Manhole Covers Ductile Iron EN124 GGG40 On Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

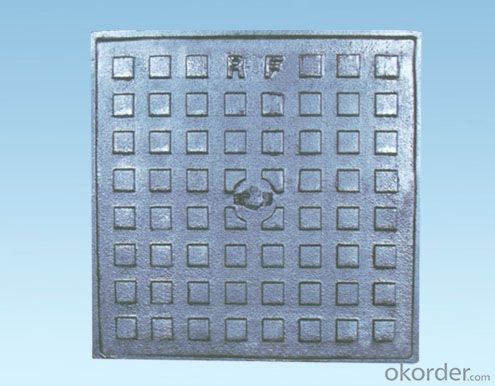

1.Cast Iron Manhole Cover Description :

A manhole cover is a removable plate forming the lid over the opening of a manhole, to prevent anyone or anything from falling in, and to keep out unauthorized persons and material.

Designs: based on EN124 standard and according to customer's drawing or samples.

Color: black, Grey, green, blue and Marble , etc.

Inspection: in-house or the third party as per customer's request.

2.Main Features of the Ductile Iron Manhole Cover:

1) Product information:

Manhole Covers are manufactured for construction and public use. Manhole Covers shall be smooth and free from sand holes, blow holes, distortion or any other defects

2) Material

a) Ductile Iron GGG500-7 & 400-12

b) Grey Iron GG20

3) Designs .

a) EN124 A15, B125, C250, D400, E600 and F900

b) A60005 for casting design

c) Major standards designs available

d) As per customers' drawings or samples

3.Manhole Cover Images:

4.Manhole Cover Specifications:

Manhole cover are manufactured for construction and public use. Manhole cover shall be smooth and free sand holes, blow holes, distortion or any other defects

A) Ductile iron GGG50

B) Grey iron GG20

C) EN124 Class B125 C250 D400 F 900, with different size and grammage, or as customers' requirement.

D) as per customers' drawing or samples

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

Q. Can I fit a square manhole cover into a round chamber?

A. Yes, there are a select few manhole covers which are square-to-round, meaning they will fit square or round chambers.

Q. I have a heavy traffic manhole cover but it has been broken by a forklift, why?

A. Forklifts have solid wheels which apply pressure differently to standard pneumatics and therefore covers must be specially adapted to suit this.

Q. I’ve measured my clear opening size but none of your covers match it, can you offer anything?

A. It’s likely that your cover is quite old and in imperial measurements which are no longer manufactured. However, we can offer bespoke solutions with manhole covers made to the specification you require.

- Q: The casting defects of pores, trachoma how to repair?

- Metal repair can be used to fill the repair. Airhole 2mm following LT102 recommend the use of liquid metal repairing agent.

- Q: Domestic large steel castings factory which is better, recommend!

- Do the casting manufacturer of large steel castings, Hunan Jinsha heavy industry science and technology limited company, heard that their professional only more than 1 tons of steel castings, anyway, 150T just big, the company won a lot of foundry industry patents should be good. At least spend money on research and development, then the quality should be all right.

- Q: What are the casting parts processing engineering?

- According to the classification of process methods, sand casting and special casting.

- Q: Question, such as title, I hope I don't copy the definition of rolling and casting in Baidu encyclopedia, thank you

- Service performance: heat conductivity, friction reduction, shock absorption, heat resistance and corrosion resistanceTo compare these properties, it depends on the specific material, structure, and use of the parts. Otherwise, there is no comparisonS

- Q: How to distinguish the forging parts and casting parts accurately

- To distinguish from the use of materialsForging materials are mainly made of carbon steel and alloy steel of various components, followed by aluminum, magnesium, titanium, copper and their alloys. The original state of the material is rod, ingot, metal powder and liquid metal. The materials needed for casting are mostly metal, wood, fuel, molding materials and so on. In contrast, the forging parts rarely produce dust, harmful gas and noise, etc., and play a more obvious role in environmental protection. Of course, because of this, the price of forged parts on the market is higher than that of castings.

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- according to the comprehensive consideration of factors such as yield, size of workpiece commonly used on the market the crawler shot blasting machine has Q324, Q326, Q328, Q3210, and each time the amount of their treatment were 125KG, 200KG, 400KG, 600KG, the specific use of what types also need to be determined according to the actual situation

- Q: Where is the precision casting factory?

- Everywhere is. Look what you want to do

- Q: Why should pig iron be used in casting?

- Not necessarily is iron, steel, stainless steel, aluminum, copper can be cast iron, is cheaper, and better properties of cast out, for example, is not easy to rust, high strength, easy processing and so on, and is the only iron iron cast out, it is not necessarily the raw pig iron, plus some other material

- Q: What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Proofing? In the casting industry is not called proofing, proofing is generally used in the printing industry, that is, according to the customer's drawings or samples, to do a first piece, to provide customers with the inspection process to meet their requirements;In the foundry industry, providing prototypes is sometimes difficult:1, customers if the provision of mold, it would be best, at this time, sample costs are very low, and almost the same as your regular products;2, the customer does not provide the mold, but in business relationships, your factory and not very sure must take this one, it requires your leadership decision-making, is free or low cost, or by a strict process offer (of course sample);3, not all of the casting process to provide samples are difficult, like lost foam can directly make a white NC prototype, and then assembled pouring, this is her unique advantages, first cost less than the opening process and so on;If you don't understand, you can continue to question me

- Q: Younger brother is to do casting valve, precision casting parts, the valve internal sand serious, but the appearance is very standard, this is why, for God answers, thank you!

- Valve sand core mold drying is not in place, excessive water content

Send your message to us

Manhole Covers Ductile Iron EN124 GGG40 On Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords