Electro- Galvanized Steel Sheet in Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electro- Galvanized Steel Sheet in Coils Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Electro- Galvanized Steel Sheet in Coils:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

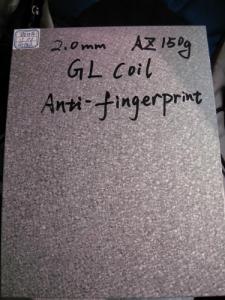

3.Electro- Galvanized Steel Sheet in Coils Images

4.Electro- Galvanized Steel Sheet in Coils Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Electro- Galvanized Steel Sheet in Coils

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: I have been searching on pots and pans, how can I find out if it's really stainless steel, someone told me if a magnet sticks to it it's real stainless steel is this true?

- Mel: okorder /

- Q: What are the common manufacturing defects in steel coils?

- Common manufacturing defects in steel coils include surface defects such as scratches, pits, and scale, as well as shape defects like buckling, waviness, and edge cracks. Additionally, internal defects such as voids, inclusions, and segregation may also be present in steel coils.

- Q: How are steel coils classified based on their thickness?

- Steel coils are classified based on their thickness into different categories such as light gauge, medium gauge, and heavy gauge.

- Q: Yes, I understand it can weaken steel greatly. But can it MELT steel? (key word: melt)

- The okorder /.. A flame from a wick burning kerosene demonstrates incomplete burning, hence sooty, yellow and a lower temperature flame like a candle. Kerosene in a cup or puddle only burns while it is hot enough to give off vapor. The vapor is all that is burning. It is not very hot, as it is not the right mixture with air. It may not even give off enough heat to keep the kerosene itself hot enough to keep burning. A kero blow torch flame might be typically 1100-1300°C but parts can reach 1760°C or more in some cases.

- Q: help me and my twin love this cutie in our form !? how do we steel hime from bitchey rebecca!? X X X xX

- Well i never had to steel a guy because if I have to go through all of that obviously hes not for me. Also, I never been that desperate. But if you can steel the boy your going to share him with your twin? thats not very... normal. Also if you can steel the guy, how long do you think hes going to stay with you before someone else takes him. Also you should read more so you can spell better because cute guys try to take advantage of dumb girls.

- Q: How are steel coils used in the production of construction equipment?

- Steel coils are used in the production of construction equipment as they provide a reliable and cost-effective material for manufacturing various components. These coils are often processed and shaped into specific parts, such as frames, chassis, and heavy-duty structures, which make up the foundation and framework of construction equipment. The high strength and durability of steel coils ensure that the equipment can withstand heavy loads, extreme conditions, and repetitive use, making them essential in the construction industry.

- Q: How are steel coils protected against corrosion?

- Steel coils are protected against corrosion through a process known as galvanization, where a layer of zinc is applied to the surface of the steel. This zinc coating acts as a barrier, preventing the steel from coming into direct contact with moisture and oxygen, which are the main causes of corrosion. Additionally, other protective measures such as painting or coating the steel with anti-corrosion materials may also be employed to further enhance its resistance against corrosion.

- Q: I like steel strings but don't want to get a new guitar. Is that my only option?

- It will permanently ruin the guitars neck. Acoustic guitars have an adjustable metal rod in them called a “Truss Rod” that allows the neck to withstand steel string tension. How about putting on high tension nylon strings ?

- Q: What is the process of recoiling steel coils?

- The process of recoiling steel coils involves rewinding or unrolling large steel coils to create smaller, more manageable coils. This process is typically carried out in steel processing plants or coil service centers. The first step in the recoiling process is to identify the appropriate coil to be recoiled. This selection is based on factors such as coil size, weight, and quality. Once the coil is chosen, it is placed onto a recoiling machine, which is equipped with various mechanisms to facilitate the recoiling process. The recoiling machine consists of a mandrel or drum, around which the coil is wound or unwound. The coil is secured onto the mandrel, either by mechanical clamps or hydraulic pressure, to ensure it remains stable during the recoiling process. In the case of rewinding or recoiling a large coil into smaller coils, the machine starts by unwinding the original coil. This is done by rotating the mandrel in the opposite direction, causing the coil to gradually unroll. As the coil unwinds, it passes through various straightening and flattening mechanisms, which help to ensure the coils are produced with consistent dimensions and quality. Once the original coil is completely unwound, the machine starts the rewinding process. The smaller coils are created by winding the steel strip onto the mandrel in a controlled manner. The speed and tension of the rewinding process are carefully regulated to prevent any damage to the steel strip. During the recoiling process, various quality control measures are implemented to ensure the produced coils meet the desired specifications. These may include monitoring the thickness, width, and surface quality of the steel strip, as well as conducting periodic inspections to detect any defects or irregularities. Once the rewinding process is completed, the smaller coils are typically removed from the mandrel and prepared for further processing or shipment. This may involve applying protective coatings, labeling, or packaging the coils, depending on their intended use. In summary, the process of recoiling steel coils involves unwinding large coils, straightening and flattening the steel strip, and rewinding it onto a mandrel to create smaller, more manageable coils. This process requires specialized machinery and careful control to ensure the quality and consistency of the recoiled coils.

- Q: Hi can someone help me pleaseis there any available data for mechanical behaviour of recycled steel, i need to compare them with new steel.

- Most recycled steel is blended with new steel at the steel mill. Scrap steel that is reused directly doesn't change it properties because it has been used. That is unless it has been in certain environments such as ones with hydrogen, hydrogen sulfide etc. Then the steel can become brittle. You might look for information on the National Association of Corrosion Engineers (NACE). They have lots of information on metals and what causes problems.

Send your message to us

Electro- Galvanized Steel Sheet in Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords