Rotary Vane Vacuum Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

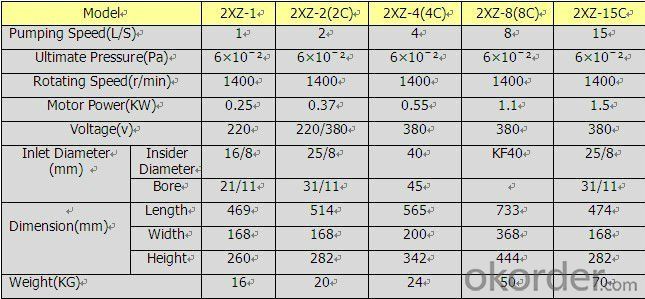

Specifications

1,Pumping speed:2cfm/2.4cfrm.2,Dimension:469x168x260mm.

3,Voltage:220V/380V.

◊ Application

This series of pumps are used for pumping air in sealed vessels. It can be used alone, also can be used as the forepump, diffusion pump, and molecular pump.

◊ Technical data

◊ Products' picture

◊ Main market

America,Russian,Germany,Korea,Bangladesh,Thailand,Myanmar,Kazakhstan,

Mozambique,Malaysia,Greece, Sri Lanka,Syria,Tunisia,Mauritius,Algeria etc.

- Q: What is the difference between swashplate pump and crankshaft pump?

- In hydraulic system:Axial piston pump is the use of parallel with the transmission shaft in the plunger plunger reciprocating movement of the volume changes generated by the work. As the plunger and the plunger hole are circular parts, processing can achieve high accuracy with the high volume efficiency, stable operation, good flow uniformity, low noise, high working pressure, but the hydraulic oil pollution is more sensitive, more complicated structure, high cost.

- Q: What should I pay attention to when buying a pump?

- There are hundreds of water pump manufacturers in China, some of the family owned private enterprises are assembled in some areas, and the quality of the products is very good and bad, which makes it difficult to choose and buy. The main points are as follows:First, according to the required flow, lift, shaft power, efficiency, the necessary cavitation margin (or suction) and the use of conditions, the initial determination of the pump type, name, select the rated value and the required parameters of the same pump.

- Q: If you use an ordinary 15W submersible pump, put it in the tank, if the leakage, the fish will hang it?

- If the fish tank is made of metal, the fish tank is grounded or connected to the zero line, and then the fire line is put into the water, then your fish will be electrocuted immediately. Go back to the submersible pump, submersible pump line and the zero line very close, even if the firing line and the zero line at the same time the leakage occurs, fish could not swim between the firing line and the zero line, so the tank submersible pump leakage will cause the following hazards: 1, electric shock. 2, submersible pump short circuit. 3, the submersible pump serious fever, resulting in water temperature tank.

- Q: Advantages and disadvantages of centrifugal pumps?

- Centrifugal pump; advantages and disadvantages:(1) advantages:The structure of the pump is simple and compact, and the centrifugal pump has small area, light weight, little material consumption and high cost for the foundation. Therefore, the cost of manufacturing and installation is less.For high speed operation, the 2 pole or 4 pole motor can be directly connected. The drive structure is simple and easy to install.

- Q: Excuse me, what is the water pump from the lotus root?

- The pump is automatically coupled by the self coupling device to move downwards along the guide rod to the position, thereby achieving the simple and convenient effect. There's no need to jump into the septic tank when it's time to repair.When you buy a sewage pump, a professional person will ask you what kind of installation you need!

- Q: Roots pump and dry pumpRecently involved in the work of the vacuum pump, don't understand this, is a ads602 vacuum pump, composed of roots pump and dry pump, is pre pumped to the 500mtorr equipment, the main pumping vacuum continues to 10mtorr, where the roots pump and dry pumps must be used? What role they play respectively. The so-called dry pump? Is refers to one kind of the pump, the pump is many dry pump? Also do not understand how the work of automatic switching system for pre pumping, the main pump, pump work alone did not connect system ah (of course there are even a butterfly) teach?

- The front stage pump to a certain pressure to start the roots pump, roots pump has advantages of is at the entrance of low pressure gas pumping speed is high, popular point is in high vacuum pumping speed is still relatively large. With the former pump can achieve different limit the vacuum is different.

- Q: Direct connection pump What is straight pump and non direct pump? What's the difference in structure?

- What is straight pump and non direct pump? Direct coupled pump shaft and the motor shaft is directly coupled with the coupling and non direct coupled pump: pump shaft and motor shaft through the belt pulley, V-belt connection or other forms of transmission. What is the difference in the structure: the direct coupled pump has the advantages of compact structure, simple installation, but the relatively small power; non direct coupled pump: pump and motor is independent, the two transfer torque through the belt, the structure is relatively large, complex installation, general power is relatively large.

- Q: Centrifugal pumps for normal operation, is it reasonable to install valves on their inlet lines? Why?

- Submersible pump is best in the water, if dry pumping will cause burns.

- Q: What flowmeter is installed after the pneumatic diaphragm pump?

- According to your entire pipeline system to flow meter ah!How about the pressure, the material, the digital float or what?You must be sure of the size of the flow

- Q: How to maintain and repair the booster pump of pipeline pump?

- Installation and use1. use rubber washer and bolt to connect the pump flange at both ends and the pipe flange. In order to use and maintenance convenience, in the pump inlet and outlet pipelines should be installed with a regulating valve.2. open the inlet control valve, so that water into the pump, in order to keep the cavity filled with liquid (otherwise it will damage the seal), close the outlet valve.3. turn on the power and make sure the correct turn.4. make sure the pump starts and runs after turning.5. adjust the opening of the outlet valve so that the pump runs near the design point, depending on the rated flow and lift of the pump. [for this reason, it is better to place a pressure gauge near the outlet flange). Note: this pump is strictly prohibited to run without water, so as not to damage the seal.

Send your message to us

Rotary Vane Vacuum Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords