exceeds the allowable suction height of pump, or the suction pipe is too long.

- Q: The working principle of magnetic pump

- Working principle of magnetic pumpN of the magnet (n is even) arranged according to the laws in the magnetic clutch assembly inside and outside the magnetic rotor, the magnet part consisting of magnetic coupling system. When the inside and outside the two poles in different relative displacements, two poles between the angle phi = 0, the lowest energy magnetic system; when rotates to the relative displacement is two poles, pole angle between phi = 2 pi /n, the magnetic system of magnetic energy. Remove the external force, due to the magnetic system of magnetic poles repel each other, magnetic magnet will return to the lowest energy state. So magnets in motion, driven by the magnetic rotor.

- Q: How many square cables does the submersible pump for 7.5KW need?

- I=P/ (1.732Ucos phi) =7.5/ (1.732X0.38X0.85) =13A (calculated according to three-phase city power, power factor 0.85).

- Q: Filter backwash pump for what use, what is the principle of work ah?

- When the filter is in normal operation, the impurity will be trapped in the upstream of the filter (filter medium). As the accumulation of impurities, the filter media will be blocked, and the direct performance is that the circulation will decrease. Usually, when the flow drops to a set point (the industry is usually judged by the pressure drop),

Send your message to us

High Performance Rotary Vane Vacuum Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords