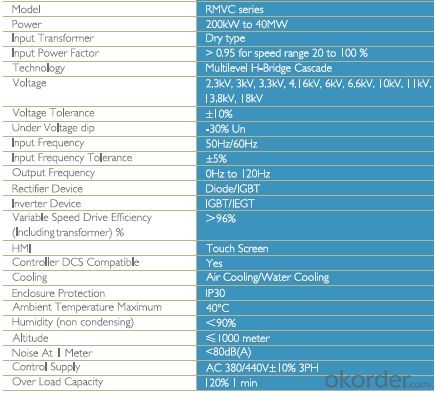

High Medium Voltage Drive 6KV 250KW RMVC4000-A060/320 VFD

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Energy-saving Solutions for Enterprise

1、Program Overview

◆Saving energy achieves 10% -70%

◆The enterprises do not need to pay for expense of equipment manufacture and installation.

◆Enterprises only need to pay the saving electricity expense to our company according to the actual quantity of energy saving after the equipments put into operation.

◆According thousands of the projects’ implementation experiences, such projects recover the investments in three or four years. (Equipment service life is 15 years)。

◆Our company will no longer charge the saving electricity expense after recovering the investment.

The significance of the program:

1)、Concentrate on solving problems of energy conservation, make enterprises’ energy-saving work reach new level and take their social responsibility。

2)、Avoid the enterprises reactive power fine of low power factor caused by electric energy using (according to Ministry of Electric Power and Water Resources, State Price Control Bureau establish the " measures of power factor adjustment expense ").

3)、Avoid the high-energy consumption enterprises are implemented differential prices because of the changes of national power regulation.

4)、For the standard-conforming large-scale (saved energy equal 10 thousand tons standard coal or more) energy-saving technological transformation projects, China will reward the enterprises for energy saving which based on the "Financial Incentives Interim Measure for Energy-saving Technological Transformations" established by Ministry of Finance, the National Development and Reform Commission.( Amount of 200 yuan / ton of standard coal).

5)、Equipments recovery period is generally 3-4 years, each period payment equal to the amount of current energy-saving benefits, and equipments service life are 15 years, so enterprises will gain huge energy-saving benefits.

2、Implementation Process

Energy Audit

Energy Saving Program Design

Construction Design

Equipments Manufacture

Construction and installation

Maintenance and Repair

Energy Monitoring and Efficiency Insurance

Recovery of Program Investment

3、Program Features

High energy-saving efficiency

The project saving rate is generally 10% -30%, highest is up to 70%.

Clients Zero Investment

All works of design, audit, manufacturing, construction, monitoring are handled by RXPE, clients does not require investment.

Energy-saving Guarantee

RXPE promises the amount of energy saving, ensuring that clients’ cost reduction immediately.

Short Investment Recovery Period

The investment recovery period is short, average period is 3-4 years.

Low Risk

Customers do not input large sums of money also can enjoy professional energy-saving products, technologies and services, and the investment risk is very low.

Improvement of Cash Flow

Customers with the support of RXPE approve energy-saving program to improve cash flow, invest the limited funds into other priority investment areas.

Enhance competitiveness through implementing energy conservation, improving energy-saving efficiency, reducing energy costs and enhancing the quality of environment, establish green corporate image and enhance market competiveness.

- Q: 3.7KW inverter with 2.2KW 6-pole motor running to see the inverter shows the current is more than 4A, with the amount of clamp to 2.8A

- Two questions: 1, the inverter output waveform is not a standard sine wave, with the ordinary calorimeter measured value is completely not allowed. The output current of the inverter is the same.

- Q: If it is 8-pole variable frequency motor, enter the motor nameplate parameters in the inverter input for the 4 pole can?

- Motor brand above all, the general number of wrong is the inverter shows the speed is not right, for the speed control requirements are not high places will not be a problem, you can use

- Q: Servo control system can give the inverter signal,

- but want two motor synchronization, it should be impossible, the converter does not reflect so fast, and the speed is not so stable.

- Q: Laptop power adapter (no power supply, but indicator light)

- Notebook power adapter can not charge, but the indicator light does not light the common reasons are: 1, the power adapter is broken or the connector is broken. 2, the power adapter output problem, no output or output is too low, can not give the computer charge. 3, the notebook charging interface is broken, not into the electricity charge. 4, the notebook power management circuit out of the fault, resulting in can not charge.

- Q: Laptop power adapter problem

- First, that is called the transformer, not called the charger, not with you bite the word, but you according to the charger to Taobao search, basically one hundred percent are not found.

- Q: Inverter principle eff23

- Low-voltage general-purpose inverter output voltage of 380 ~ 650V, the output power of 0.75 ~ 400kW, the operating frequency of 0 ~ 400Hz, its main circuit are used to pay straight to pay the circuit. Its control has gone through the following four generations. 1U / f = C sine pulse width modulation (SPWM) control mode is characterized by simple control circuit structure, low cost, mechanical properties of hardness is better, to meet the general requirements of the smooth transmission speed, has been in various fields in the industry Widely used. However, this control mode at low frequencies, due to the lower output voltage, the torque by the stator voltage drop is more significant, so that the maximum output torque reduction.

- Q: The inverter flat rate transferred to 29, on the submersible pump to burn the coil ?!

- 1. submersible pumps are generally the problem, far away from the reflection voltage, the pump insulation breakdown, in particular, to better pump. 2. Distance away, the inverter and pump connection thicker. 3. Then on the output filter.

- Q: How to choose a power adapter

- There are several principles for replacing the power adapter. 1. The voltage is the same or similar. Your computer's nominal input voltage is 16V, and the following adapter's rated output voltage is 20V, the difference is large, can not be replaced, may damage the computer. 2. The plug has the same polarity. Your notebook marked on the polarity of the mark is inside and outside the negative, that the adapter I really can not see what is the polarity of the label, you take a closer look if the symbols and notes on the notebook is not the same, it is absolutely not. 3. The rated output current of the power adapter can not be less than the rated input current of the computer. Your computer marked the maximum input current is 3.36A, then you buy the power adapter when you want to buy the output current greater than or equal to 3.36A, the bigger the better, but the greater the output current that the greater the rated power, too much Waste, and very cumbersome, generally slightly larger than on the line, leaving some margin.

- Q: Why the notebook power adapter can not be universal

- First, the interface is different Most laptop power adapter brands have different interfaces, which means that other brands of power adapters can not be plugged into your laptop for power supply. The interface is relatively safe, because at least you will not plug in the current or voltage does not meet the power adapter to the laptop power supply, which led to computer hardware damage.

- Q: Please recommend a high performance laptop power adapter?

- Power adapter can recommend you what model you get what model ah he is a standard can not just recommend

Send your message to us

High Medium Voltage Drive 6KV 250KW RMVC4000-A060/320 VFD

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches