High & Low Chrome Alloyed Casting Grinding Ball with Dia0.75’’-Dia0.6’’(ISO9001:2008)

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

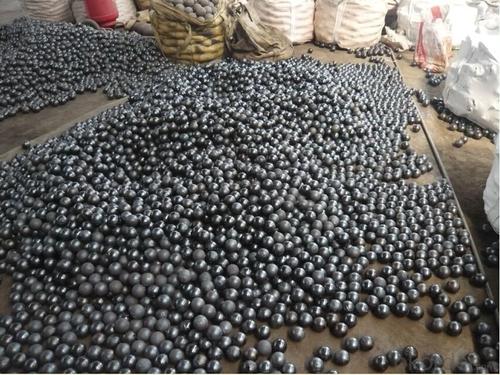

High & Low Chrome Alloyed Casting Grinding Ball with Dia0.75’’-Dia0.6’’(ISO9001:2008)

1. Chemical Composition of High & Low Chrome Alloyed Casting Grinding Ball with Dia0.75’’-Dia0.6’’(ISO9001:2008)

Item | C | Cr | Si | Mn | S | P | Cu | Mo | Hardness |

Low Chrome | 1.8-3.5 | 1-3.5 | ≤1.2 | ≤1.5 | ≤0.15 | ≤0.15 | ≤0.5 | ≤1.0 | ≥45 |

Medium Chrome | 1.8-3.3 | 4-9 | ≤1.2 | ≤1.8 | ≤0.15 | ≤0.15 | ≤1.0 | ≤1.5 | ≥50 |

High Chrome | 1.6-3.3 | 10-15 | ≤1.0 | ≤2.5 | ≤0.10 | ≤0.10 | ≤1.5 | ≤1.0 | ≥55 |

Higher Chrome | 1.6-3.3 | 15-18 18-27 | ≤1.0 | ≤2.5 | ≤0.10 | ≤0.10 | ≤1.5 | <2.0 | ≥60 |

2. Weight and Quantity of High & Low Chrome Alloyed Casting Grinding Ball with Dia0.75’’-Dia0.6’’(ISO9001:2008)

No. | Diameter (mm) | Weight of each (kg) | Pcs/ton |

1 | Ø10 | 0.0135 | 74073 |

2 | Ø12 | 0.0181 | 55248 |

3 | Ø15 | 0.0242 | 41322 |

4 | Ø20 | 0.0322 | 31056 |

5 | Ø25 | 0.063 | 15873 |

6 | Ø30 | 0.11 | 9091 |

7 | Ø40 | 0.257 | 3891 |

8 | Ø50 | 0.50 | 2000 |

9 | Ø60 | 0.867 | 1153 |

10 | Ø70 | 1.37 | 729 |

11 | Ø80 | 2.05 | 487 |

12 | Ø90 | 2.90 | 345 |

13 | Ø100 | 4.00 | 250 |

14 | Ø110 | 5.30 | 188 |

15 | Ø120 | 6.80 | 147 |

16 | Ø125 | 7.75 | 129 |

17 | Ø130 | 8.74 | 114 |

3. Mechanical Properties of High & Low Chrome Alloyed Casting Grinding Ball with Dia0.75’’-Dia0.6’’(ISO9001:2008)

Model | Mechanical properties | Microstructure | |

HRC | Times of falling (3.5m) | ||

Low Chromium | ≥45 | ≥8000 | P+C |

Medium Chromium | ≥50 | ≥12000 | P+C |

High Chromium | ≥55 | ≥15000 | M+C |

Higher Chromium | ≥60 | ≥22000 | M+C |

4. Production Process of High & Low Chrome Alloyed Casting Grinding Ball with Dia0.75’’-Dia0.6’’(ISO9001:2008)

Raw material(waste steel,waste iron,iron alloy)factory inspection→blending→melt→composition inspection→casting→cooling and solidification→demould→clean and polish→inspection→quenching(increase hardness)→hardness inspection→tempering(eliminate stress)→inspection→warehousing

5. Features of High & Low Chrome Alloyed Casting Grinding Ball with Dia0.75’’-Dia0.6’’(ISO9001:2008)

1) High hardness and resistance

2) Good even wear

3) No breaking

6. Applied Fields of High & Low Chrome Alloyed Casting Grinding Ball with Dia0.75’’-Dia0.6’’(ISO9001:2008)

1) Mining

2) Cement plants

3) Power stations

4) Chemical industry and machinery

7. Packing Methods of High & Low Chrome Alloyed Casting Grinding Ball with Dia0.75’’-Dia0.6’’(ISO9001:2008)

- Q: What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- The aim is to make the grain fine and distribute the carbide evenly. The difference between normalizing and annealing is that normalizing cooling rate is slightly faster than annealing cooling rate, so normalizing structure is finer than annealing structure, and its mechanical properties are also improved. In addition, normalizing furnace cooling does not occupy equipment and has higher productivity. Therefore, normalizing may be used instead of annealing as much as possible. The main application areas of normalizing are as follows: for low carbon steel, after normalizing, the hardness is slightly higher than that of annealing, and the toughness is better. It can be used as the pretreatment of cutting. Used for medium carbon steel, instead of quenching and tempering, as the final heat treatment, or as an induction heating method before surface hardening. Used for tool steel, bearing steel, carburizing steel, etc., it can eliminate or restrain the formation of network carbide, so as to obtain the good organization of spheroidizing annealing. For cast steel, the microstructure can be refined and the machinability can be improved. Used for large forgings, which can be used as final heat treatment, so as to avoid larger cracking tendency during quenching.

- Q: The casting defects of pores, trachoma how to repair?

- Metal repair can be used to fill the repair. Airhole 2mm following LT102 recommend the use of liquid metal repairing agent.

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: What kind of casting process is used for cast iron parts? And what are the cast steel parts adopted?

- The types and uses of foundry sand according to the mineral composition of different silica sand and non siliceous sand is divided into two categories. The main mineral composition of silica SiO2.: natural silica sand used for non-ferrous metal casting, cast iron and steel castings in small sand and core sand. The selection of natural silica sand: used in organic matter as the binder of various sand and core sand. The artificial sand for sand and core sand castings. Non siliceous sand and non siliceous sand have many kinds and different uses. Limestone sand: crushed by limestone, the main mineral composition is CaCO3, used for casting sand and core sand. Zirconium sand: the main mineral composition is ZrO2 SiO2, used for large steel castings and alloy steel pieces of core sand or sand surface sand, or powder used as coating. Magnesia: the main mineral composition is MGO, used for high manganese steel casting surface sand, core sand, and its powder can be used as coating. Chromite ore: the main mineral composition is chromite FeO. Cr2O3, used for large or special casting steel surface sand, core sand, its powder can be used as coating.

- Q: After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- The finish of reaming depends on the material and the sharpness of the reamer, as well as the speed and speed of the top and bottom. Marine machine tool

- Q: Where is the precision casting factory?

- Shandong, DongyingThe birthplace of precision casting

- Q: What kind of flaw detector is better for casting parts?

- Casting using the detector test, you must first determine the detection process, such as the detection of surface and near surface crack defects, such as casting, recommended by CYD-3000, or CYD-5000 mobile magnetic testing machine for testing.

- Q: Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- Our country has a national standard for casting tolerance levels. This national standard applies to you in malleable iron, grey cast iron, and ductile iron.

- Q: How to solve casting defect casting?

- Different defects, different solutions, some shortcomings, the current domestic level can not be resolved

- Q: Shandong foundry, casting small pieces of precision casting

- Small foundry in Shandong too much, like many of us in Qingdao, then Dongying Changshun investment casting is a home, they are also casting precision casting equipment, specifically what I recommend that local enterprises, far is not convenient,

1. Manufacturer Overview

| Location | Zhangqiu, China |

| Year Established | 1995 |

| Annual Output Value | 150,000M.T. |

| Main Markets | 40%,South America; 30%,South Africa; 15%,Southeast Asia; 5%, Europe Area; 5%, North America; 5%, Other Areas |

| Company Certifications | ISO9001:2008;SGS Test Report |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao;Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | 25 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 68,000m2 |

| No. of Production Lines | 15 |

| Contract Manufacturing | |

| Product Price Range | $700/M.T.-$1200/M.T. |

Send your message to us

High & Low Chrome Alloyed Casting Grinding Ball with Dia0.75’’-Dia0.6’’(ISO9001:2008)

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords