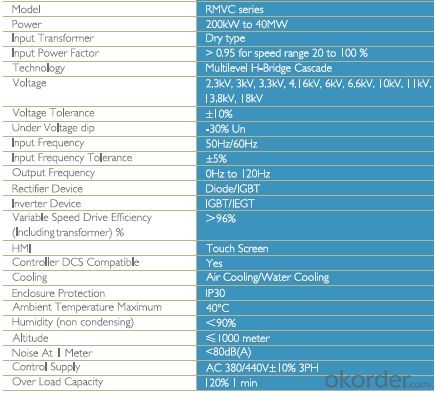

High Medium Voltage Drive 3KV 500KW RMVC4000-A030/630 VFD

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Energy-saving Solutions for Enterprise

1、Program Overview

◆Saving energy achieves 10% -70%

◆The enterprises do not need to pay for expense of equipment manufacture and installation.

◆Enterprises only need to pay the saving electricity expense to our company according to the actual quantity of energy saving after the equipments put into operation.

◆According thousands of the projects’ implementation experiences, such projects recover the investments in three or four years. (Equipment service life is 15 years)。

◆Our company will no longer charge the saving electricity expense after recovering the investment.

The significance of the program:

1)、Concentrate on solving problems of energy conservation, make enterprises’ energy-saving work reach new level and take their social responsibility。

2)、Avoid the enterprises reactive power fine of low power factor caused by electric energy using (according to Ministry of Electric Power and Water Resources, State Price Control Bureau establish the " measures of power factor adjustment expense ").

3)、Avoid the high-energy consumption enterprises are implemented differential prices because of the changes of national power regulation.

4)、For the standard-conforming large-scale (saved energy equal 10 thousand tons standard coal or more) energy-saving technological transformation projects, China will reward the enterprises for energy saving which based on the "Financial Incentives Interim Measure for Energy-saving Technological Transformations" established by Ministry of Finance, the National Development and Reform Commission.( Amount of 200 yuan / ton of standard coal).

5)、Equipments recovery period is generally 3-4 years, each period payment equal to the amount of current energy-saving benefits, and equipments service life are 15 years, so enterprises will gain huge energy-saving benefits.

2、Implementation Process

Energy Audit

Energy Saving Program Design

Construction Design

Equipments Manufacture

Construction and installation

Maintenance and Repair

Energy Monitoring and Efficiency Insurance

Recovery of Program Investment

3、Program Features

High energy-saving efficiency

The project saving rate is generally 10% -30%, highest is up to 70%.

Clients Zero Investment

All works of design, audit, manufacturing, construction, monitoring are handled by RXPE, clients does not require investment.

Energy-saving Guarantee

RXPE promises the amount of energy saving, ensuring that clients’ cost reduction immediately.

Short Investment Recovery Period

The investment recovery period is short, average period is 3-4 years.

Low Risk

Customers do not input large sums of money also can enjoy professional energy-saving products, technologies and services, and the investment risk is very low.

Improvement of Cash Flow

Customers with the support of RXPE approve energy-saving program to improve cash flow, invest the limited funds into other priority investment areas.

Enhance competitiveness through implementing energy conservation, improving energy-saving efficiency, reducing energy costs and enhancing the quality of environment, establish green corporate image and enhance market competiveness.

- Q: Can the laptop's power adapter be used for years?

- Most laptop power adapters can be used for 100 ~ 240V AC (50 / 60Hz). Basically, most of the notebook computers are external power supply, with a power cord and the host connection, which can reduce the size and weight of the host, only a very small number of models built in the host power.

- Q: What is the application of variable frequency speed control?

- Frequency conversion is to change the power supply frequency, thus regulating the load, play a lower power consumption, reduce losses, extend the service life of the role. Frequency translation. Frequency conversion technology is the core of the inverter, through the conversion of the power supply frequency to achieve the motor speed regulation of the automatic adjustment of the 50Hz fixed-line frequency to 30-130 Hz change frequency. At the same time, also make the power supply voltage to adapt to the range of 142-270V, to solve the power grid voltage instability caused by electrical work problems. By changing the AC frequency of the way to achieve the AC control technology is called frequency conversion technology.

- Q: Is the speed of the motor controlled?

- Slip motor is composed of ordinary squirrel cage asynchronous motor, electromagnetic slip clutch and electrical control device composed of three parts. Asynchronous motor, the stepper motor is used as the prime mover, and when it rotates, the armature of the clutch is rotated together. The electric control device is a device that provides the excitation current of the slip clutch excitation coil. Electromagnetic slip clutch, which includes armature, magnetic pole and excitation coil three parts.

- Q: I have a 11KW-4 pole inverter, now with the 4KW-4 pole motor, what impact?

- that is, the load is very heavy; caused by over-current burning inverter

- Q: Inverter signal line analog 4-20mA connection positive and negative can be reversed?

- Analog input signal is particularly vulnerable to external interference, so the general use of twisted shield as a signal line; and wiring as short as possible, generally not more than 20 meters; if some use conditions are vulnerable to external serious interference, the analog signal Side need to add a filter capacitor or ferrite core.

- Q: 5.5 kW 4-pole motor with the fastest speed can exceed the rated speed?

- Can not be exceeded Although the inverter can run out of the motor rated speed as the motor will soon burn You want your running speed of 2m / s you have to run 5m / s so go eggs do not pull the

- Q: On the notebook power adapter output current and voltage issues

- On the real virtual cable that adapter is rectifier filter output, no regulator, the notebook internal regulator, the adapter does not need to regulator. 3.25A is smaller than 4.5A, because the adapter has a power margin that can be used. Summer attention to touch the adapter surface is overheating. Conditional or buy a large number of good current.

- Q: The Schneider inverter reports the nlp command

- Schneider inverter reported nlp ??? main circuit no electricity 1 re-power up 2 connected to the DC reactor terminals PO, PA / + between the short wiring, the main circuit can not be powered

- Q: Do you need to rectify before switching?

- There are two ways to convert frequency, that is, cross and cross the intersection, the latter need a direct current, need no rectification, depending on your DC situation.

- Q: Can the inverter be used to control the speed of the DC motor?

- For the brush commutation DC motor, the speed of the output torque in a certain circumstances and the input voltage related. For this type of motor, use the inverter to control the output of the rectifier device that supplies power to the motor, which can control the speed. For the brushless DC motor, the controller is in accordance with a certain law to change the form of stator winding power supply to produce a rotating magnetic field to drive the rotor rotation. That is, the DC motor controller outside the part of the AC motor and the structure and the principle has not much difference (see below. For such motors, with the inverter to replace the controller, and control the same as the AC motor Control the speed.

Send your message to us

High Medium Voltage Drive 3KV 500KW RMVC4000-A030/630 VFD

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords