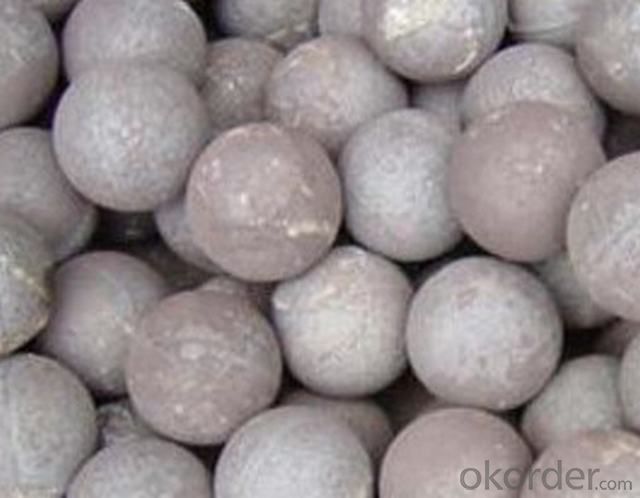

High Chromium Cast Grinding Ball with Top Quality Steel as Raw Material withch can be uesed in Mines

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Applied Field of Forged Grinding Ball with High Performance, Low Breakage And Good Waer-resistance

1) Power Plant, 2) Mineral Processing,

3) Refractory Factory, 4) Cement Plant

2. Feature of Forged Grinding Ball with High Performance, Low Breakage And Good Waer-resistance

1) In general, grinding steel ball has high hardness: surface hardness to 58-65 HRC, volume hardness of 56-65 HRC

2) impact toughness high: impact toughness more than 12 J / cm2.

3) broken rate is low: the actual broken rate is not higher than 0.5%.

4) loss of grinding forged steel ball round rate is low.

3. Chemical Composition of Forged Grinding Ball with High Performance, Low Breakage And Good Waer-resistance

Product | Brand | Chemical composition(%) | ||||||||

C | Si | Mn | Cr | Mo | Cu | Ni | P | S | ||

Special high chrome casting iron ball | Cr26 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | >23.0-30.0 | 0-3.0 | 0-1.2 | 0-1.5 | ≤0.10 | ≤0.06 |

Special high chrome casting iron ball | Cr20 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | >18.0-23.0 | 0-3.0 | 0-1.2 | 0-1.5 | ≤0.10 | ≤0.06 |

Special high chrome casting iron ball | Cr15 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | >14.0-18.0 | 0-3.0 | 0-1.2 | 0-1.5 | ≤0.10 | ≤0.06 |

High chrome casting iron ball | Cr12 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | >10.0-14.0 | 0-3.0 | 0-1.2 | 0-1.5 | ≤0.10 | ≤0.06 |

High chrome casting iron ball | Cr8 | 2.1-3.3 | ≤2.2 | 0.3-1.5 | 7.0-10.0 | 0-1.0 | 0-0.8 | - | ≤0.10 | ≤0.06 |

Middle chrome casting iron ball | Cr5 | 2.1-3.3 | ≤1.5 | 0.3-1.5 | 4.0-6.0 | 0-1.0 | 0-0.8 | - | ≤0.10 | ≤0.10 |

Low chrome casting iron ball | Cr2 | 2.1-3.6 | ≤1.5 | 0.3-1.5 | 1.0-3.0 | 0-1.0 | 0-0.8 | - | ≤0.10 | ≤0.10 |

Casting ball | QTB | 3.2-3.8 | 2.0-3.5 | 2.0-3.0 | - | - | - | - | ≤0.10 | ≤0.03 |

Casting ball | QTM | 3.2-3.8 | 2.0-3.5 | 2.0-3.0 | - | - | - | - | ≤0.10 | ≤0.03 |

- Q: How is the silicon sol precision casting part priced? What is the price per ton of casting? Such as 304 material.

- The material is usually steel material price plus the cost (per ton of 2.5-3 million, plus profit).In the Yangtze River Delta region, generally 304 casting price of about 5-5.5 million / ton.The price will be higher if the parts are complex, or a piece weighs less than 100 grams.

- Q: How do casting parts remove stress?

- Annealing treatment, according to different casting annealing treatment, eliminate thermal stress, if need to restore hardness or increase hardness, and then quenching treatment

- Q: Why do cheap cars like stamping parts instead of casting parts?

- We usually say that the stamping is usually refers to the cold stamping parts, for example, a piece of iron, wants to turn it into a fast food dish, it must design a set of mold, mold is working face plate shape, the pressure plate mold, it becomes you want the dishes, this is the cold stamping die stamping is the direct use of metal materials.Automobile stamping parts are mainly classified according to process, and can be divided into two major parts: separation process and forming process.

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: What are the casting parts tested?

- The surface brightness, appearance, size, chemical composition, weight, material, surface defects, internal defects, seals need to be checked, leakage, etc.

- Q: Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- The choice of shot blasting machine, this is according to the workpiece size, yield, whether can collision, and the working time and other factors considered, while the price of different blasting machine are not the same, but the vast majority of small castings used crawler shot blasting machine,

- Q: My parts complex, machining costs are relatively high, so want to cast, but the surface needs anodizing, what material will be better?

- The common material that can be anodized is aluminum alloy. It is recommended to use casting aluminum alloys, such as ZL102 and ZL105, which are commonly used as cast aluminium alloys. The processing of aluminum casting is easy. After processing, the surface of the whole part can be anodized. The color can be chosen.

- Q: Younger brother is to do casting valve, precision casting parts, the valve internal sand serious, but the appearance is very standard, this is why, for God answers, thank you!

- Increase the refractoriness and looseness of core sand

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1983 |

| Annual Output Value | Above US$100 Million |

| Main Markets | South Asia, South Asia, Central America, Western Europe, Eastern Asia, Mid East, Oceania, Africa |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English;Chinese;Japanese;Korean |

| b) Factory Information | |

| Factory Size: | Above 20,000 square meters |

| No. of Production Lines | 8 |

| Contract Manufacturing | Grinding steel balls;Grinding steel cylpebs;Grinding media;Grinding meida ball |

| Product Price Range | Average |

Send your message to us

High Chromium Cast Grinding Ball with Top Quality Steel as Raw Material withch can be uesed in Mines

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords